Heat Treat Radio #88: Lunch & Learn — 3 Most Underrated Processes

Get ready to watch, listen, and learn about the three most underrated heat treat processes in today’s episode. This conversation marks the continuation of Lunch & Learn, a Heat Treat Radio podcast series where an expert in the industry breaks down a heat treat fundamental with Doug Glenn, publisher of Heat Treat Today and host of the podcast, and the Heat Treat Today team.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

Doug Glenn: There are some underdog heat treat processes out here. I’d like to get to three today. What do you think is number one?

Michael Mouilleseaux: Let’s start with stress relieving. All ferrous materials, all steels, during the course of manufacturing or processing, have some residual stress that is left in them. A common thought about stress relieving is you have a weldment, and you stress relieve it so that the weldment stays.

There is a mechanical action in the material during any cold working operation (cold forging, stamping, fine planking, etc.) because it's done at ambient temperature. Those all impart stress on the part.

Machining, turning, grinding. . . all of those things impart stress into a part. How is that relieved? It can be done thermally, or it can also be done mechanically. Thermally is the most common of them.

What I would like to talk about is not so much stress relieving weldments, it is stress relieving manufactured components. If you’re going to have a comprehensive analysis of the heat treat operation that needs to be performed on a manufactured component, a gear, a shaft, something of that nature, they need to take into consideration what are the prior existing stresses in the part. Then what effect is that going to have on the part?

Many times during the course of my career, I’ve had a customer come to me and say, “The part I gave you was correct, and you’ve given it back to me and then fill-in-the-blank. It’s warped, it’s changed size, it’s shrunk, all of those things.” What have you done in your heat-treating process? You have to back up all the way to the beginning of how this part was manufactured and deal with all of those component steps in order to answer that question properly.

Stress relieving is one of the answers. It’s not the answer. It’s not the only answer, but it is one of them that has to be considered.

Doug Glenn: For those of us who might not know what a “stress” is in a part, can you simply explain? For example: a coat hanger. If I bend it, is that inducing stress? Is that what’s causing stress? What makes stress in a part?

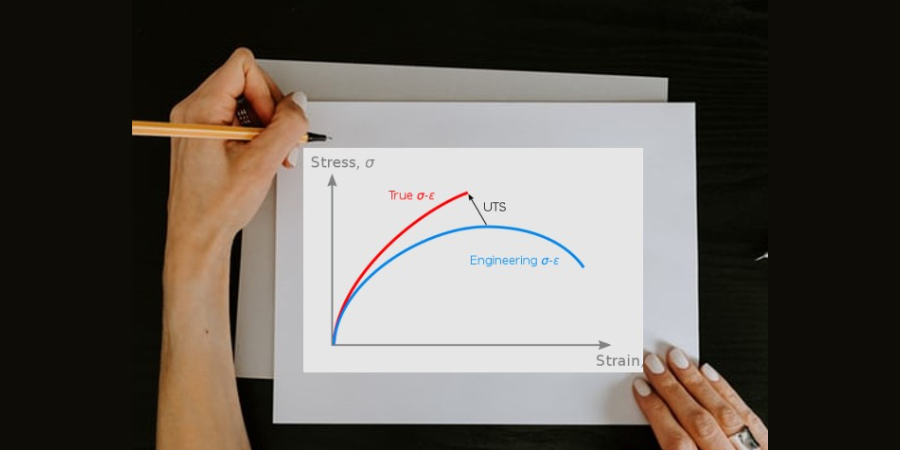

Michael Mouilleseaux: You’ve cold-worked the part. In the cold working, you’ve passed the yield strength. You’ve bent it, and it’s not going to snap back. You’ve cold-worked it enough that you’ve actually got plastic deformation, and there is stress.

Doug Glenn: That’s one way we get stress. That’s the mechanical way of getting stress.

Michael Mouilleseaux: Right. Now, consider stamping. Even though a stamping is flat (because the die has come down in the perimeter of that and maybe internal holes and things), where you’ve sheared the material, you’ve imparted stress there.

