Heat Treat Radio #107: Stop-Off Coatings 101, with Mark Ratliff

Needing to learn more about the fundamentals and latest developments of stop off coatings? Mark Ratliff, president of AVION Manufacturing Company, Inc., applies his background in chemical engineering to understand and create what makes the best stop-off coatings/paints for carburizing and other heat treat processes. In this episode, Mark and Heat Treat Radio host, Doug Glenn, uncover the varieties of coatings, their uses, and the future of coating solutions.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

The following transcript has been edited for your reading enjoyment.

Chemistry in Coatings: Mark Ratliff’s Start in the Industry (00:22)

Doug Glenn: I have the really great honor today of talking with Mark Ratliff from AVION Manufacturing. We’re going to do a “painting class” . . . kind of, but not really. Industrial paint — we’re going to talk about stop-off paints and things of that sort.

Mark has been working at AVION, currently located in Medina, Ohio, since 1994. He graduated with a Bachelor of Science degree in chemical engineering from the University of Cincinnati. Prior to that — I did not know this about you, Mark — he worked at Shore Metal Treating with your father, huh?

Mark Ratliff: That’s correct, yes.

Doug Glenn: How long was he there?

Mark Ratliff: Well, he started the company. I went working there and was loading baskets of parts since I was about 8 years old. He would pay me $5.00 for a basket, “under the table,” and that was a lot of money back then. I was really rich, at the time!

Doug Glenn: That’s pretty cool. It is very interesting to see people’s backgrounds and how they got involved in the industry. A lot of people start young, you know? You may win the record though — 8 years old! The labor board may be calling about your childhood.

Why Use Stop-Off Paints? (01:54)

Let’s talk today. Technically, we want to talk about something that not everybody may know about, and I think you and your company are kind of experts on these things, and that’s stop-off paints. Just from a 30,000-foot view — and you don’t have to go into a lot of detail here, Mark — what are stop-off paints and why do we use them?

Mark Ratliff: Stop-off paints are protective barrier-type coatings. What they do is prevent either carburization or the nitriding process from entering into the steel. They were created probably well over 50 years ago as a replacement for copperplating these parts. In the past, a long time ago, they would copperplate the part that they did not want carburized or nitrided. That’s a time-consuming process as well as being very expensive. The stop-off coatings were developed as an economical alternative to copperplating.

Doug Glenn: When you say “copperplating,” does that mean it was actual thin sheets of copper metal?

Mark Ratliff: That’s correct, yes.

Doug Glenn: And you actually had to wrap whatever you did not want nitrided or carburized in this copper and that would keep it from nitriding?

Mark Ratliff: That’s correct, yes.

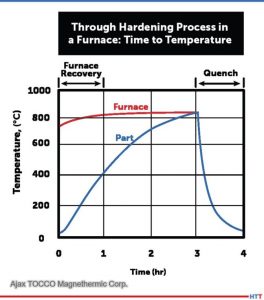

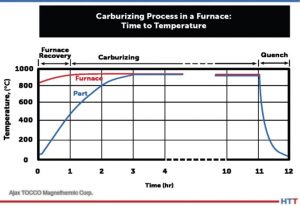

Doug Glenn: Just in case people don’t know — but I would imagine that most people that are listening to this do know — nitriding and carburizing are both surface hardening technologies in which either nitrogen (in the case of nitriding) or carbon (in the case of carburizing) are infused into the surface. That, of course, gives improved wear properties, typically corrosion properties to those areas that receive the infusion of the metal.

Why do people not want the nitrogen or carbon to be infused to certain areas of the part?

Mark Ratliff: When you harden a part, as with carburization or nitriding, a lot of times hardness equates to brittleness. So you may induce certain stress in various parts, in various areas.

Also, if you want to do a post-heat treatment machining on the part, it would be virtually impossible if that part were carburized or nitrided because the surface is so hard that the tool can’t cut through it to do further machining on the part.

“If you want to do a post-heat treatment machining on the part, it would

be virtually impossible if that part were carburized or nitrided because the surface is so hard that the tool can’t cut through it to do further machining on the part.”— Mark Ratliff, AVION Manufacturing

Doug Glenn: Gotcha.

Can you give a couple examples of parts, and if you can do a description of where on those parts you might apply a stop-off coating?

Mark Ratliff: Well, a lot of times the end user (the customer) is painting an end of a shaft where he’ll heat treat the shaft and make the shaft harder, but he wants to spin a thread on the end of that shaft. That’s a prime example of why you would use a stop-off coating.

A lot of times, the parts are made with the threads already on, but you don’t want those threads to be hardened because, again, hardness equals brittleness, and those threads would crack off after heat treatment. That would be an area where you would apply a stop-off coating.

Physical Properties of Stop-Offs (05:27)

Doug Glenn: Tell us a little bit about the actual physical “properties" of these stop-off coatings. We also call them “stop-off paints.” I’m assuming a lot of times these are just painted on — it’s a liquid format.

Mark Ratliff: They are all supplied in liquid form with the viscosity ranging right around 3500–8500 centipoise (cP). For the carburizing stop-off, we have two different kinds. (This is not new in the industry; most people know the formulations of the stop-offs.)

