Heat Treat Radio #78: Heat Treat Legend Suresh Jhawar

Heat Treat Today publisher and Heat Treat Radio host, Doug Glenn, meets another Heat Treat Legend, Suresh Jhawar. In this third installment of the Heat Treat Legend series, you’ll hear how Suresh became the president of G-M Enterprises, what he believes are the key skills of leaders, and what words of advice he has for budding leaders.

Heat Treat Today publisher and Heat Treat Radio host, Doug Glenn, meets another Heat Treat Legend, Suresh Jhawar. In this third installment of the Heat Treat Legend series, you’ll hear how Suresh became the president of G-M Enterprises, what he believes are the key skills of leaders, and what words of advice he has for budding leaders.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

Doug Glenn (DG): Well, welcome everyone. This is Doug Glenn, once again, with Heat Treat Today speaking with the great honor of talking with another Heat Treat Legend. Today, we’re going to meet with Mr. Suresh Jhawar who was very instrumental in the founding of a vacuum heat treating company, and other experiences. I’ll let him tell some of that story. But, first off, Suresh, thank you so much, it’s really, really nice to have you with us.

Suresh Jhawar (SJ): Thank you and you are welcome.

DG: I want to have you spend a little bit of time telling people about some of your work background: Where did you start? How did you get in this industry? Where you went and what did you ended up doing?

SJ: I came to the United States in 1962 and attended Marquette University in Milwaukee. I graduated with Master of Science in mechanical engineering and an MBA in marketing. After that, in 1970, I started at Ipsen Industries as a senior project engineer for the vacuum furnaces. Within a year, I was promoted to the position of manager of engineering services. Soon after that, I was promoted to the director of heavy equipment division, handling large and complex projects.

Mr. Wesley Gable, who was a senior vice president of Ipsen Industries, inspired me and was really helpful in my career growth. He appreciated that I was hardworking and talented in performing well to challenges and did all that was possible for meeting difficult deadlines. When my car had a problem, he even loaned me his Cadillac to go back and forth to work.

So, that is, briefly, how I got into the vacuum furnace business.

DG: So that was with Ipsen. You started with Ipsen in roughly what year?

SJ: 1970, and I left them in 1982.

DG: Where was Ipsen at that time?

SJ: Rockford, Illinois and they are still.

DG: So, where after Ipsen did you go?

SJ: Well, I was very happy there. We had almost 400 people in Rockford and there were about 300 in Germany. I was doing good. There were two vice presidents and a president and then after that, I was part of that management team. I was in the top five people at Ipsen and driving the company in cost savings, improving products, and customer relations. I was very happy.

But I was contacted and recruited by Abar, and I was not interested. Still, I thought, “Let’s go and see.” I had close to five interviews with them, up to the chairman of [indiscernible] and they offered me the job. I always wanted a position where I could run the entire operation. Ipsen was also considering that kind of a growth for me, but they said that it would take three to five years, and I was not patient at all. When the Abar position came, it doubled my compensation. So, I took that challenge, and I ran to Abar.

My boss [at Abar], John Henry, when he stepped into my office, I said, “John, you guys screwed me.” He said, “What do you mean?” I said, “You know, I came from a nice company, and you have such a bad company here. But I’m very excited now because any idiot can improve upon this thing.”

DG: I’m sure you made him feel really good about that!

SJ: I was asked by John Henry, then the president of Abar, to write a justification. I was in Monterey in L.A., California, attending a management seminar on how to be an effective manager. They don’t let you get any phone calls, but there was an emergency and John Henry was calling. He said, “I met with Ipsen people. Can you write why it makes sense for Ipsen and Abar to join together?” In the night, (I had a nice room with a fireplace), I opened a wine bottle, and I wrote thirty pages in all caps, handwritten. The next morning, I overnighted that to John Henry and that is where it all started.

During the merger, John Henry — who was a Harvard MBA — was not happy where he was, so he was looking for jobs. I know he had resumes out, but he couldn’t find one. When this situation came, I was supposed to take over; when this opportunity [the merger] came, then I was the odd man.