If you harden it or case harden it or whatever you might do with that stamping, you have to take into consideration how much stress is there. If I don’t relieve it, is it going to do that at some point in the part’s future that’s going to be detrimental to the part?

Doug Glenn: When you get a stress in a part, that’s the area that’s a weak spot, right? It potentially could break before other parts?

Michael Mouilleseaux: At the absolute extreme, that could happen, yes. More often than not, what you have is an area that’s been cold worked, and it’s been deformed. When it stresses, it’s going to somewhat relieve itself. It may not relieve itself 100% all the way, but it will somewhat relieve itself. Whatever shape of form you’ve put that part into; it’s not going to hold that form forever.

Alyssa Bootsma: You mentioned that stress relieving is not the only way to alleviate the problems. What would be some alternatives to stress relieving?

Michael Mouilleseaux: Thermal stress relieving is, by far, the most common. There is a process that’s called vibratory stress relieving. In order to relieve the stresses in a part, you have to impart some energy in it. Something between 800 and 1200 Fahrenheit is typically used in stress relieving. That thermal energy goes into the part and relieves the stresses.

You could also do that mechanically by a high frequency vibration. It’s not as common. I believe that it’s actually a propriety process, if not patented. It would be for something that you did not want to subject to 800-1000 degrees Fahrenheit because that doesn’t come for free. Obviously, in a ferrous material at that temperature, you’re going to have some oxide forming on the part. You may or may not be able to utilize the part in its final function with that oxide on it.

Those are typically the two ways to do it. Can it occur naturally over time? Yes, but none of us have that kind of time.

Alyssa Bootsma: You did mention how it doesn’t necessarily mean that it’s more likely to break if that part is not relieved, but what parts would suffer the most if this process was done incorrectly?

Michael Mouilleseaux: Probably weldments. The detrimental effects of not having stress relieved of weldment would be the most significant. In welding there is a whole range of temperatures proximate to the weld — everything from room temperature to maybe 3000 degrees. That whole range of things changes the structure of the steel.

Leaving it in that condition makes it susceptible to any number of things — embrittlement, accelerated corrosion, and others. There is every reason to stress relieve something like that and almost no reason not to.

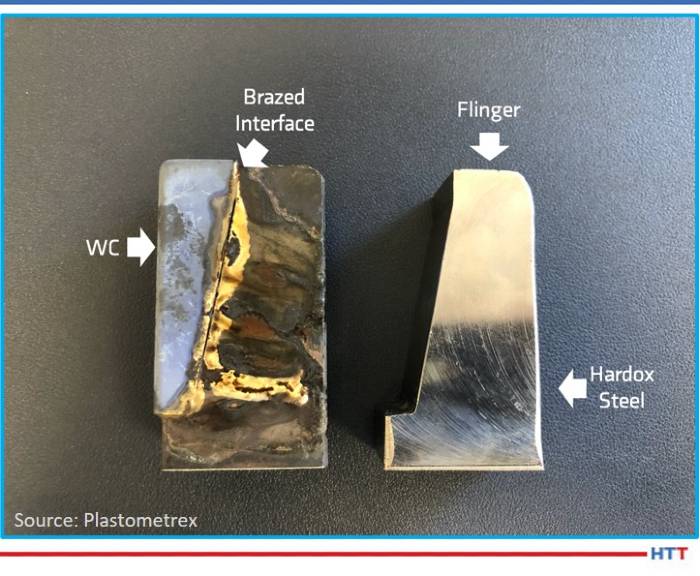

Doug Glenn: That’s weldment. Do they do a stress relieve after a braze as well, or is that not as common?

Michael Mouilleseaux: Typically not. The reason for that is, in brazing, the entire assembly is brought up to the same temperature. Then it’s cooled at the same rate.

Bethany Leone: I have two brief questions: 1. How long does stress relieving typically take? 2. Would we see the effects of incorrect stress relieving, or failure to, once something goes to quench?

