Heat Treat Today publisher Doug Glenn sits down with Ed Valykeo from Pelican Wire in the first of a three-part series on all-things thermocouples. This first episode covers the history, types, vocabulary, and other basics of understanding how thermocouples work.

Heat Treat Today publisher Doug Glenn sits down with Ed Valykeo from Pelican Wire in the first of a three-part series on all-things thermocouples. This first episode covers the history, types, vocabulary, and other basics of understanding how thermocouples work.

Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited transcript.

The following transcript has been edited for your reading enjoyment.

Doug Glenn (DG): Ed, why don't you take a minute, as we typically do on these interviews, to talk briefly about you and your background especially your qualifications for talking about thermocouples.

Ed Valykeo (EV): I've actually been in the wire and cable industry for a little over 40 years now. I actually first started in the industry as, well maybe not a grunt, but certainly I was called a “melter's helper.” I worked at a company called Hoskins Manufacturing in Ann Arbor, Michigan where we actually melted the raw materials to make thermocouple wire, resistance wire, and a whole host of other things. I was actually the guy that, after we got done pouring that molten metal into the molds to make the ingots, was cleaning up all the mess that happens after you pour and you're pulling those ingots.

That's really where my career started, with Hoskins. As a matter of fact, it kind of ran in the family. My dad retired at Hoskins with 42 years of service with Hoskins, so it was kind of a natural progression that, eventually after I got out of the service, I ended up joining Hoskins. I was there about 18 years at Hoskins Manufacturing, again, starting out right at the bottom. I worked my way up to becoming an associate engineer working in the R&D department. That's where my career really started focusing a little more on thermocouples. I enjoyed working with thermocouples. We were developing some new products using thermocouple wire and things like that.

Ever since then, I've kind of stayed in thermocouple arena at some of the other places I've worked. After I left Hoskins, I started working for companies that insulated wire. So, we were taking the wire, like we made at Hoskins, and we were putting a whole host of insulations on it from ceramic braid to extruded products and things like that. And, again, both the companies, and even the one I'm currently employed with at Pelican, but before that I was working for a company out in New Hampshire called PMC, are real similar, it's just we insulated wire. So, we purchased the raw materials (raw wire from Hoskins or whoever) and then insulated it.

DG: For the unbaptized in this topic, what are thermocouples, how do they work, how do they come about, and then are the modern-day thermocouples any different than the thermocouples of old?

EV: I always start out with a little bit of history about thermocouples, whenever I'm talking about them, just to give people background. Thermocouples were introduced in the early 1800's with the most significant developments taking place in Europe.

One of the very first gentleman that worked on it was Alessandro Volta. You can probably recognize the name because Volta actually is the volt, today, which everybody recognizes, not just with thermocouples but, obviously, in the electrical industry too. He basically built a couple thermopiles using metals, silver and zinc and some cloth in between them, soaking them in salt water, and discovered that it would produce a voltage. That's kind of how it got started. The significance of that discovery was that there is a source of steady and reliable current flow from using dissimilar metals and saltwater and things like that.

Over the years, many others have experimented with the phenomenon. Probably the most famous, anybody that's in the thermocouple industry will hear it a lot, in 1821, Thomas [Johann] Seebeck announced that he had discovered that when two dissimilar metals were placed in a closed loop and one of those junctions was exposed to a change in temperature, electrical current was produced. This production of the electromotive force and electromatic force is the electric current is known as "the Seebeck effect" or "Seebeck coefficient." It was, obviously, much later, before everything was understood and correct mathematics, but Seebeck's name will always and forever be associated with the discovery of thermoelectricity and thermocouples. Again, even to this day, even ASTM books reference Seebeck coefficient.

Some other gentlemen that we involved, again you'll recognize some of these, were Michael Faraday, Georg Ohm, Claude Pouillet, and Antoine [César] Becquerel. It was Becquerel, actually, that suggested using Seebeck's discovery for measuring high temperatures. He proposed the strength of the current generated was proportional to the change in temperature in exactly the principle behind the thermocouple. We're measuring temperature, whether it's 200 degrees or 2300 degrees. That's how the modern day thermocouple got started way back in the early 1800's.

DG: And the modern-day thermocouples are, essentially, the same as that? Have there been any major changes?