DG: Ok, ok. You wrote the justification and then you got booted.

SJ: Yes. So, for a year and a half, I did a few projects. I worked in Germany, then I went with Sauder in Houston. Every weekend, I used to fly back and forth — I had an apartment. At Sauder, in less than a year, we sold three vacuum furnaces. But I was not happy. They were doing 5 million and losing a million dollars. It did not fit my objective.

Then, a customer, Continental Heat Treat, their president put me in contact with Keith Grier [founder of G-M Enterprises], so that’s how we met. In the beginning, I wanted $110,000/year; they offered me $55,000. Initially, I said no, and I went away. Later, when things did not go well at Sauder (or I didn’t like the company), Veena pushed me, and I took it. So, I came down and joined them and they said, “How much?” I said, “Your number.”

DG: I want to interject because I want to get a few names straight for people. You and I know who these people are, but others might not. First off you mentioned Keith Grier. Was Keith, at that time, one of the owners of GM? G-M existed at that time, yes?

SJ: Yes. And he had a partner, Mac McGuire.

DG: So, that’s the ‘G’ and the ‘M’ of G-M Enterprises. And you mentioned Veena, which you and I know who that is, you especially, but that’s your wife. You said Veena was pushing you to go ahead and take the job.

And you decided to take the position at GM?

SJ: Yes, as a partner with a 15% interest. Later, I bought McGuire out within a year. He was then out, so then Keith and I were the partners.

DG: What year was that?

SJ: 1987.

DG: So, in 1987, you entered in and basically started taking ownership, or took a portion of ownership, with GM.

SJ: You know, Keith was a nice guy and a good friend. He was very good with customers, and he was a good service tech. So, I helped in developing the product line. However, Keith wanted orders, and we could not make money, and we were kind of a break-even company. I was tired and so I went to Keith, and I said, “You buy me out.” He said, “No. I have a first right, you buy me out.” We talked and he wanted too much money which I could not afford. For six months, I dragged my feet, and I was losing interest. I went back and I said, “Okay, I accept.” In 2005, I took total ownership and changed the name from Greer Jhawar Industries to Jhawar Industries doing business as GM.

DG: Ah, okay! I had not heard that official business name.

That’s enough to let us know at least where you are. People should know right off that Suresh was the owner of G-M Enterprises; it is no longer owned by Suresh and is actually owned, now, by Nitrex.

I want to move on to the next question: In your years, as you were starting to either get involved with the industry or when you were in the industry, can you think of one or two people that had a significant impact on you, that maybe encouraged you in the industry?

SJ: Yes. One was Wesley Gable, who was a senior vice president [of Ipsen]; another the president of Ipsen, Les Senet, and then the next president (I’m trying to remember his name), he was very supportive of me — Lu Clay.

DG: And these guys all were just an encouragement to you in the sense of “Hey, get out there, and do it”, or how were they encouraging?

SJ: They liked the way I approached people, the business, customers, I was hardworking, meeting goals; so, I was number one choice for them.

DG: When you look back, Suresh, over your career, can you think, in your mind, what might have been the top two or three major accomplishments that you’ve done?

SJ: At Ipsen, I became, technically, the assistant to the president and traveled with him extensively to Poland and Armenia. Ten times I visited Poland in less than two years, every other month.

DG: Just curious, but why Poland? What was there?

SJ: The steel mill and annealing of silicon steel coils for the transformer steel. At Ipsen, we sold eight furnaces to Armco Steel in Middletown, Ohio. So, there was a large project of ten furnaces. Remember, at that time, Ipsen was doing only 12 or 13 million and that project was like a 6- or 7-million-dollar project.