Michael Mouilleseaux: The first question — would you necessarily see a failure? Those would be extremes. I’m more familiar with stress relieving fabricated components that are machined. Take a gear. They forge a blank and maybe machine out the center of the gear, machine the exterior of the gear, cut the teeth in a shaping operation (a hobbing operation or skiving or other ways of generating teeth).

"You have this part, and it needs to be heat treated. To assume that all of those machining operations would have no effect upon that whatsoever is not a good thought."

Then comes a comprehensive program of evaluating how best to heat treat a part. It doesn’t matter if it’s out of a medium carbon alloy steel or it’s a low alloy steel and we’re going to carburize it, what’s critical is that it’s going to get heated. The material is going to transform into austenite and cool rapidly or quench it. That’s what’s going to cause the hardening operation on the part.

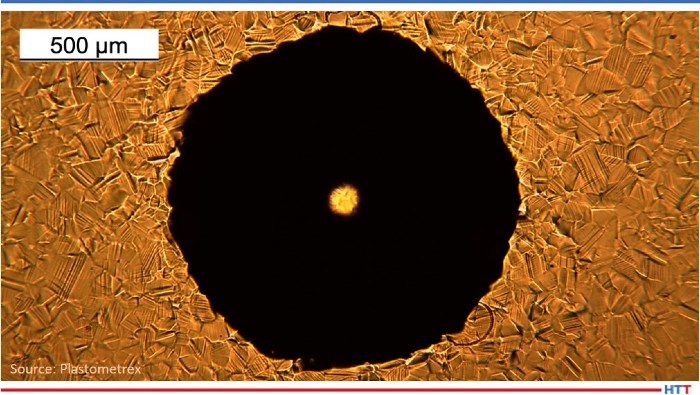

In doing that, there are going to be changes in size. In hardening a part, you get a volumetric expansion. Thin sections are not going to expand as much as larger sections. A misnomer is, “You shrunk the hole.” You haven’t shrunk the hole! The material around the hole has expanded, the exterior portion of that area has increased, and the interior portion of that has decreased.

If you have a spline in that hole, now you’re on for something else because their teeth form in that spline. If it’s in a long section, then how uniform it’s been hardened has to do with whether or not it goes out of round or their taper. There are any number of things there. Those are all critical to the operation of this gear.

But what we have to take into consideration is the broaching operation. We drill a hole, and we put a broach bar through it and cut all of these teeth. All of that has imparted stress in the part.

One of the preliminary things that needs to be done is you stress relieve the part and give it back to the manufacturer. They measure it and say, “Oh, oh, it changed!” That change is not something the heat treater can do anything about. That’s the physics of what happens when you work-harden a part. This all has to be taken into consideration and addressed before we talk about what’s the heat treat distortion.

Bethany Leone: And the other question I had: How long does it take to stress relieve?

Michael Mouilleseaux: Typically, if it’s held at an hour or two at temperature, it’s thought that 1000 degrees for an hour at temperature will relieve most stresses.

Now, in a component part, we’re going to go higher in temperature. Although we’re not going to go high enough to austenitize the part, we’re going to go high enough in temperature that we know we’re going to relieve it.

Michael Mouilleseaux: They’re cousins. Stress relieving, the implication is that you are doing that simply to relieve prior existing stresses. In annealing, the implication is that you are going to reduce the hardness of the microstructure for the purposes of machining or forming. In annealing, there’s subcritical and supercritical and a hundred different flavors of that.

Doug Glenn: I’m trying to get a sense of what percentage of heat treating is stress relieving. Is it super popular? It seems to me it would be very common.

Michael Mouilleseaux: Interestingly enough, I’m going to say that the majority of the gearing product that we do, we incorporate a stress relief in the initial stages of heat treating. By putting the part in and raising the temperature to a stress relieving temperature and then taking it up into the austenitizing temperature, you’re not shocking the part. You’re not just taking it from room temperature to carburizing temperature or hardening temperature, and thereby you’re reducing the thermal stresses. So, you’re not imparting any more.

Doug Glenn: Stress relieving may often be done as a part of another process?

