Heat Treat Radio host and Heat Treat Today publisher, Doug Glenn, talks with Matt Wright, the chief marketing officer at C3 Data, to hear how the company has reimagined furnace compliance to fit in your pocket.

Heat Treat Radio host and Heat Treat Today publisher, Doug Glenn, talks with Matt Wright, the chief marketing officer at C3 Data, to hear how the company has reimagined furnace compliance to fit in your pocket.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

The following transcript has been edited for your reading enjoyment.

Doug Glenn: Matt, Welcome to Heat Treat Radio. This is your first time on.

Matt Wright: It’s good to be with you.

DG: I do want you to spend a little bit of time giving our listeners a little bit about your background and then, also, if you don’t mind, a quick summary of what C3 Data does, just so our listeners have a concept.

MW: I’ve been in the heat treat industry now for about 15 years. My brother, Nathan, and I together, we own a few — twenty-five — accredited pyrometry labs. C3 Data really comes as an outgrowth of that. Looking for an opportunity or way to reduce errors, a human element, and to save time with all of our technicians doing all the work that they’re doing. And so, it really became something that we did for ourselves and realized that it could be something that the industry as a whole could use.

When you look at our industry, there are two ways that you can comply with the AMS2750 CQI-9 specifications. One is what I would call the “roll your own method” which is what everyone has been doing from the beginning: that is using a whole panoply of different technologies, whether that’s an Excel spreadsheet, a clipboard, post-it notes, or what have you — anything and everything that you can do to try to remember to do all the things that need to be done, and then you go to the audit and hope that nothing fell through the cracks. What C3 Data does is takes all of those requirements and starts with the spec and encapsulates everything in one platform, one system, so you don’t have to think about and remember to do those things, you just follow what we have you do, and you come out and you’re ready for your audit.

DG: I want to jump back onto the labs you were talking about. Very briefly, how many where are they?

DG: I want to jump back onto the labs you were talking about. Very briefly, how many where are they?

MW: We’ve got one in Ohio and one in Mexico that has three different offices in Mexico.

DG: And these are metallurgical labs, or did you say testing labs?

MW: They are labs that go on site to perform temperature uniformity surveys, system accuracy tests, instrument calibrations and those types of things.

DG: Let’s talk about compliance. Compliance with AMS2750 CQI-9 NADCAP is really an issue that is important to a lot of our listeners and readers, primarily those manufacturers who have their own in-house heat treat and have their own furnaces. Let’s talk about some of the latest developments, the latest technologies in that field. What are you seeing out there, Matt?

MW: When I look at our industry, one of the things that is the biggest challenge is the flow of information — getting information from where it resides to where it needs to be in the format that it needs to be. I think the technologies that have been successful in our industry are technologies that help lubricate that flow, if you will. A good example, I think you had mentioned some of the specs, but one of them is ITAR, the International Traffic in Arms Regulations specifications. In that case, you’re trying to prevent information from going to malign influence and so they’re going to use things like the Cloud and mobile technology. And those are the platforms that we’ve been built on, as well. But we’re kind of using it in reverse; we’re trying to disseminate information and getting it there as quickly as possible. So, the Cloud and mobile technology, I think, are the two biggest forms of technology that have been really helpful.