EV: In reality, Type J was the first thermocouple to really be experimented with. After Type J, then some additional thermocouple types came on board. People experimented with other metallurgical compositions to develop different millable outputs.

DG: Let me understand: Type J, what that basically the first type of thermocouple that was developed?

EV: Let me back up a little bit. Actually, the early metal thermocouples were based on what we can call noble metals. Noble metals are rare earth elements such as platinum, rhodium, tungsten and uranium. The problem with the noble metals is that noble metals are much more expensive than our base metal thermocouples, or what we call base metal thermocouples, today. Base metal thermocouples, today, typically the compositions are just a handful of elements. You have iron, nickel, chromium, copper and things like that, which is considerably cheaper than the noble metals, the platinum and rhodium and things like that.

DG: I want to learn this history a little bit, because it's just kind of fascinating to me. So, the very first ones were made of noble metals, primarily. So, they would put those together and then, basically, we said, "This is great but it's way too expensive. Can we get the same effect, if you will, (the difference in voltage, or whatever, between dissimilar metals), if we use a little less expensive metals?"

EV: Right.

DG: You’ve said there is a difference voltage when there's a difference in temperature.

EV: The EMF (electromotive force) generated by the thermocouple is linear. So, at 200 degrees, it produces this amount of voltage, at 300 degrees, it produces this much. All the thermocouples are, basically, the same principle. It's very linear. That's one thing that is good about a thermocouple- the EMF output is linear. You aren't producing a millivoltage at 200 degrees and then at 300 it goes down and then at 500 it goes back up; it's linear proportional to the temperature.

DG: I have heard in the past, and you mentioned it here, maybe we can discuss it a little bit: noble metal versus base metal. Obviously, we know noble metals, you mentioned what those are. Those are expensive; they work to do the same thing. Base metals, though, tend to be what? Which metals?

EV: As I already mentioned, the nickel, chromium, copper, and others.

DG: And those are, in fact, just less expensive, right? Essentially, they do the same thing but they're less expensive.

EV: Exactly. But, there are some other differences, too, between the noble metals and the base metal thermocouples. When you're talking noble metals, the platinum and the rhodium, and things like that, they can handle much higher temperatures than even the base metal thermocouples.

DG: I'm going to make an assumption, but probably the vast majority of the thermocouples used in the heat treat industry are probably base metal, although, I'm sure they've got some specialized ones for high temperature, which probably jump into noble metals.

EV: Absolutely. A lot of the base metal thermocouples are used in the load sensors where they're putting multiple sensors in and then the oven may be controlled by a noble metal.

DG: The different types of thermocouples. You mentioned, and I've forgotten the letter already, that there are different types. Was it Type J you mentioned?

EV: Yes, Type J.