Michael Mouilleseaux: It can be, definitely.

Doug Glenn: Let’s move on to the second forgotten heat treatment.

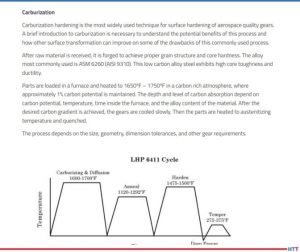

Michael Mouilleseaux: I don’t know about forgotten. I’m going to say that it’s getting short shrift, and that is conventional atmosphere carburizing. What’s sexy in heat treating? It’s low pressure carburizing and gas quenching. It’s growing very rapidly and it’s being used in a lot of applications.

We’re subject to the same ills that Mark Twain identified years ago, and that is, “To a man with a hammer, every problem looks like a nail.” Low pressure carburizing and gas quenching, they can save every distortion issue that’s ever been known to man in heat treating, and they don’t. They are other tools in the box, applicable to a lot of application. They are great processes, very targeted and specific. You know, sometimes you need a screwdriver instead of a hammer.

Conventional carburizing: It’s been around for a hundred years. What’s different today than what it ever was? Certainly it has everything to do with the control systems that are being used to control it. It’s eminently more controllable now than it has ever been. It is a precision operation, and it has many applications. By the way, it’s far more cost effective than carburizing would be. In vacuum carburizing, the cost is multiple; is it two, three or four times more expensive? It depends on how you calculate cost of capital and all of those things. But it’s a multiple, more expensive than conventional carburizing.

Doug Glenn: To do vacuum carburizing?

Michael Mouilleseaux: To do vacuum carburizing, yes. Should it be used in every application? I’m going to say no. Are there definite applications? Definitely.

Doug Glenn: Conventional carburizing, atmosphere carburizing is another area largely forgotten. I know it’s quite popular, but it’s not getting a lot of discussion these days.

Michael Mouilleseaux: Right. Any time there is an issue with a carburized part, everyone knows to ask the question, “Why don’t you vacuum carburize it?” The answer to that is, “Let’s solve the problem before we decide what it is that we need to do.”

Karen Gantzer: Mike: At a very basic level, can you explain why do heat treaters use endothermic gas?

Michael Mouilleseaux: In atmosphere carburizing, we need a method of conveying carbon to the part so that we can enrich it; that’s what carburizing is. The carburizing portion of the atmosphere in endothermic gas is carbon monoxide. Carbon monoxide — that’s the reaction at the surface of the part — the carbon diffuses into the part. That’s how you generate a case in the part.

It’s a relatively inexpensive form of carburizing. You use natural gas and air in what we call a “generator”, and that’s how endothermic gas is generated. Then, it’s put into the furnace. There’s almost no air in a furnace. People think you’re going to look in a furnace, and you’re going to see flame. You never do because the amount of oxygen in the furnace is measured in parts per million. You put additional natural gas to boost the carburizing potential of the atmosphere, and that’s what allows you to diffuse carbon into the part. That is the case hardening process.

Doug Glenn: Conventional carburizing is done in a protective atmosphere, typically as an endothermic atmosphere which is rich in carbon monoxide.

Michael Mouilleseaux: Yes.

Doug Glenn: A lot of times we’re worried about oxygen in the process because of potential oxidation. Why is it that we use a gas that has oxygen in it to infuse carbon? I know it’s got carbon, but it’s also one C and one O, right? Don’t we run into problems of potential oxidation?

Michael Mouilleseaux: In endothermic gas there is hydrogen, nitrogen and carbon monoxide, and there are fractional percentages of carbon dioxide and some other things. The hydrogen is what scrubs the part; that’s what kind of takes care of all of the excess oxygen. The nitrogen is just a carrier portion of it, and the carbon monoxide is what is the active ingredient, if you will, in the carburizing process.

The carbon diffuses into the part. If there is an oxygen, it’s going to combine with the hydrogen. Preferentially, you’re not going to have any free oxygen in the furnace, but you can have a little water vapor. One of the ways of measuring the carbon potential in the furnace is a dewpoint meter. The dewpoint meter is measuring the temperature at which the gas precipitates out, and that’s a monitor or a measure of the carbon potential.