We have boric acid-based stop-offs; we have two different kinds of that — a waterborne and a solvent borne. The idea behind the boric acid-based stop-offs is that as the boric acid thermally decomposes, it creates a boron oxide glass. This glass is actually the diffusion barrier of the carbon. What’s nice about the boric acid-based stop-offs is that they’re water washable after the heat treatment process; the coating and the residue can get washed off.

Another type of stop-off coating that we have is based on silicate chemistry. A silicate chemistry is basically like putting a glass on the part. It’s more of a ceramic-based coating. It works very, very well, but the drawback of the silicate-based stop-offs is that you have to bead-blast the parts after heat treatment; it does not wash off in water.

Doug Glenn: So, you’ve got to brush it off.

Mark Ratliff: You’ve got to brush it off, mechanically, correct.

Doug Glenn: That’s interesting.

When I think of painting something on and then putting it into a furnace, the first thing I think of is that paint is going to get completely obliterated in the furnace. But you just kind of answered that question. Those things will either transform into a glass or a ceramic of some sort after they’ve been in high heat for a while, and that’s what creates the barrier.

Mark Ratliff: That’s correct.

You have the active ingredient in the stop-offs — you either have the silicate or you have the boric acid. Those are the active ingredients. The vehicle that the paint itself — be it the water-based latex or the solvent-borne bead — those do, indeed, get charred off. They get burned off, leaving the active ingredient behind.

Doug Glenn: Are you able to use either of those — the water-based or the solvent-based — in vacuum furnaces? Do you have any trouble with off-gassing and things of that sort?

Mark Ratliff: Yes, a little bit. We’ve got to be careful in the vacuum furnace market because you do have the off-gassing. The combination of the vacuum and the heat at once can cause the coating to boil and blister. We do recommend pre-heat treatments when doing a vacuum operation.

Doug Glenn: And the pre-heat just kind of helps it adhere to the part without the blistering, I guess?

Mark Ratliff: That’s correct. And it drives off a lot of the residual water or solvent that might be left in the coating.

Different Chemistry, Different Technology: Plasma Nitriding Stop-Off Coatings (08:32)

Doug Glenn: Okay, good.

Now I understand that there is a new product coming out on the nitriding end of things. Can you tell us a little bit about that and why you’re developing it?

Mark Ratliff: We’ve been making a nitriding stop-off coating since 1989 when we came out with our water-based version. We actually had it patented. We were the first on the market with a water-based nitriding stop-off. This particular stop-off has been used in the industry for 45 years now.

We got called by a current customer asking, “Hey, do you have a plasma or an ion-nitriding stop-off?” At the time, we did not. So, we developed a new plasma — aka, ion-nitriding — stop-off, and that’s a different chemistry, different technology. It is going to be available in the market very soon.

Doug Glenn: Interesting.

I’m curious about this: Are stop-off paints used more in carburizing or nitriding?

Mark Ratliff: By far, carburizing — it’s probably 10 to 1 carburizing to nitriding, for sure.

Doug Glenn: Okay, gotcha.

So, you’ve been doing this for 30 or some years, right?

Mark Ratliff: It will be my 30th anniversary in the month of April.

Doug Glenn: Very nice! Well, congratulations.

Mark Ratliff: I did work for my father prior to that, when he ran AVION for many years before that.

Doug Glenn: Well, congratulations, first off — that’s good. It shows longevity, which is good.

Memorable Moment of Innovation (11:11)

Doug Glenn: Has there been a memorable challenge that you had to deal with, with these stop-off paints?

Mark Ratliff: One thing I’m particularly proud of, Doug, is we always had the water-based carburizing stop-off coating — both varieties — the boric acid-based and the silicate-based. I had a few customers reach out to me and say, “Hey, we’re doing heat treatment for the aerospace industry or for the automotive industry, and they don’t like water-based coatings on their parts,” because you run into corrosion, you run into rust, and so forth and so on. So, these customers asked me to create the solvent-borne, which we did about seven or eight years ago.

One thing I’m particularly proud of is, I got called by the Fiat Chrysler plant in Michigan (they’re going by Stellantis, now), and unbeknownst to them, their current stop-off provider, at the time, changed the formulation. (That was due to the REACH regulations in Europe.) Since they changed the formulation, Stellantis started seeing all these problems. So, they reached out to me and asked, “Do you have an equivalent? We’d like a solvent-borne stop-off.” I was quick to respond, “Oh, by the way, yes, we do. And yes, our product is better,” because even though it’s solvent-borne, we created a nonflammable stop-off coating. In addition to being nonflammable, the solvent that we used in the coating is VOC exempt — VOC meaning volatile organic compounds — which are basically air pollutants that people want to avoid when using these stop-off coatings.

Doug Glenn: Okay, very interesting. I was going to ask you — because I saw on your website — about your green label, which you kind of hit on with the VOC part, but can you tell us a little bit about the green label products that you have and why you’re calling them “green label”?

