Bundle Up for Fall with 4 Vacuum Heat Treat Articles

![]() Getting excited for the November print edition? In 2021, Heat Treat Today released the inaugural Vacuum Heat Treating print edition. This edition is set to release every November to help heat treaters better work their vacuum furnaces and vacuum heat treat processes.

Getting excited for the November print edition? In 2021, Heat Treat Today released the inaugural Vacuum Heat Treating print edition. This edition is set to release every November to help heat treaters better work their vacuum furnaces and vacuum heat treat processes.

This Technical Tuesday original content round-up shares the hottest vacuum heat treating articles from this past year as you bundle up for the cool weather this fall. Enjoy!

Graphite in Vacuum Furnace Fixturing

Let's talk about carbon/carbon composite --- C/C.

Why is the vacuum furnace industry excited about its use in graphite vacuum furnace fixtures, grids, and leveling components? Because it can be readily machined for special shapes and applications. The lighter-weight material is mostly composed of carbon fibers and a carbon matrix (or binder).

As the authors of this article explain, "They are among the strongest and lightest high temperature engineered materials in the world compared to other materials such as basic graphite, ceramics, metal, or plastic. C/C composites are lightweight, strong, and can withstand temperatures of over 3632°F (2000°C) without any loss in performance." Intrigued, are you not?

Read the article by Solar Atmosphere's Roger Jones and Real J. Fradette, "The Use of Graphite for Vacuum Furnace Fixturing."

Step-by-Step Guide To Choose Heat Treating Equipment (English / Español)

If it's time to choose an industrial furnace, let's break it down step by step:

Step One: Quote Request

Step Two: Supplier Selection

Step Three: Study and Evaluation of Offers

Step Four: The Price

Follow this guide and avoid saying things like "The substation and/or the cooling tower did not have the capacity"; "The equipment is not what we expected"; or “They never told us that the furnace needed gas in those capabilities." If there are steps you take when selecting an industrial furnace, let us know in a Reader Feedback note here.

Read the article by Carrasco Hornos Industriales' Carlos Carrasco, "A Guide to Selecting Heat Treating Equipment" or "Guía para la Selección de Equipos para Tratamiento Térmico."

Pressure vs. Velocity and the Size of Your Furnace

If you like the R&D world of heat treat, but also like to be grounded in practical heat treat solutions, this is the article for you. Read about what this commercial heat treat found out about how size relates to the pressure and velocity of vacuum furnace cooling rates. Here are the facts you will learn:

- The greatest impact on the cooling performance in a vacuum furnace is to increase the___ ______ within ___ _____.

- This is achieved by ______ __ ______ of the ______ ____.

Read the article by Solar Atmosphere's Robert Hill and Gregory Scheuring, "Vacuum Gas Cooling: Pressure vs. Velocity, Part 1 of 2."

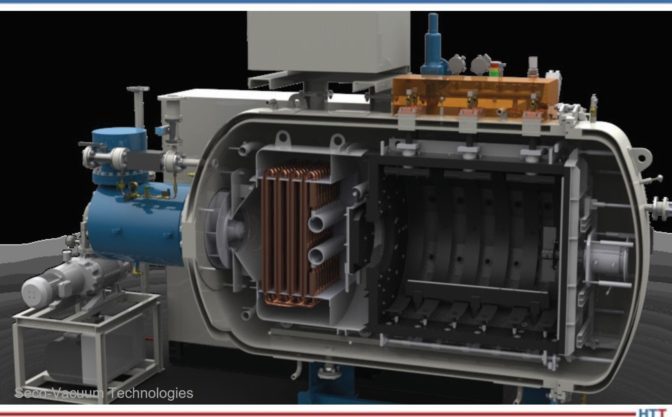

Energy at Large: A Heat Treat Vacuum Furnace Case Study

If you like to read about how heat treaters can be game changers in multinational science projects, this is the article for you. A specially designed vacuum heat treat furnace was commissioned to heat treat critical components in a large energy generator. The heat treating of these components takes 5 weeks to complete; talk about a long, uniform heat treat period.

If you like to read about how heat treaters can be game changers in multinational science projects, this is the article for you. A specially designed vacuum heat treat furnace was commissioned to heat treat critical components in a large energy generator. The heat treating of these components takes 5 weeks to complete; talk about a long, uniform heat treat period.

Read about the energy experiment, the heat treat furnace, and the heat treating process in this technical feature.

Read the article by SECO/VACUUM's Rafal Walczak, "Harnessing the Sun: A Heat Treat Case Study with General Atomics."

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Bundle Up for Fall with 4 Vacuum Heat Treat Articles Read More »