Doug Glenn: A dewpoint analyzer helps you know what the carbon potential is.

Michael Mouilleseaux: Yes. It’s not as good as an oxygen analyzer.

Doug Glenn: An oxygen probe.

Michael Mouilleseaux: The oxygen probe is in the furnace, measuring constantly. You get a picture; you have continuous information. It’s not that there aren’t continuous dewpoint analyzers, but you have to take a sample from the furnace. It has to be taken to an analyzer wherein it is then tested. Best case scenario is you have both of them and you compare the two of them. That gives you a really great picture of what the atmosphere conditions are in the furnace.

Alyssa Bootsma: For a bit of background knowledge: What is the difference between endothermic gas and exothermic gas?

Michael Mouilleseaux: Endothermic gas has 40% hydrogen and 20% carbon monoxide. 60% of it is what you would call a reducing atmosphere. The way that you make endothermic atmosphere is 2.7 parts of natural gas and one part of air. You heat it up to 1900 degrees, and it’s put through a nickel catalyst. You strip off the hydrogens. The gas dissociates, and that’s what results.

Exothermic gas is six parts of air in one part of natural gas. You only have 10 or 15% hydrogen. Although it’s not an oxidizing atmosphere, it’s very mildly reducing.

It can be used in annealing, clean annealing. If you’re annealing at 12-1300 degrees or more or in that ballpark, that kind of an atmosphere is going to keep the work clean. If you did it in air, it would scale.

Bethany Leone: Is there an industry (automotive, aerospace, energy) that it would be most helpful for those parts to be typically atmosphere carburized, and/or is it just generally helpful for all types of industries?

Michael Mouilleseaux: First of all, the transportation industry is the lion’s share of heat treating — automotive, truck, aircraft. Atmosphere carburizing is extremely popular and commonplace in those industries.

If we said that we were going to have a seminar and I’m going to talk about atmosphere carburizing. Somebody else is going to talk about low pressure carburizing in a vacuum furnace. Everybody’s going to go over to the other room. Folks feel they already know what this is all about, and they know what all the problems are. They think that the vacuum carburizing is going to solve all of them.

When you work with the proper kinds of controls, the proper kinds of furnace conditions, the right way of fixturing parts and cleaning them ahead of time, you can have extremely consistent results. You can have extremely clean parts, and you can have very good performance from these things.

What the Europeans call “serial production”: we run millions of gears per year, and we have very consistent case steps in hardnesses as a result of good practice. All of these things need to be monitored and controlled and taken care of. But the results are also very consistent and very predictable.

Doug Glenn: Interesting. And it’s more cost-effective, I’m guessing. Conventional atmosphere carburizing, on a per part basis, is going to be substantially less expensive.

Michael Mouilleseaux: We’ve looked at it. Is it two times, is it three times, is it four times more expensive to vacuum carburize a part? The answer is yes. The question is, does that component justify that? There are any number of them where it does.

Doug Glenn: Where it does justify it?

Michael Mouilleseaux: Yes, absolutely.

Doug Glenn: Let’s go on to #3, the third underdog in heat treating.

Michael Mouilleseaux: Number three is marquenching. Marquenching, martempering, and hot oil quenching are in the family that describes this process.