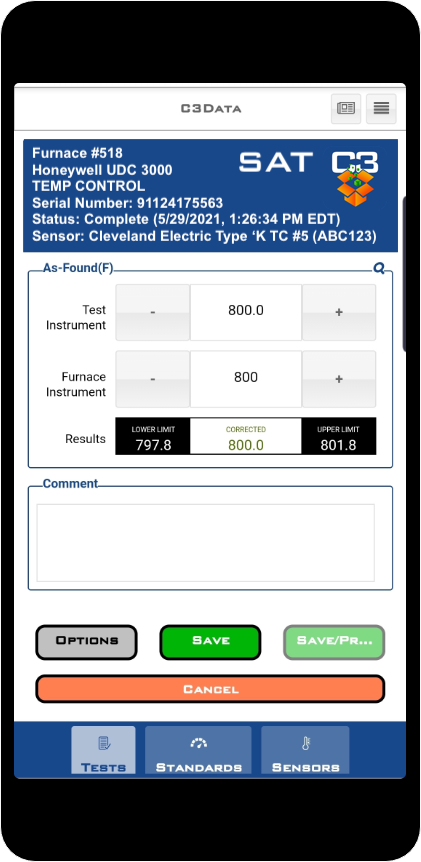

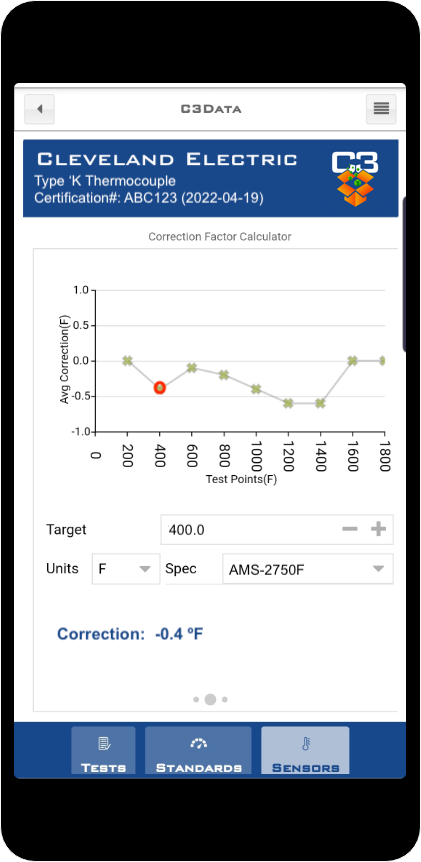

A couple other ones that we’re actually using that we’re seeing a little bit more and more of is OCR- optical character recognition. This is the ability to take a static document that has information on it and digitize it and get it to where it needs to be. We’re using that to be able to scan, for example, thermocouple cert, so that our customers, irrespective of who they’re buying their certs from, can just take a cert, scan it and build it right into their platform so they can use it to do an SAT in real-time.

Another one is the QR code. You know, with the things that are going on, it’s kind of made a comeback in recent days. Now you can get your wine list by scanning a QR code at the restaurant. Well, we’ve been using it since before it was cool to do that; we’ve been using to scan your thermocouples or your field test instrumentation, so you don’t have to go and look up something in a database or a table, you can just scan it in and, boom, you’re ready to go.

DG: This OCR is interesting regarding the certifications on the thermocouples. So, a thermocouple comes in, it’s got its stats and whatever you’re scanning, that becomes part of your data, if you will, correct? And are they using it for anything else? For example, I’m thinking in my mind, a company who wants to transition over to using a system like yours, perhaps they’ve got a lot of historical documents that, at least, would be helpful. Is that also an application?

MW: Certainly, a potential application could exist for that. We’ve got other tools with forms and things that we’ve put in place to make that transition from going from, what I call the “roll your own” in the static thing and pulling all of that information in. We’ve really made it, and strive to make it, more and more seamless every time.

DG: And the QR codes? Are you using those on furnaces, on thermocouples, or where are you using those?

MW: Any equipment that you use, whether it’s a thermocouple, a field test instrument, a data logger, any certification data that is associated with that, you can print a QR code and affix it to that. You’re not having to go and enter that in manually, you’re just scanning it in using our mobile app that has a QR code scanner built right in — it’s pulling that directly in. The whole idea is to reduce that bottle neck, if you will, and to get that information flow in so that these guys can do more value at a time out on the plant floor.

DG: I also wanted to ask you, because you mentioned about Cloud-based and mobile apps and things of that sort — let’s talk about security for just a second. I just got done doing an interview with a guy by the name of Mark Mills that hasn’t been released yet. He’s a fascinating guy and I’m going to give that one a plug right here- you need to listen to that when it comes out. But he was talking about cybersecurity- he wrote a book called The Cloud Revolution. I’ve also heard at some of the industry meetings that there have been real concerns where some of the larger companies are not wanting their data to go “outside,” if you will- they don’t want to break the ceiling and get into the Cloud, they want it on site. Are you guys seeing much of that? If so, how are you handling that?

