Energizing the Future of Furnaces — 4 Perspectives

What will the future run on? With growing discontent around current energy sources like natural gas and other fossil fuels, power sources for furnace equipment are due for a makeover. In this article written by Heat Treat Today and media partner Furnaces International, learn from heat treat and energy insiders around the world as they consider current technology investments and future energy opportunities that in-house heat treaters should consider when energizing the future of furnaces.

The four perspectives were written in response to the following questions: 1. What are the short-term and long-term investments for sustainable energy for heat treat furnaces? 2. What role does data and digitalization have in efforts to decarbonize heat treat furnace operations? 3. What other steps can be taken now in heat treat operations to decarbonize heat treat furnaces? 4. What challenges need to be overcome for (North American/European) heat treaters to leverage sustainable technology in furnaces?

This Technical Tuesday article comes from Heat Treat Today’s May 2023 Focus on Sustainable Heat Treat Technologies print edition. If you have any thoughts of your own about furnaces and sustainability, our editors would be interested in sharing them online at www.heattreattoday.com, email Bethany Leone at bethany@heattreattoday.com with your ideas!

1. Wise Heat Treat Decisions for Sustainable Solutions

“Don’t let the perfect be the enemy of the good,” is an excellent principle to follow when heat treaters look at making their operations more sustainable. Particularly when it comes to investments, the first step to reducing carbon output from heat treat equipment should always be to put in place a proper combustion maintenance system. I’ve never seen an investment that did not generate a savings that eclipsed the cost, well within one year. And this not only saves money, it also prolongs equipment life. It’s an all-around good thing to do from any angle.

Another area that heat treaters can improve is efficiently scheduling furnace up-time. All too often, I visit facilities where equipment that is not doing any work remains at operating temperature for a long time, because operators do not know precisely when to introduce more work into the furnace. If possible, idling the furnace at a much lower temperature would save a lot of money.

Programs and scheduling are the low-hanging fruit. Not taking care of them first would be like putting new carpet in the basement before you fix the leak. It’s always best to take care of the fundamentals and make sure you’re doing the best you can with what you’ve got before you go ahead and make those other investments.

In the near term, capital investments are a bit more tricky. There are certainly technologies that will improve efficiency with greater capital investment. These include recuperation or other methods of enhancing heat transfer. For radiant tubes, it could be inserts. The other elements could be pulse firing, particularly in instances where we’re trying to induce an increased rate of heat transfer by creating more mixing within the furnace chamber. These are “on-the-shelf” methods, though they have much longer payback periods, on average.

Switching equipment from gas to electric — or something drastic like that — may not be the answer. We have to focus on the incremental improvement. If I have an investment of 3 trillion dollars to make, it would be wise to first put it towards improving the efficiency of the existing equipment. That one change means fewer tons of CO2 emitted by the end of the year.

Speaking generally, evolutionary technologies must be developed. We have to pursue R&D aggressively, but let’s target the ultimate goal: reduce tonnage of CO2 emitted. That’s the goal. Let’s not confuse the technology or the tool with the ultimate goal.

“If I have an investment of 3 trillion dollars to make, it would be wise to first put it towards improving the efficiency of the existing equipment. That one change means fewer tons of CO2 emitted by the end of the year.”

John Clarke

Source: Pixabay/Geralt

Digitalization Empowers Investments

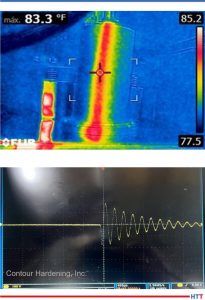

Digitalization, especially the improvement in data acquisition and analysis, is huge. With higher computational capacity on the controllers on a per furnace basis, we have the ability to start executing real-time analysis on the furnace and potentially implement a thermodynamic model of the furnace and how it’s operating. If I track measurements of total fuel flow, exhaust temperature, and time using the computational powers of a modern PLCs, for example, I can know the core temperature of the piece and exactly when I should pull the piece. That’s digitalization.