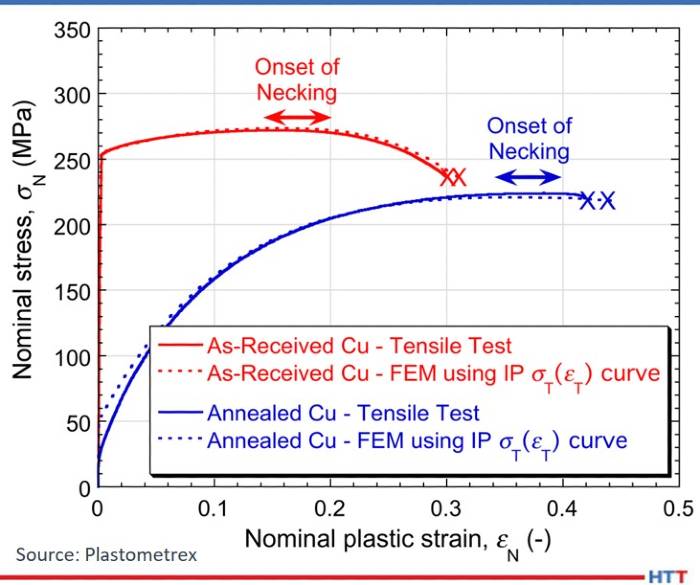

Martempering is different than just quenching in oil, quenching in regular fast oil. Regular oil is going to be 100 vis, and it’s going to be from 90 degrees to 150 degrees. All kinds of low hardenability, or parts that don’t have a lot of adherent alloy in them, you utilize that so that they can be fully hardened. But components that are distortion-critical, quenched in that manner in regular oil, there is going to be a high degree of distortion. How is that addressed? It’s addressed in marquenching.

Let’s take an example of a carburized gear. A carburized case is heated to 16-1700 degrees and carburized. Best practice would say that I’m going to reduce the temperature before I quench it, and then I’m going to quench it in oil. Do I understand that: I have to have loading that spaces the part; and the parts need to be fixtured in such a way that, physically, they don’t impede on each other; and I get full flow of oil, and all of those things? The answer is yes, yes, and yes.

The martensite starts to form in the case at, let’s say, 450 and it’s plus or minus 25 or 30 degrees or so. Take that part and put it into the range where the martensite starts to form, and hold it at that temperature and let the entire part cool down to that 450 degrees where the martensite is starting to form. Then we remove the part from the furnace and allow it to cool in air to room temperature. At that point, the cooling rate is much lower than it it’s going to be where you’re conducting that in a liquid medium. Because of that, the stresses are going to be less, the distortion is going to be less. That is a strategy for reducing distortion.

You ask, “Why do you need to do that.?” Again, the man with the hammer: I’m going to gas quench this part because I have the opportunity to gas quench it, and the gas quenching doesn’t come for free. The shadowing effects of a gas flow has to be taken into consideration, orientation of the parts. There are a number of things that need to be taken into consideration.[blocktext align="left"]There are a number of applications where in marquenching a part, the distortion can be controlled. We process a lot of gears, and we maintain 20/30 microns of total distortion in ID bores on gears. It is a viable way of controlling distortion.[/blocktext]

Doug Glenn: We say marquenching.

Mike Mouilleseaux: Or martempering or hot oil quenching.

Doug Glenn: The “mar” part of that comes from martensite? I want have you explain what exactly martensite is. But is that where it comes from?

Mike Mouilleseaux: Yes. We’re getting right into the start of the martensite transformation.

Doug Glenn: There are different microstructures in metals. Austenite is pretty much the highest temperature, and it’s where the molecules are almost “free floating.” They’re not liquid, but they can move around. (This is very layman’s terms.) That’s austenite.

What causes distortion is when you’re cooling from austenite down to the point where that thing is, kind of, locked in; that can cause distortion in there because the molecules are still free to move. Some areas cool faster than others, and when you have that, you can get twists and turns or bulges. Once it gets down to the martensite temperature, that’s when things are, locked in. Is that fair?

Michael Mouilleseaux: The other thing that happens is you’re going from a cubic structure to a tetragonal structure. You’re asking, “Why are we there?” That’s where the expansion comes. The close-packed tetragonal structure takes up more volume than the austenitic or cubic structure. That’s where the volumetric expansion takes place.

Doug Glenn: At a higher temperature, the molecules are arranged in such a way that they take up more space; there’s more space between them.

In the cooling process with marquenching, if you bring it down just to the point where it’s, what Mike referred to as, the ‘martensite start temperature,’ that’s the temperature where things are just locking in. But it’s not so drastic that you’re dropping way down in temperature so that there are larger temperature differentials and things are really starting to get torqued out of contortion because of the difference in the cooling rates in the part.