The president and vice president were handling the commercial aspect, but before that, you have to convince the technical people that you have the right product and the right solution. That was my task. Ipsen was then successful in the booking the order for ten large car bottom furnaces. They were 84 inches wide x 45 inches high x 32 feet long. Furnaces were made in four sections, bolted. At the same time, Ipsen was also working on the license agreement with Elterma, which later became SECO/WARWICK. So, I was assisting the president and the vice president on the technical side of this license agreement and that was also signed.

I also brought Wessman Engineering from Kolkata, India, as a sales agent for Ipsen. Later, after I left, it became a joint venture and, eventually, Ipsen established a manufacturing base in India wholly owned by Ipsen. So, it was started with me by bringing Wessman Engineering into the position.

Under my leadership with a period of three years, Abar grew and had a very, very good profit, and that’s when Abar and Ipsen came to a merger.

DG: That’s interesting. To me, there are a couple of good things there. One is one of your major accomplishments was that merger between Abar and Ipsen, which was great. But you should mention the success you’ve had with G-M Enterprises, as well; that’s got to be one of your top accomplishments.

SJ: In 1987, I joined G-M as a minority partner. At that time, G-M Enterprises was doing about 1.8 million annually and was a break-even company. In 2005, I acquired total ownership of G-M and brought in Veena Jhawar as director of supply chain and the oversee man of the operation while I was concentrating on developing customer base and innovating state of the art vacuum furnaces with superior designs and construction.

By 2018, G-M became a leading supplier to GE all over the world from Singapore to Japan and to Brazil. Pratt Whitney, Rolls Royce, Bodycote France, Precision Castparts, PCC, U.S. Airforce, and DLA, to name a few.

I was also instrumental in developing the MIM furnace, and proud to say that I developed a strong relationship with the founder and the chairman of INDO-MIM. At that time, they had only five people in their group; today they have over 3500 people.

DG: What was the name of the company again?

SJ: INDO-MIM, Inc.

Then, about five years back, they established the U.S. division because it became that customers in the U.S. wanted U.S.-made things. So, they took the space from Kelly Airforce base in San Antonio — I don’t remember how many square feet it was, maybe a 40,000 square foot building — and ordered two furnaces for their U.S. plant. By then we had already put thirteen furnaces in India. Last year, G-M got orders for three more furnaces, and before I left and when I was working as a consultant, sold two furnaces and then wrote a multi-year contract and on that basis, they bought three more. So, they have well over twenty furnaces in India and about five furnaces in the U.S. These are good-sized. They are 36 x 30 x 84 inches long. In the MIM industry, I believe, these are the biggest furnaces.

Now, INDO-MIM is the world’s largest supplier. Before, Advanced Forming Technology – AFT in Denver, CO — that’s the company with whom Indo-MIM signed a license agreement/joint venture — and then they separated.

DG: I want to talk about G-M just a little bit and speculate a little bit. G-M Enterprises, obviously, is one of your great accomplishments, if you ask me. What do you think it was that made G-M as successful as it was? If you were to look back on it now, what do you think were the keys to making it so successful?

SJ: During my career, I learned that in order to have a satisfied customer base, it is very important to have a talented, dedicated and happy staff. What I believe is “happy, happy, happy”: happy employee, happy customer, happy bottom line. In any business, it’s very important to listen to the customers’ requirements rather than just throw what you have in your basket and offer innovative solutions and then listen. It’s very important that customers feel that they were a critical part of the solution.

The other very important aspect of business is after-market customer service. G-M built up a high level of customer support in family business. In other places, if a customer has a warranty problem or has a problem, they call the home office and the first thing that people say is give [indiscernible]. But listen, at General Electric and Pratt Whitney, these guys cannot [indiscernible]. So, we used to jump on a plane, and we’d go and take care as GM. After solving the problem, we’d say, “Hey, customer, you screwed this thing up. You’ve got to pay us.” I would say, half the customers would pay the full charge, 25-30% of the people would spread the cost, and 10-15% would say, “screw you.” So, it was a good average. That was one of the key defenses between us and other furnace suppliers.

DG: So, your point is, you just immediately responded. Let’s get out and fix the problem, then we can talk about terms later.