The other thing we need to keep in mind is the ability to upload data for analysis. In a sense, this is “the internet of things” (IoT). Let’s say I’m producing 100 tons of steel through a furnace per day. If I monitor the amount of natural gas that system consumes, I know that I have an energy intensity of X cubic feet of natural gas per ton of steel produced. If there’s a deviation, for whatever reason, I know to investigate. It could be the burners are out of tune, it could be something changed in the process, it could be a thermocouple is bad. So, there are a myriad of potential problems that could arise and, if I’m pulling that data, I can know that before I otherwise would.

This modern tendency of collecting and analyzing data is an incredibly powerful tool that should be encouraged and pushed forward. This is an example of the good and not the perfect; we’re trying to take the existing systems and make them more functional and effective.

Digitalization should also be considered holistically — energy is just one part of it, granted a large and expensive part. But it is worth noting that digitalization helps efforts to create safer operations by making systems more consistent.

Next Steps Require a Step Back

As a consultant, I often disrupt facilities, force people to stop thinking about day-to-day activities, and challenge them to think anew about some of these systems. Never underestimate the importance of thinking — and thinking slowly. And thinking requires quiet, but it also requires collaboration, and it requires the plant manager to actually engage with the line operators. Often, we have silos of knowledge — we have maintenance, we have operations, we have management — and they don’t communicate.

Second, in stepping back, make a plan. Prepare the planning process for facility transitions.

Finally, we may always take a step back and ask if a material change to eliminate a heat processing step can be made. In some cases, eliminating the heat processing step entirely will have a big financial impact. Perhaps there are performance specifications that can be met with microalloyed steels that don’t require heat treating! In these cases, be aware that incoming steel costs do not chew up savings.

Source: Pixabay/Martinelle

From a decarbonization point of view, you would need to look at the overall supply chain carbonization and intensity of the mining of these more exotic materials. Depending on the supply chain carbon output of the new material, eliminating heat treating could be a plus on CO2 emissions, though perhaps not a total cost savings.

Challenges Are from Within: Interest Rates and Internal Investment

In North America, rising interest rates mean that we are somewhat in a catch-22. When interest rates are low, investments into changing equity or the treasury level of the companies typically occur versus investing in the core business. Now that interest rates are higher, companies actually may start looking at optimizing the actual performance of their individual company. But too many people are too aggressively pursuing figures, caring more about the return on equity versus focusing on the core performance of the operations. Enterprise is often given a capital budget of X when, in reality, the capital budget really should be based on a two-year hurdle rate. Management wants to invest in the enterprise on all projects that will return 30% on internal investments because they see large corporations making major investments and other businesses are lucky to earn half that kind of return

One of the impediments is simply convincing management and decisionmakers on the validity of internal investment. Your enterprise represents an internal investment opportunity that exceeds the return you’re likely to receive from an acquisition of a new enterprise. I know that runs counter to some of the thinking prevalent in the market today, but it is important to point out. I am an “internal return on investment” kind of guy, so I speak with a bias. But time and time again, I see opportunities go unexecuted because they don’t meet a preconceived budget. If your objective is to make money, invest it to maximize the return.

Our national laboratories and our universities throw out a lot of great technology. Some of it is ready for primetime, some is in the nascent of condition and needs more investment and time to mature. I’m not sure we have enough enterprises to partner with these design and research groups and commercialize the ideas. It’s in this “valley of death” — where the basic technology has been developed and proven to be viable, but the commercialization and the manufacturing is lacking — that we need to overcome and increase enterprise. Particularly in the heat treating industry, there is a problem of fewer “catchers” who will partner with and develop new technologies that could aid in decarbonization. This is because there have been a lot of acquisitions. If you look at the membership of IHEA, it’s the same people and the same businesses but there are fewer people. Everyone is buying everybody else. Larger corporations tend to be less likely to take the risk on a piece of technology that won’t immediately pay back. They also have a lot of “not-invented-here” issues as well.

