![]() Stress relieving tips from Heat Treat Today? It's not what you think! In this Technical Tuesday, we'll be sharing some fast facts you need to know about stress relieving. It may not be as relaxing as some guided meditation, but at least you will walk away with a refreshed knowledge of stress relieving, a new technology for measuring material stress, and a video demonstration of the stress/strain curve.

Stress relieving tips from Heat Treat Today? It's not what you think! In this Technical Tuesday, we'll be sharing some fast facts you need to know about stress relieving. It may not be as relaxing as some guided meditation, but at least you will walk away with a refreshed knowledge of stress relieving, a new technology for measuring material stress, and a video demonstration of the stress/strain curve.

Stress Relieving Fast Facts

- What is stress relieving? In the most basic sense, stress relieving is heating a metal to a relatively low

Dan Herring

"The Heat Treat Doctor"

The HERRING GROUP, Inc.temperature and then slowly cooling it to reduce the affect of manufacturing-induced stresses.

- Why do heat treated parts need to be stress relieved? Manufacturing processes (forging, shearing, bending, etc.) introduce internal stresses, and these stresses, if left unaddressed, can cause the finished part to fail in its end application.

- Thermal stress relieving is the preferred method of stress relieving, but mechanical stress relieving is also an option. Vibratory stress relieving and shot peening are two mechanical stress relieving methods available to heat treaters.

Want more fast facts? Check out Dan Herring, The Heat Treat Doctor's®, Atmosphere Heat Treatment, Volume 1.

Addressing Stresses: Indentation Plastometry

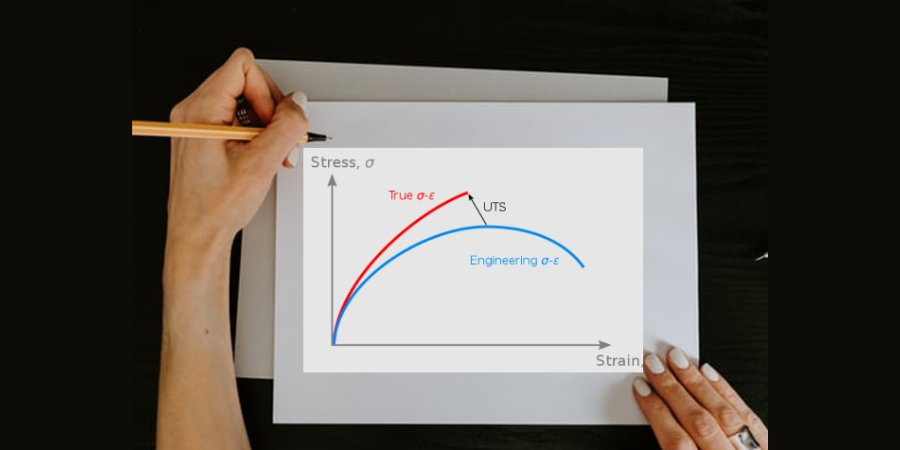

Stresses introduced during the heat treating process must be addressed. Failing to address these stresses can be disastrous. Mechanical testing systems are crucial in ensuring heat treating had its desired effect and that no new stresses have been introduced to the material. As most heat treaters know, the stress/strain curve of materials is often a give and take. To get high strength, you often have to give up ductility. Measuring the extent of these trade-offs — and measuring plasticity and strength characteristics in general — after heat treating can be time consuming.

In this episode of Heat Treat Radio, James Dean of Plastometrex explains a new technology, indentation plastometry, that measures microscopic stresses in heat treated material. These stresses can affect the yield point of a material and the point of plastic deformation. What's even better is that, with indentation plastometry, heat treaters can view stress/strain curves in minutes and know if there is a need for further stress relieving.

A Refresher on the Stress/Strain Curve

Need a refresher on the stress/strain curve after hearing from James Dean? Check out this episode of Heat Treat TV.

The stress/strain curve is "metallurgy basics." If you spend any amount of time in the heat treating world, this graph will be a familiar sight to you. Basic though it may be, a refresher it always a good idea. Just how much stress can a material withstand before breaking? How does heat treating affect the yield point of different materials?

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com