Michael Mouilleseaux: The other part of that is that the formation of martensite is not time dependent. It’s not like you would have to hold it at 400 degrees for a longer period of time than you would at 200 degrees to get martensite. At 400 degrees, you’ve got some percentage of transformation. Say, it’s 30%. The transformation is temperature dependent. Because it’s temperature dependent, you can take it out and slow down the cooling rate. Then, as the transformation takes place, there is less stress, and if there’s less stress, then there is less distortion.

Again, it’s typically going to be distortion-sensitive parts.

The simplest geometric shape is a sphere. There aren’t any changes in section size in a sphere. It can be rotated, and you’ve got the same section size. You don’t have the kind of thing where one area is cooling more rapidly than another.

A major source of distortion is varying mass. Like a hole in a block: one portion of the block is two inches wide, and another portion is an inch wide. To think that that hole is going to stay straight all by itself, that won’t happen because there’s more mass around one end. By marquenching it and slowing down the transformation, you’re giving yourself an opportunity to reduce the amount of stress that’s generated. It’s the volumetric expansion in the thicker section than in the thinner section. Your opportunity to maintain that hole so that it stays round and it stays straight is much better. Otherwise, the thin section is going to completely transform before the thicker section does.

Doug Glenn: Transform to martensite or whatever, yes.

Michael Mouilleseaux: The extreme case in that is if that happens rapidly enough, and there’s a large enough differential in section size, the part cracks.

Doug Glenn: That’s the nightmare for the heat treater.

Bethany Leone: Are there any instances where it’s definite that another way to manage distortion would be better than marquenching?

Michael Mouilleseaux: Sure. Again, what’s currently sexy in this industry is gas quenching things. I’m going to say that cylindrical parts that have a thin wall, when properly gas quenched, will give you better distortion control, better size control than it would if you’d quench them in a liquid medium such as oil. We don’t want to forget that marquenching can be performed in salt, as well.

If we were going to talk about a fourth one, it might be salt quenching because that’s one of those things that’s not commonly utilized. There is some real opportunity with it.

Doug Glenn: Mike, thanks for ‘dumbing this down’ for us. We appreciate it! It’s sometimes a struggle to state things simply, but you did a great job.

Are there any closing thoughts you’d like to leave with us regarding the nearly-forgotten, popular heat treat processes, or anything else?

Michael Mouilleseaux: How about the combination of all three that I just spoke about?

Doug Glenn: Okay. Well, how about that?

Michael Mouilleseaux: I’ve got a distortion sensitive gear, and we’ve figured out that there is some stress in the part as a result of the final machining operation. We stress relieve the part, we carburize it conventionally, and then we marquench it. Those gears that I spoke about where we’ve got 20 or 30 microns of ID bore distortion — that’s exactly what’s done there.

Doug Glenn: Okay. Stress relieve first, conventional carburize, and then marquench. A combination of three.

Mike, thank you very much. This has been really helpful and it’s been good to learn a little bit on our Lunch & Learn. We’ll hope to have you back sometime to make other things understandable for us.

About the expert: Michael Mouilleseaux is general manager at Erie Steel LTD. Mike has been at Erie Steel in Toledo, OH since 2006 with previous metallurgical experience at New Process Gear in Syracuse, NY and as the Director of Technology in Marketing at FPM Heat Treating LLC in Elk Grove, IL. Having graduated from the University of Michigan with a degree in Metallurgical Engineering, Mike has proved his expertise in the field of heat treat, co-presenting at the 2019 Heat Treat show and currently serving on the Board of Trustees at the Metal Treating Institute.

Contact: mmouilleseaux@erie.com

Doug Glenn

Publisher

Heat Treat Today

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio .

Search heat treat equipment and service providers on Heat Treat Buyers Guide.com

Heat Treat Radio #88: Lunch & Learn — 3 Most Underrated Processes Read More »