One solution is for the Department of Energy to invest. Though they already do this, even greater investments into brokers and advocates are necessary to pick up this technology and pass it through instead of simply trying to contact people. During U.S. President G.W. Bush’s time, the Department of Energy had a “Save Energy Now” program during a natural gas spike. The program sent people, like myself, around to plants to run analyses for free. The program was extremely valuable because it gave enterprises motivation. I did speeches at many different automotive plants and participated in collaborative events as part of that program. I think refunding that program and refocusing on something like that would be beneficial.

My idea of the way forward is half technical and half promotional, demonstrating to people that there is another way. That is an effective role for government. I would like to see them redo that. It would be a different emphasis.

About the author: John Clarke is the technical director and owner of Helios Electric Corporation, a company based in Fort Wayne, Indiana, that specializes in energy and combustion technologies. The depths of his knowledge on energy and combustion topics can be seen in the technical articles and columns that John has contributed to Heat Treat Today's Combustion Corner.

For more information: Contact John at jclarke@helios-corp.com.

2. Energizing Our Evolving Industry: Past, Present, Future

Yesterday’s Attempts at Energy Efficiency

For the industrial context where the improvement of productivity, energy efficiency, and environmental performance is increasingly essential — especially for temperature furnaces — the coupling between the hybridization of furnaces integrating different technologies becomes a solution to be seriously taken into account.

During the last century, with the appearance of energy and emission constraints, the steel and glass industries used for the most part the same energy saving techniques with heat recovery on flue gases for preheating combustion air, thus reducing energy consumption by 20%–30%. In the 1980s, regenerative burners arrived. Based on the same principle of preheating air — though at higher levels — regenerative burners improved the energy efficiency of the installation, but also increased NOx emissions. This is clear for many large industrial companies in steel, glass, and cement, for whom the industrial electric furnaces reduce emissions and risks, and require little maintenance. But the electrification of existing furnaces, which often run on gas, is far from obvious as fired furnaces are still numerous all over the world.

Today’s Solutions: Which Is the Way Forward, Gas or Electric?

Today, what can be done to improve energy efficiency? Improving energy efficiency in glass or steel reheat furnaces can be achieved by implementing various strategies. The approach for short term investments needs to be pragmatic. It is possible to implement better practices and technologies on any furnace.

We can point to some general short-term steps that can help improve energy efficiency:

- Conduct an energy audit

- Insulate the furnace

- Upgrade insulation

- Install energy-efficient motors and drives

- Implement energy management systems

- Optimize combustion

- Use waste heat recovery systems

- Upgrade to more efficient equipment

- Use advanced process control systems

By implementing these strategies, it is possible to significantly reduce energy consumption and improve the energy efficiency and emission of a fired glass furnace. However, it is important to note that the specific strategies used will depend on the furnace’s operating conditions.

When heat treaters step back from burner-focused solutions and short-term plans, the next question is often: Do we need to change or upgrade our equipment? And is electric the only wise way to go when seeking energy efficiency?

The choice between gas and electric furnaces depends on a variety of factors, and there is no one-size-fits-all solution. It is important to consider the specific needs of the application and weigh the costs, energy efficiency, and environmental impact when making a decision. One might consider the following:

- Gas furnaces are generally less expensive to purchase and install than electric furnaces. However, the cost of operating a gas furnace can be higher due to the fluctuating price of natural gas. Electric furnaces, generally more expensive to purchase and install, typically have more stable operating costs.

- All the relevant references of use of electrical furnaces in the past were related to lack of flexibility especially in glass when changing the quality and types of glass or colors. This could cause some issues where flexibility is needed for production operations.

- Considering the environmental impact, gas furnaces produce carbon dioxide (CO2), and other greenhouse gases that contribute to climate change. Electric furnaces do not produce direct emissions, but their indirect emissions depend on the source of the electricity used to power them. If the electricity is generated from renewable sources such as wind or solar power, then electric furnaces can be more environmentally friendly.

Tomorrow’s Possibilities: Looking Beyond the Short-Term

In order to move into the future, education about the present is key. Focusing on environmental impact looks different regionally, and the lack of awareness and education of local teams needs to be considered as well. Regulations and standards related to emissions and energy efficiency could be regulatory barriers: What is true in China or India is not necessarily fit for Continental Europe, the U.K., or U.S.