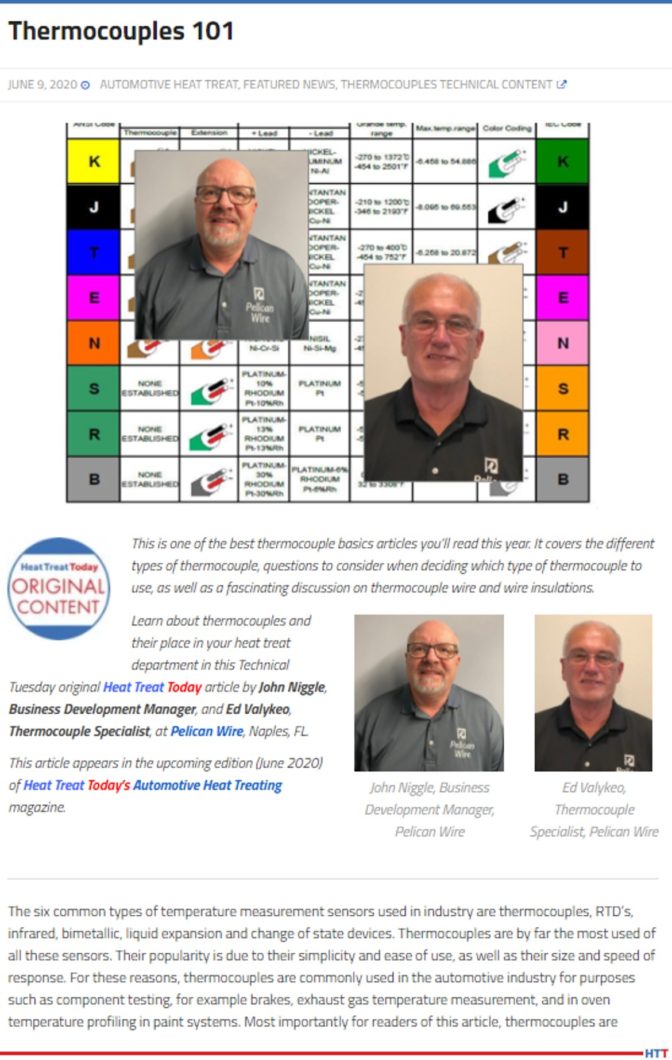

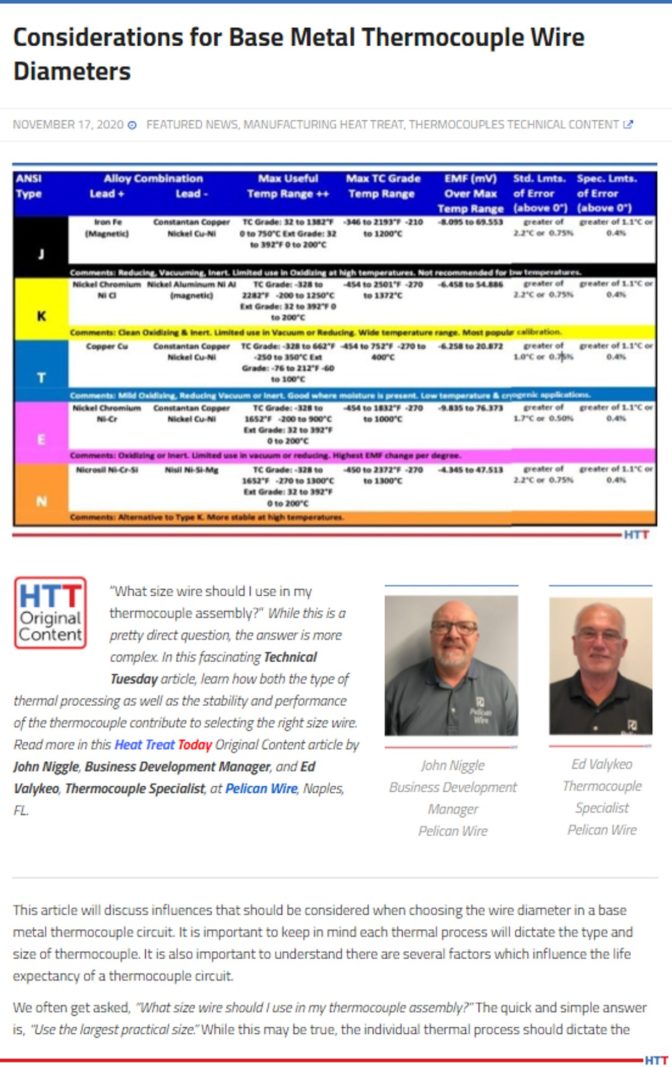

DG: OK. We've done a study recently asking about what's the most popular one in the heat treat industry, but I know we listed down there J, E, K, N, and T. Can you run us through those and tell us what are the differences, and whatnot?

EV: J, E, K, N and T are the most common noble metal thermocouples. Obviously, you've got two dissimilar metals or, what we refer to in thermocouples, two legs of the thermocouple – the positive leg and the negative leg. So, for instance, on a Type J thermocouple, you're using iron as a positive leg, which is basically pure iron, (there are some coatings on the iron to help against oxidation and things like that), and the other leg is a copper nickel alloy. That makes up the two legs of the Type J thermocouple.

If we look at Type K thermocouple, the negative leg is the KN which is, basically, just high nickel with a little bit of chromium; the KP leg, or the positive, of Type K is higher content nickel chromium. There are also some other minor elements.

With Type T, the positive leg is pure copper. The TN leg is, again, a copper nickel alloy. So, when we talk about Type E, what is interesting is that with the Type E thermocouple, you're actually taking the Type KP leg and matching it with the TN leg. So, again, it's just a mismatch or some hodgepodge of some legs.