DG: I also wanted to ask you, because you mentioned about Cloud-based and mobile apps and things of that sort — let’s talk about security for just a second. I just got done doing an interview with a guy by the name of Mark Mills that hasn’t been released yet. He’s a fascinating guy and I’m going to give that one a plug right here- you need to listen to that when it comes out. But he was talking about cybersecurity- he wrote a book called The Cloud Revolution. I’ve also heard at some of the industry meetings that there have been real concerns where some of the larger companies are not wanting their data to go “outside,” if you will- they don’t want to break the ceiling and get into the Cloud, they want it on site. Are you guys seeing much of that? If so, how are you handling that?

MW: It’s a mix. We do see that. Every corporation has their own policies and procedures and what they’ve determined is a safe way to operate. So, on one side of the spectrum, we’ll get people that will be concerned and say, “Nothing in the Cloud,” and we have to have that conversation. Usually, the conversation revolves around what is the purpose of this information? And really, when you peel back and look at it, if someone were able to access the information in our system (which we have very tight security around), the only thing they’re going to find out is the very thing that those same preparations are bragging about on their website, and that is that they’re NADCAP compliant. There is no process-related data, there is no secret sauce involved in anything that we’re doing and so, it’s not something that we believe, and most people do end up seeing it our way that needs to be curtailed from a Cloud perspective.

DG: I know a lot of companies’ concerns are not so much that something will get out about them as it is this Cloud connection is a gateway for the nefarious amongst us to break in and get it. I’m sure you’re seeing that, right? Let me ask you it this way: What percentage of your clients are actually saying to you, “Listen, we want this to not be Cloud-based, we want it to be just on-site.”

MW: If I could swag, I would say maybe 5–10% ask the question, “Hey, is this something that we can just have locally because we would just like to have it for ourselves?” And the answer is, it’s not; it’s not something that we can have locally, just by nature of what it is — it’s an ongoing, continually improving and updated thing.

DG: Let’s talk about another hot point that we have here besides internet security. I don’t know if you guys have been affected by this, but it has to do with supply chain issues. We’ve got Covid to blame, we’ve got Russia to blame, we’ve got all kinds of things as far as supply chain. Are you experiencing any of that yourself for your business or are you seeing it from any of your customers?

MW: I think we are fairly isolated from that in that we’re not producing a tangible product; we’re a software company. Happily, we’re not experiencing that so much. I will say that, from our customers’ perspective, the big catchphrase now is “flexibility.” With those things that you mentioned, the ability to be able to adapt to not knowing from one day to the next if the guy that was supposed to do your SATs or TUSs today is even going to show up because he might test positive for Covid, or something else, really drives home the need to be flexible — to not put all your eggs in one proverbial basket. We’re striving asymptotically, if you will, to get closer and closer to that point where someone who’s never done a calibration before, can pick up an app and literally, the same day, start doing calibrations. There are a lot of hills to climb and obstacles to overcome, but we’re pretty close and we’re going to strive to keep doing that so that people don’t have to worry about what if this guy quits, or what if this guy gets a promotion? The system is going to run, and they can pick up and run with it with the next guy.

DG: When we talk supply chain, I start to think to myself, to a certain extent, I start to think internationally a little bit because a lot of the issues are bottlenecks at the border and things of that sort. But it makes me wonder — how about you guys, C3 Data, are you just North America or are you seeing business outside?

MW: Being a software company, one of the benefits of it is that you don’t have to ship anything anywhere. Being a U.S.-based company, we started out here and most of customers are here. We have a fair number of customers in Mexico, we have a few in the United Kingdom and we’re expanding currently, bringing on customers in France. Right now, we’ve got about four or five different languages that the website and the app is translated into, and we’re interested in expanding. It’s a great question and one that we’re really excited about — being able to not just be so parochial in the United States, but to expand into Europe.