From region to region, the compliance with these regulations can be a significant challenge for heat treaters. Meeting these requirements may require significant investments in new technology or modifications to existing systems where electric furnaces are direct impact on the direct emissions.

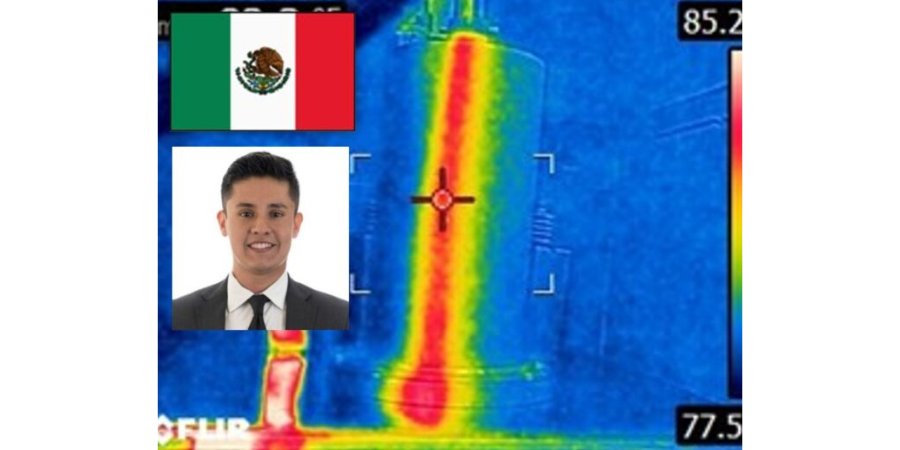

Many heat treaters or glass manufacturers may not be aware of the benefits of sustainable technologies or may not fully understand how to implement them. Providing education and training sessions on sustainable technologies can help overcome this challenge. Data and digitalization play a critical role in efforts to decarbonize heat treat furnace operations. Here are some ways in which data and digitalization can contribute to decarbonization:

- Resistance to change

- Real-time monitoring

- Predictive maintenance

- Optimization of energy consumption

- Supply chain optimization

- Carbon accounting

Investing in renewable energy sources such as solar or wind power can provide long-term energy savings and reduce greenhouse gases, but for most heat treaters, these are monumental decisions. The approach to long terms investments needs to be pragmatic focusing on renewable energy sources when available near the plants where a power grid is available.

Any end-users can work with experts in sustainable technology to identify opportunities and develop strategies for implementation of Industry 4.0 technology using SCADA systems and predictive tools. It may also be helpful to collaborate with other companies or industry groups to share best practices and insights. Government incentives or funding programs may be available to help off set the costs of implementing sustainable technologies.

“Investing in renewable energy sources such as solar or wind power can provide long-term energy savings and reduce greenhouse gases, but for most heat treaters, these are monumental decisions. The approach to long terms investments needs to be pragmatic focusing on renewable energy sources when available near the plants where a power grid is available.”

Philippe Kerbois

Source: Manny Becerra

In conclusion, data and digitalization are critical tools in efforts to decarbonize heat treat furnace operations. By providing real-time monitoring, predictive maintenance, energy optimization, supply chain optimization, and carbon accounting, data and digitalization can help heat treaters to reduce their carbon footprint and transition towards more sustainable operations, including electric furnaces.

About the author: Philippe Kerbois, previously Regional Sales Manager EMEA – Glass for AMETEK Land, has over 20 years’ experience in high value, complex technical solution sales with specialties in glass, renewable energies, automotive, water filtration, energy production, gas turbines, automation, building automation and oil and gas. He holds a degree in mechanical engineering (Diploma of Higher education) associated to ESTACA degree (Aeronautics and Automotive Engineering school).

For more information: Visit www.ametek-land.com.

3. Investing in Efficiency

A Low Carbon Future Could Be One Investment Cycle Away

It is helpful to put some numbers around sustainability. Recent reports from the IEA (International Energy Agency) indicate we need to improve energy intensity by around 4% between now and 2030 and about 3% from 2030 to 2050 to be close to achieving net zero goals. The 4% level is double what was achieved over the last decade.

