Heat Exchanger Manufacturer Anticipates New EV/CAB Line

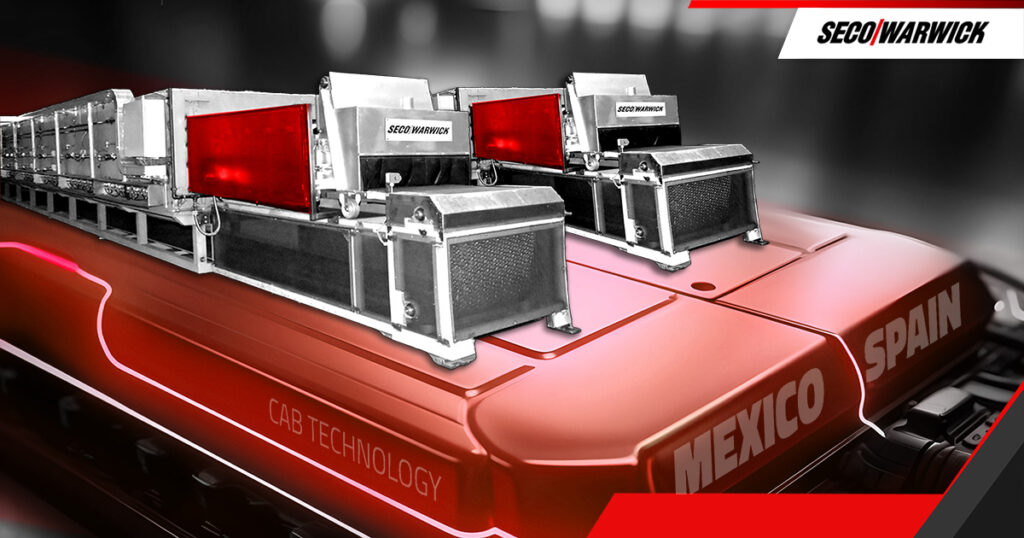

An international manufacturer of heat exchangers is expecting a new EV/CAB line to support their production of components, subsystems, and system solutions for thermal management in cars. The company provides energy-saving and high-performance products for regular petroleum and diesel fueled cars, as well as solutions for new electric vehicles.

Vice President of Aluminum and CAB Products Segment

SECOWARWICK

Source: LinkedIn

“The EV/CAB line on order is designed specifically for the production of “Snake” type battery coolers,” said Piotr Skarbiński, VP of the Aluminum Process and CAB Business Segment in SECO/WARWICK. He further commented that the heating and cooling design “contributes to the final product’s exceptional quality using our unique technology that achieves excellent temperature uniformity across the width of the belt, which is the key to successful production.”

The company will execute their first “Snake” battery coolers in SECO/WARWICK furnaces. This is the eighth CAB line which will operate in this automotive industry manufacturer’s plants and the second one with a width of 2,300 mm.

The controlled atmosphere brazing (CAB) line on order will include a convection preheating chamber, a radiation furnace and two cooling chambers. The entire system will be equipped with a dedicated control system.

“This cooperation opens new perspectives for the SECO/WARWICK Group development in our region. The excellent heating and cooling design contributes to perfect temperature uniformity across the 2300 mm belt width, which is the key to successful production. We have already sold over 20 such solutions in China, and the demand for them is constantly growing,” commented Liu Yedong, Managing Director of SECO/WARWICK China.

Around the world, the demand for battery coolers is increasing due to the increasing production of electric vehicles.

Find Heat Treating Products And Services When You Search On Heat Treat Buyers Guide.Com

Heat Exchanger Manufacturer Anticipates New EV/CAB Line Read More »