DG: So, you're using some lingo that I'm just picking up on and I want to make sure our listener's are, as well. You talk about a P and an N leg. Obviously, you didn't say it, but you're talking about a positive leg and a negative leg.

EV: Yes, I'm sorry. KP and KN. So it's K positive and K negative leg.

DG: Great. So, with the Type E, you're taking a few and switching them around and matching them up and seeing what you can come up with.

EV: Yes, that's the E, and I already mentioned the T. N is a relatively newcomer to the thermocouple industry. I say new, but it's still probably 40 or 50 years, I'm not sure when it was developed. But, again, the Type N is similar to the Type K where the KP leg is a nickel and the KN leg is nickel and some silicon. So, it's just a little bit different composition from the Type K thermocouple. But, there are some differences.

Some of the differences, when you're looking at the different types of thermocouples, for example, Type E has the highest EMF output of any of the thermocouples. Your question might be, "Well, why wouldn't we just use Type E because it has the highest output?" What the higher EMF output means is that the sensitivity is a little bit greater in the Type E thermocouple. Then why wouldn't we use that throughout all the industries? Well, the short answer is, a couple things: Type E has a limited temperature range, because, again, you're using that TN leg which is copper nickel alloy and the melting point of a copper nickel alloy is much lower than a nickel chromium alloy. So, that's some of the differences, and with all the thermocouple types, also.

Each one has their own EMF output at certain temperatures but one of the biggest considerations is, really, the environment that you're using the thermocouples in. Type K has good oxidation resistance; Type J, not so much, because you've got a pure iron leg which is going to oxidize much faster. That's some of the differences between the individual thermocouple types.

DG: I assume that if there's oxidation, or any type of corrosion or anything of that sort, it's going to change the EMF, it's going to change the reading and therefore that thermocouple, out the door she goes.

EV: Absolutely. And there have been even some recent changes in some of the specifications that some of the heat treaters are using nowadays where they finally realize that these thermocouples do deteriorate over time and so they start limiting the amount of uses that each thermocouple can be used in, in a bunch of different applications, but heat treating mainly.

DG: Let's pause for just a second and do a little vocabulary. You've mentioned EMF a couple of different times. Could we have just a brief review of that just to make sure? Also, I've heard about millivolts. Are those two things related? If so, how?

EV: EMF stands for electromotive force. It is, basically, when two dissimilar metals are put in contact with each other, a small voltage is generated. When we're talking about millivolts, that's exactly what we're looking at: a millivolt is 1/1000 of a volt. It's a very small amount. If you look at some of the millivolt outputs for some of these thermocouples, at 200 degrees, for example, you're putting out .560 of a millivolt. So, these are small.

DG: And you're saying that it was the Type E that has the highest millivolt of all, so the current that is produced between those dissimilar metals is the highest, but you can't always use that one because in certain temperature ranges you're going to melt one of the legs.

EV: Exactly.

DG: The millivolts are measured by what? I mean, it goes into an instrument that is able to read that? What is that instrument?

EV: Actually, some DVMs (digital volt meters) have the capacity to measure in the millivolt range. So, it could be as simple as a digital voltmeter. But, in the industry, we have temperature controllers, things like that, that you hook a thermocouple up to and it measures the EMF and then it converts it into a temperature.

DG: It will measure that millivolt and then tell us what the temperature is?

EV: Right. With the instrumentation nowadays, it has the formulas in its memory, or whatever, and can convert that millivolt into an actual temperature that you actually read on a meter.

DG: We've got an EMF which is measured in a millivolt. It's going to travel across a long wire, I assume, to some place where it's going to be read. Let's talk about that wire a little bit. The impact of this, whatever EMF is being created, millivolt, what about that wire? Tell me about it and what do we need to be careful of, etc?

EV: We're actually saving that for another podcast, but I will touch on it a little bit. So, there are limitations on the length of the thermocouple. There are a lot of different mindsets, but probably the one I've heard the most is no longer than 100 feet. So, you have your thermocouple sensor and that arrangement, the configuration, can be a number of ways. At PMC Corp. we insulate the wire. You could just take that insulation off at the end, weld the junction there, stick it and [. . .] then run it to a meter.

But in other industries, you may have it in a ceramic tube because of the temperature it's being used at. You have a ceramic tube with a connector at the end, you may run what we consider an extension wire from that point all the way back to your instrumentation. Again, the general rule of thumb, is 100 feet.