Sustainable investments in heavy industry (steel, cement, chemical) have already started. Blast furnaces and cement kilns last for around 40 years, and 2050 as a net zero target is now less than one investment cycle away. North America is leading the way by investing in electrifying the industry via electric-arc furnaces which aid in cleaning up an industry that has had a high dependency on coal. Newer technologies, including the electrolysis of steel, promise alternative ways of low-carbon manufacturing, but this technology will only likely provide significant production quantities after 2030.

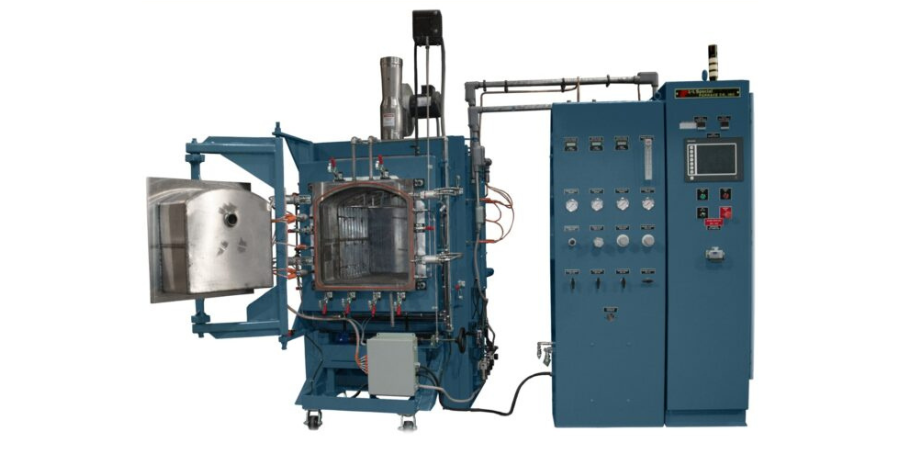

At the lighter end of the industry, industrial furnaces for heat treatment may generally have a slightly shorter lifecycle. Still, investment decisions in new capital equipment today will directly impact the industry’s emission profile over the next 30 years. Therefore, this long-term investment needs to consider the potentially changing energy landscape.

At face value, in many places in the U.S. and Europe, the ratio between gas and electric pricing would steer investment towards gas-fired furnaces if the only criteria were running costs (ignoring heat treat equipment that is only electric-fired, e.g., vacuum furnaces). This cost advantage is starting to change with increasing carbon taxes, potential disruption of fuel supply (currently in Europe), further stringent NOx emission requirements and continued supply challenges for complex gas trains.

Combustion burner design can significantly impact the energy efficiency of a furnace. Straight-through tubes are on the scrap heap, and recuperative and even regenerative burner systems now aid efficient energy use. In addition, dual-fuel burners that can work on hydrogen or natural gas are becoming available. Although the economics of carbon-free hydrogen remains a constraint to its heavy use, this is expected to change over time, with innovations to improve the hydrogen landscape post-2030.

There is a significant amount of research in next-generation elements for electric furnaces. The element material composition, desired life, and manufacturability are all areas currently being explored. In addition, the controllability of an electrical element is significantly better than its combustion alternative, and unique algorithms are in development to take advantage of this to aid efficient processing.

More Digitalization, Greater Efficiency

Today, heat treat operations lack visibility and access to critical process data, leaving operators reactive when mitigating performance factors such as utilization time, quality, yield, and energy consumption. Data and digitalization provide many opportunities to improve efficiency and reduce overall energy consumption within furnace operations. Poor thermal uniformity can lead to scrap and rework of material, which both result in excess energy consumption.

Process drift can also cause more energy to be consumed over time to achieve the same operational results. Examples of process drift include drift from target program set points, processing times, nominal values such as desired heater power output and thermal uniformity values. Lack of visibility to process drift can create rework when specifications are missed the first time or potentially result in a scrapped batch.