SJ: Just imagine: For $5000, half a million-dollar or three-quarter million-dollar equipment is down. It’s not good! So, you go and take care. That’s how you develop a good customer loyalty — they can depend on you.

I’m pretty sure that we had the highest bottom-line in the industry. We had the highest at Ipsen when I was there, it was the highest at Abar, and then at GM.

DG: Well, I’m starting to see a trend here, Suresh. Every place you’ve gone, if you weren’t making a happy bottom-line, it was an issue. You like the happy bottom-line.

SJ: I say, “Happy, happy, happy.” Then, I had a song. In Muslim religion, they raise their hand up, they say, “Allahu Akbar.” I used to say, “Bye GM, bye GM, bye GM.”

DG: ~chuckles~ That’s a good mantra, right there! How many years would you say you’ve been in the industry?

SJ: Over 50.

DG: So, looking back on your 50 years, given your experience, what is the top one or two lessons that you’ve learned? What do you wish you would’ve known when you first started that you know now?

SJ: What I know now, that’s what we practice: respecting employees and rewarding them for their contribution is the fundamental recipe for success. We always treated our employees as a family member and gave them due respect for their contribution. With the right and dedicated employees, it’s very easy to provide quality and timely support to customers. Customers felt very comfortable when they call, even after 10 years, that they were talking to the same highly loyal staff, and business continuity is very important. Customers have said that when they called our competition, every two or three years, they were talking to new people. So, that was very important.

DG: So, maintaining good people basically is the point here, right? For consistency. It certainly helps with efficiency internally, but on the customer facing thing, it’s very good.

SJ: Very comfortable, yes. I used to go late in the morning, 10 o’clock or so, to work and then I’d stay until 6 or 7 o'clock. Many days, the guy in Parts [Department] was still working! And you didn’t have to ask them.

DG: Well, you know, if they find a good work environment, they’re happy to stay and they’re happy to work, which is good.

Let me ask you this question: Were there any disciplines in your life, things that you did/developed, (again, this doesn’t have to be work-related, so much, although it probably has a positive impact on your work), that were very helpful to you in advancing your career, your life, your happiness?

SJ: One was to meet deadlines. We used to have production control meetings. I was given a task, by the president, to design and manufacture a tube and shell heat exchanger. You could buy them outside, but he was bent on making in-house, and so I was given the project. And, like today being Wednesday, at 8 o’clock we were having a production control meeting and I did not do anything, and all the drawings were due tomorrow. In the production control meeting, people were laughing at me because they were looking at throwing darts at me. In a way, they were saying, in a calm voice, “Son of bitch, he puts pressure on us, but he doesn’t do his own job.”

Do you know, I never went home? And the next day I was supposed to go on a trip — I had a 10 o’clock flight from O’Hare. I worked through the night and at 7:30am when the engineering crew came in, I gave them all the drawings, bill of material, left for O’Hare, and took a nap on the plane.

What I’m trying to convey is: Meeting deadlines and commitment, to me, is always number one. No excuses.

DG: Get it done and get it done when you say you’re going to get it done.

SJ: That helps you to expect from other people, when they see you, that you do that, so they follow.

DG: They know you’ve got a platform to stand on when you’re talking to them about doing the same thing.

So, you just talked about a very interesting situation where you worked through the night to get something done. This kind of sets up for the next question, and that is: How did you, Suresh Jhawar, handle the work/life balance? Or was there no work/life balance, was it all work?

SJ: You know, it was difficult when I was at Abar, because I took a big responsibility, and I was traveling internationally quite often. So, I missed a lot of family functions of children in their school and then, finally, when Andy [son of Suresh] was getting an award at his high school, I was coming from Europe, either Poland or some place, and the plane comes to Chicago, and I have to change. And the flight was late, so I missed my connection. Now it became difficult as to how to get to Philadelphia to attend that awards ceremony for my son. I called Veena and said, “You guys go ahead. I don’t know whether I’ll make it or not.” I went from one airline to another. I got on a plane, reached Philadelphia airport at the time when the program started, but I was at the school at the right moment when Andy’s name was called. I was there!