DG: Let's talk about that wire with the different types of thermocouples. What do we need to be sensitive to? What do we need to be careful about?

EV: Again, temperature range is probably the first consideration, but then also the environment that it's in. Again, each thermocouple has its limitations on the environment. Some are good in a vacuum, other thermocouples are not good in a vacuum. Some thermocouples are good just in air, (like Type K), but Type J is not so good. It still can be used in air but it will oxidize faster.

Like I said, in an environment of a vacuum, some thermocouple elements will actually leech out or evaporate out and that definitely would cause a problem with the EMF output and would have an erroneous reading. Certain acids you can use some thermocouples in, others you can't.

DG: With all of this pyrometry stuff going around, especially the AMS2750 revision, there are a lot of places where the tightness of the tolerance on the temperature really needs to be paid attention to. Are some thermocouples inherently tighter tolerance, where they can go down to + or –2, or less than that?

[blockquote author="Ed Valykeo, Pelican Wire" style="2"]Special limits of error is the tightest tolerance, and that's according to ASTM. But, there are some customers and some companies that want tighter tolerance material. So, when we talk about that, that's really a special order. Now you have to back all the way back up to the melters that melt these elements and make the thermocouple wire. It's on them to produce something that is a tighter tolerance. [/blockquote]

EV: Again, that was something we were going to touch on a little bit later, maybe on another podcast, because it can be a whole category on its own.

But, yes. If you think about in general, overall, when we're thinking about the different thermocouple types, they basically all have the same tolerances according to ASTM. The rule of thumb, that we kind of use, is from say 200 degrees to 500 degrees, the tolerance on all thermocouples are + or - 2 degrees if you want special limits of air material.

Now, there are other tolerances. In the thermocouple industry, you’ll here – at least calibration-wise – you'll hear special limits of error, standard limits of error and extension grade. Special limits of error is the tightest tolerance, and that's according to ASTM. But, there are some customers and some companies that want tighter tolerance material. So, when we talk about that, that's really a special order. Now you have to back all the way back up to the melters that melt these elements and make the thermocouple wire. It's on them to produce something that is a tighter tolerance. Once that metal is poured in that mold and it's processed down the wire, it is what it is. When they calibrate that wire, you can't really do a lot with it to change the EMF output, per se, other than there are some heat treat operations that can, what they call, stabilize, and there are processes to oxidize thermocouple wire, and things like that, but you're pretty much stuck with EMF right from the melt.

DG: And it's dependent on the material composition or quality of the material.

EV: Absolutely. In some cases, they may melt 10 melts to get 2 special limit of air thermocouple types. I don't think it's quite that bad, bur from my early melting days, we've had to downgrade many a melt because it didn't quite meet the tolerances.

DG: Just reviewing, we talked about the basic history, how they got started. We talked about the difference between noble versus base metal thermocouples. We talked about the different types. We defined EMF, electromotive force. We talked about millivolt a little bit. We talked about the wire, the differences in what we need to pay attention to as far as wire, and some other considerations like temperature range, calibration tolerance and environment.

EV: Just so you know, the only base metal thermocouples there are, at least what ASTM recognizes, are the Type J, E, K, T and N. We covered all the base metal thermocouples.

DG: Just out of curiosity, a noble metal thermocouple, what are those?

EV: There is a fairly large list of those. You've probably heard of thermocouple Type R or Type S thermocouple. Those are all made with noble metal thermocouples. It's not really considered a base metal, but tungsten uranium thermocouples. Those are in more the noble metal category Type C. There is even development of some other additional noble metals: gold is used. Thermocouples are made out of gold.

DG: Those could be expensive. Of course, some of those other metals are more expensive than gold, so, who knows?

Well, that's very interesting. So, J, E, K, N and T are all base metal thermocouples.

I want to make sure that we give appropriate credit to your company. We talked about the fact that you're from Pelican Wire, part of the wire expert group. I want to make sure that our listeners know that they can go check out your website which is pelicanwire.com. You're not obligated to do so, but would you like to give out any other information where they can get a hold of you?

EV: Yes. Through the Pelican website, you can certainly get a hold of me. Our number is on the website. It's 239-597-8555 and it goes through a central board. If anyone wants me, they can just ask for me through the operator.

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.