“Through proper data collection and analytics combined with thermal systems expertise, problems can be overcome, which not only reduce carbon emissions but also improve productivity and profitability for heat treaters.”

Source: Adobe Stock/panuwat

It is important to recognize that data can be a powerful input for decision making to improve process efficiency. However, data alone is not enough to act to create significant improvement. To utilize data for process improvements, it must be delivered in a way that is easily consumed and creates clear action to be taken. Thus, it is important that we combine data with subject matter expertise to contextualize and transform data into actionable insights. For example, Watlow and Eurotherm have combined their expertise to enable value creation in collecting, interpreting, and transforming data into actionable insights that can be put in the hands of the operators when they need it, where they need it.

Through proper data collection and analytics combined with thermal systems expertise, problems can be overcome, which not only reduce carbon emissions but also improve productivity and profitability for heat treaters.

Steps Towards Digitalization

A heat treater’s first step towards digitalization should be to work with suppliers to understand what digital solutions are being offered. Watlow and Eurotherm have pooled their skills to find ways to offer better solutions. Driving towards data-driven decisions impacting process performance and energy consumption is relatively simple and gives operators an opportunity to take proactive measures, and it also lays the foundation for future investment through data-driven performance trade-offs and insights.

At a thermal-loop level, find suppliers that are focused on improving the performance of electric-fired furnaces from the transformer to the element to the power controller and process controller/recorder.

Consult your supplier about recording strategies and leveraging power data. First, record data in a format that doesn’t create data islands but protects the integrity of the raw data. And second, leveraging power data in real-time allows you to share information between furnace zones or different furnace equipment, which can help lower peak-power demands by scheduling when the individual SCR power controllers fire.

Recently, we launched a new 14.0 pilot service program which provides data insights to enable peak performance. Tracking process performance through insightful data, correlations related to process inefficiencies can be established. Energy consumption improvements to the process can be made such as identifying and mitigating inefficient combustions.

Consider the Cost

Top of the list of challenges to adopting sustainable technologies is the ongoing cost conversation — the cost of gas versus electricity. The gas and electric prices do differ significantly across all regions. However, this equation is changing in even the most attractive gas districts. Once you add on rising compliance costs to emissions plus the ramp of renewables, this will ultimately favor an electric future.

In the U.S. and most parts of Europe, energy has been plentiful and reliable for a long time. The U.S. has also enjoyed decades of relatively low costs of all forms of energy. Contrast this with some regions of Asia where weekly and sometimes daily power interruptions still occur. As a result, there is a different mentality and behavior around resource use and abuse.

The higher price of energy in Europe, and the current spike in the Ukraine conflict, have started to impact behaviors. For example, we now see customers with a mid cycle refurbishment of a furnace looking to evaluate a move from gas to electric.

About the authors: Peter Sherwin is a global business development manager who is passionate about offering best-in-class solutions to the heat treatment industry. He is a chartered engineer and a recognized expert in heat treatment control and data solutions. He has lived and worked in the U.K., India and the U.S.

Miranda Pizzella holds a Ph.D. in aerospace engineering with a concentration in thermal-fluid science from Parks College, Saint Louis University. Miranda is leading the company’s Industry 4.0 strategy and has accelerated the adoption of related technologies to transform the business through leveraging data to create more value. Miranda currently leads the computational engineering team and the Industry 4.0 development team.

Andy Selvy holds a B.S. in ceramic engineering from Missouri University of Science and Technology and an MBA from Maryville University. In his current role as a chief system designer, he leverages 20 years of solving complex thermal system problems to help grow new technology into scalable products and services.

For more information: Contact Peter Sherwin at peter.sherwin@watlow.com or visit these helpful links: https://www.iea.org/reports/net-zero-by-2050,

https://www.energy.gov/eere/analysis/energy-efficiency-vs-energy-intensity, and www.watlow.com.

4. A Hybrid Future

A Middle Way: Hydrogen in Combination with Fossil Fuels

There are a number of things to be taken into consideration for “energizing the future of glass furnaces.”