DG: That is great! Well, you do what you can, you know? You’ve got to get there. And you’ve got what, two children, correct?

SJ: Yes, Andy and Sheri.

DG: Looking back on your career, what was one of the most memorable things that happened to you?

SJ: At GM, it was easy, because Veena and I worked together. It was pretty balanced; we were both colleagues and had the same goals. It was much easier compared to other places.

Coming back to that: I was an average student in India, a B student, or so. My parents didn’t want me to leave India. But I was interested. I researched UK, Germany and U.S. I found that in the UK and Germany, it would take me 4-5 years to get a Bachelor or Science degree in Engineering. The cost was half of the USA. But, in the U.S., I could do it in 2 years, and the reason was because I already had a Bachelor of Science degree from India, so they were giving me advanced credit, so I started as a sophomore. I did my undergraduate in 2 years here and the 2-year cost was the same as 4 or 5 years in UK than U.S. I used to go the U.S. library, do this. My parents didn’t support me, but I went and got my passport, got visa and I was determined. I landed in 1962 to the U.S..

That is the most memorable, yes.

DG: Coming to the U.S. And achieving it even though your parents weren’t necessarily fully on board.

SJ: The other thing to highlight is: Before marriage, when Veena and I met many times, Veena had rejected over 20 people. She even told me no. But she said, “You have to tell it to my father because I cannot say that I’m rejecting you, because they are tired of you.” She was surprised when I said, “Okay, I will.” And the other boys, they would not leave her. So, that brought us together.

By the way, in front of my father, I was a very shy guy. I didn’t speak much, just, “Yes, sir. Yes, sir. Yes, sir.” She thought, up to marriage, “What kind of a guy is this? So timid!” Anyway, then we got on a plane, and I ordered two scotch, and she saw me entirely different! That was another highlight.

DG: Last question for you, Suresh: If you were to give some of the young people in the industry a little advice, what would you give them? I can say this as a fellow ‘old-timer’ in the industry, what would you say to them?

SJ: The most important thing is to treat your employees like you treat yourself. When I worked at GM, out of any of the other places, I didn’t work as being “the boss” or on a high platform; I worked shoulder to shoulder with them. That gained their trust. I trusted them, they trusted me. That is very important. Business cannot succeed unless you have people — the right people and dedicated people.

DG: Well, Suresh, thank you very much. I appreciate the time that you spent with us. I know, personally, you’re one of the guys who is always very positive and very encouraging to me. . . . Even though you insulted me a lot! ~chuckle~

SJ: That was in a friendly manner! I don’t stop anybody on the street and insult them. Only between friends. ~chuckle~

DG: On a more serious note, I have appreciated your encouragement over the years. You’re a good friend and a person who has always been encouraging. I appreciate that.

Thanks for your time, today.

Doug Glenn

Publisher

Heat Treat Today

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio .

.

See Fives North American Combustion, Inc. listing on Heat Treat Buyers Guide.com

Heat Treat Radio #78: Heat Treat Legend Suresh Jhawar Read More »

DG: I want to jump back onto the labs you were talking about. Very briefly, how many where are they?

DG: I want to jump back onto the labs you were talking about. Very briefly, how many where are they?