Mark Ratliff: We called it “green label” a long time ago — that was our original stop-off which kicked off our business 50+ years ago. But I think you’re referring to our eco green label which we created about two years ago.

We’ve been getting a lot of pressure to remove VOCs from our coatings. Clients like John Deere and Caterpillar said, “Hey, we love your coating, but if you could do anything to get the VOCs out of it, we’d really appreciate it.” So, that was one of the biggest goals and one of the biggest accomplishments — to create a coating that didn’t have any of these VOC or HAP (hazardous air pollutants)-type solvents in the coating, and we have successfully done that.

Doug Glenn: That’s good. Especially in the ‘green movement’ that’s going on today, that’s obviously very important.

What coating solution should heat treaters be looking at, in the near future? Is it just VOC stuff, the lack of VOC, or what?

Mark Ratliff: Well, yes, of course. I mean, we’re proud to say that all of our coatings are virtually VOC-free. We are still making the original green label because some customers are not happy to change, so we still offer that. But every single one of our coatings right now have a less than 10 gram/liter VOC threshold, and we’re really quite proud of that.

But, you know, as you’re talking about new coatings coming to the market, we’re coming out with the plasma nitriding stop-off. But we’re also looking into a stop-off for salt bath carburizing. We’ve had a couple people reach out to us, just recently, asking, “Do you have a coating that we can use to paint on the parts that go into a salt bath carburizing operation?”

Doug Glenn: That would be interesting because there is a bit of abrasion going on there, yes?

Mark Ratliff: There is, correct.

Final Questions: Supply Chain, Technical Assistance, and Target Markets (14:51)

Doug Glenn: Now, that’s interesting.

I have two additional questions for you. One has to deal with supply chain issues. Have you guys had any issues with being able to deliver quickly or anything of that sort, ala Covid?

Mark Ratliff: Sure. Right after Covid, we had trouble getting the main ingredient for the carburizing stop-off coating which is boric acid. Currently, I have three suppliers that supply that to me, and there was a point in time where none of them could get the material because the manufacturer of this product was not delivering east of the Mississippi. So, I had to do several days of researching and scrounging around, and I found a distributor in California that said, “Yes, we can get it to you, but you have to buy a whole truckload, which we were very happy to do.”

Doug Glenn: Yes, you take what you can get, at that point.

But no issues now?

Mark Ratliff: No, everything is pretty much back to normal. I mean, gone are the days where you could pick up the phone and get material delivered to you in three days, but most of our raw materials get delivered in under two weeks, and we keep a pretty adequate inventory of all of our raw materials so that we don’t run out of anything.

Doug Glenn: So, you get the raw materials. Do you do your own formulations there? I mean, do you actually do the mixing and all that stuff?

Mark Ratliff: We do. Everything is all done here, in-house, correct.

Doug Glenn: Finally, technical assistance and competency on your guys’ part: Do you have people on your staff — yourself or others — that if a customer calls in with an issue, you can help talk them through it?

“[Look] at the copperplating method: It’s, number one, very expensive, and number two, from what I’ve been told, it’s not very environmentally friendly — you’re working with a lot of hazardous ingredients, hazardous waste."

— Mark Ratliff, AVION Manufacturing

Mark Ratliff: Absolutely. So, I’m the “go to guy” here at AVION. If anyone has any technical questions, I’m the one that’s going to be answering them. And if it’s something where I need to come out to the plant, I’ll get in my car or get on a plane and visit that customer, if the quantity of it dictates that.

Doug Glenn: Yes, sure; it’s got to be a good business opportunity, obviously. But I’m sure you can use the phone to answer questions too.

Mark Ratliff: Yes, most of the time it’s by phone.

Doug Glenn: So, Mark, in the marketplace, is there an ideal client, someone who maybe should be considering stop-off paints that isn’t currently using it? Is there someone out there that you would say, “Hey, you know, if you’re doing this, maybe you ought to think about stop-off paints, if you’re not already doing them.”

Mark Ratliff: Well, I would certainly still target those that are copperplating. Look at the copperplating method: It’s, number one, very expensive, and number two, from what I’ve been told, it’s not very environmentally friendly — you’re working with a lot of hazardous ingredients, hazardous waste. So, those are the types of people that I will continue to target for stop-off coatings.

Doug Glenn: Well, Mark, listen, that’s great. Hopefully, this has been a good primer for people who didn’t know what stop-off paints/coatings were, and hopefully they can get ahold of you if they need something. I appreciate you being with us.

Mark Ratliff: Okay, thank you very much, Doug. I appreciate it myself.

About the Expert

Mark Ratliff started at Avion Manufacturing in 1994 after earning his bachelor’s of science degree in Chemical Engineering at the University of Cincinnati. Prior to getting his degree, Mark spent many of his summer breaks working for his father at Shore Metal Treating where he gained a good deal of knowledge about the heat treating industry.

Contact the expert at mark@avionmfg.com or www.avionmfg.com

Search Heat Treat Equipment And Service Providers On Heat Treat Buyers Guide.Com

Heat Treat Radio #107: Stop-Off Coatings 101, with Mark Ratliff Read More »