In the short-term, it is possible to add electric boost to an operating furnace on-the-run, to reduce the amount of fossil fuel being used. However, the proportion of electrical energy that can be installed, relative to the amount of gas currently being used, makes a very small difference to the CO2 emissions. The reason being that approximately 30% of the total energy is used for “holding heat,” i.e. to keep the structure warm. A fair part of this holding heat is required in the regenerators which pre-heat the air and although 1 kW of electricity should save 2 kW of fossil fuel, in reality with regenerative furnaces it is difficult to get close to this figure. Anything from 1.3-1.8kW is the norm.

The next stage, which is a small incremental investment, is to go to superboost. Superboost, again, is not very effective unless the amount of air and gas going through the regenerators can be reduced, which is nigh on impossible on end-port furnaces and difficult on cross-fired furnaces. Therefore, the other option is to add hydrogen to the natural gas stream and this can only be done by Government edict. But it is relatively easy to do with the existing burner set up, however, this is only feasible up to a maximum of 30% with current technology, before major technical issues are encountered. There are particular capital requirements needed for handling large amounts of hydrogen.

Less Fossil Fuels, More Hydrogen and Electrification

The proper progress for glass furnaces is to convert from fossil fuel, air/gas, regenerative furnaces to oxy-fired. This will give an improvement in thermal efficiency which will have a small impact on CO2 emissions but not significantly. The only way long term to have a major impact is either hydrogen firing or all-electric. In both cases a considerable amount of investment is required. However, the opinion of the author is that hydrogen will be a premium fuel and the only fuel in many industries and therefore if alternatives are available for the glass industry these will more likely to be adopted.

Source: POLEX/Adobe Stock

The issues regarding the safety of using hydrogen presents huge difficulties in terms of mitigating risk. We must also consider that burning hydrogen increases the level of foam in a glass furnace, which is detrimental to melting efficiency a the refining of glass. Whilst these two factors may be overcome, there is the final issue that currently, no refractories exist that can withstand the product of combustion of a hydrogen flame, which is superheated water, possibly at 2400°C (4352°F). This is a major problem for the industry to overcome.

For this reason the author believes that a hybrid furnace with 80% of the melting energy from electric and 20% from some kind of top heat, could be electric heating, or could be hydrogen flame or some other alternative fuel, is the answer. The issue with going all-electric is that a massive investment is needed in the grid reticulation system as well as finding sources to generate green electricity to cover the requirements. This is a major issue for the Government to address as many other industries will need to electrify as well.

The major challenges for hydrogen are as enunciated above. In particular, the safety issue of hydrogen is a huge change, the other issue is that 3 times the volume of hydrogen is required than that of natural gas meaning reticulation systems will have to be changed. And finally, in container forehearths where air/gas mixtures are used for conditioning the glass, this is not possible with hydrogen and so the only way to decarbonize this process is to go all-electric. This technology is currently available and already shows anything between 80-90% both energy reduction and cost reduction. As I stated before, the only other major challenge is the amount of electricity available for industry and the public at large, in order to make these changes.

Short-Term Digitalization Efforts, Investments, and Impact

Big data and digitalization can assist decarbonization efforts, but this requires no more than what is currently available for fossil fuel fired furnaces. Capital investment is low, and the technology is available now.

About the author: Stuart Hakes has 58 years in the glass industry. He studied Glass Technology in England and worked in the United Kingdom with container plants affiliated to the O-I Group. Stuart joined F.I.C. (UK) Limited as CEO in 1999 and has been there ever since.

For more information: Visit www.fic-uk.com.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Energizing the Future of Furnaces — 4 Perspectives Read More »

Sasha Tupalo, the manager of Thermatool Labs at Thermatool Corp., was recognized in 2019 as a 40 Under 40 rising star, and she has more than lived up to this award; she answers the call of leadership through educating others and managing a variety of projects. In this

Sasha Tupalo, the manager of Thermatool Labs at Thermatool Corp., was recognized in 2019 as a 40 Under 40 rising star, and she has more than lived up to this award; she answers the call of leadership through educating others and managing a variety of projects. In this