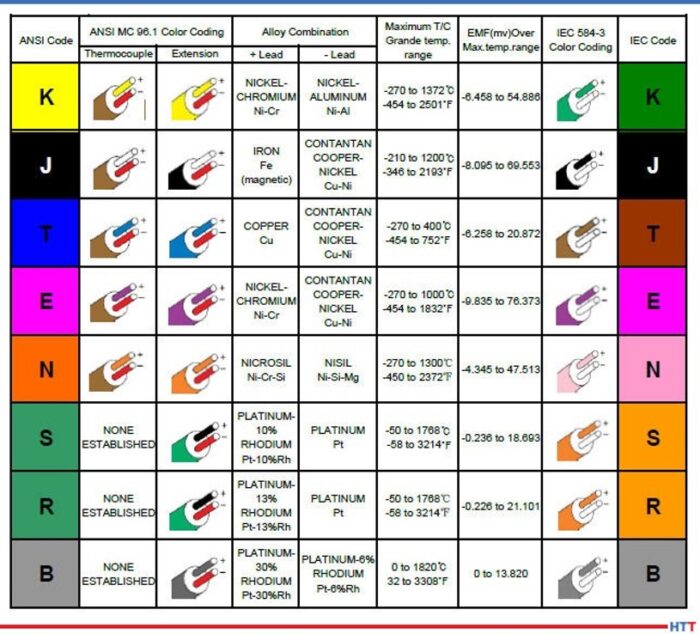

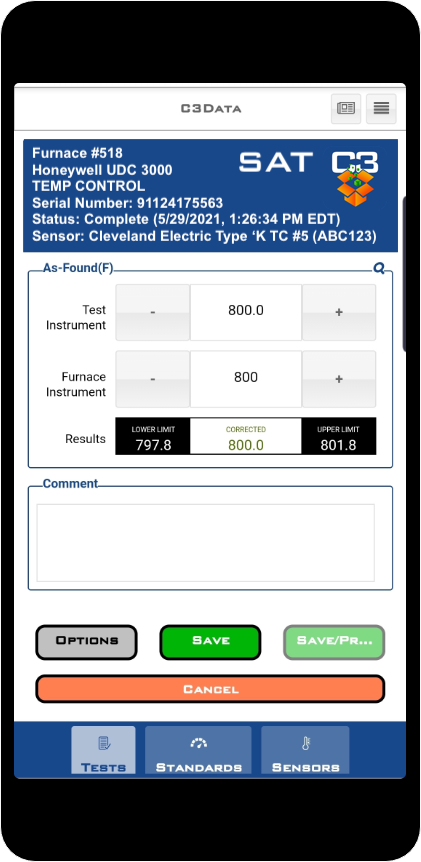

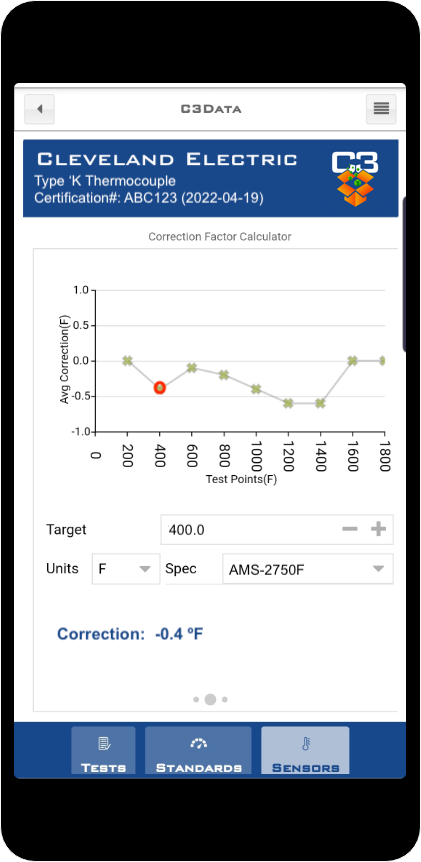

MW: Yes, absolutely. Now the tenth of a degree thing, I believe, is going to be extended for another year so that users are going to have one more year for that. The date we’re hearing and looking at is the end of June, so I think June 29th, which I think is the two-year anniversary of Rev E to F, so it will be coming out then, if nothing else changes.

MW: Yes, absolutely. Now the tenth of a degree thing, I believe, is going to be extended for another year so that users are going to have one more year for that. The date we’re hearing and looking at is the end of June, so I think June 29th, which I think is the two-year anniversary of Rev E to F, so it will be coming out then, if nothing else changes.