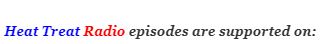

DG: Tell me a bit about the mobile app. Let’s say you’re a manufacturer and you’ve got an in-house heat treat department. How often are you going to be using that mobile app as opposed to how often are you going to be using a desktop application, and how is the mobile app used?

MW: The decision to go with the mobile app came from our experience as a heat treat lab. Having to schlep around a laptop in a laptop bag or a cart with a computer on it, it’s really kind of a pain, quite frankly. Virtually everyone owns a cellphone. So, if we can put this into the power of a cellphone and enable that person to carry one less thing and to have the flexibility to not need to have to have that to do an SAT, to do a calibration, to change a sensor and those types of things, that’s what we wanted to do. You can use the app, you can run it on a laptop if you wish, and we have a few customers that just do that, but most of our customers (I would say over 90%), use the app, and depending on how fat their fingers are, they might go to a tablet.

DG: On a typical day when they’re using the app, they’re using it to do what? Run us through what would be a typical application.

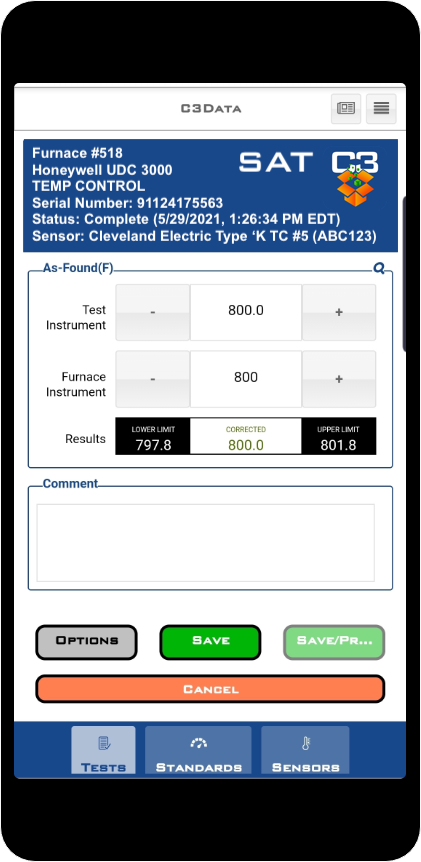

MW: The mobile is primarily just used to do instrument calibrations and system accuracy tests. When you go out to do these tests, there is a whole lot of information that you need to have, and you need to be able to record information. Everything that you need is on the app, whether it’s defining what test sensor you’re using, what field test instrument you’re using, what furnace class the furnace is — everything is there. So, they’re using it just to record information. As they’re using that app and putting that information in, their reports are literally being generated in real-time and waiting for the quality manager to review whenever he or she wants to.

DG: I wanted to ask you about the different standards that you guys are covering. The three biggies we always think about are NADCAP, AMS2750, and CQI-9, and I’m sure you’ve got compliance with all of those. Are there any other major ones that you think any of our captive heat treaters might be interested in? I know the commercials will be interested in all of them, but any our captives might be interested in?

MW: Yes. Those two are the big ones — the AMS2750 spec and CQI-9 — that’s going to cover your aerospace and your automotive specification. We have the ability to give our customers, and a lot of our users do take advantage of it to create their own custom specs. They can just define their custom specs, their criteria, their frequencies, and then use the same platform that we built for these two specs, out of the box, to drive the compliance to whatever spec they want. So, it’s very open — it’s kind of agnostic in that regard. But we just built in those two AMS2750 and CQI-9 specs because that’s going to hit over 90% of what everybody wants.

Just a thing about those specs: Whenever those specs revise, like when CQI-9 went from rev 3 to 4 and when AMS2750 revision from E to F, and now, coming up in June when it revises to G, one of the benefits of having a Cloud-based solution is that all of our customers, when it went to F, all they had to do was log into the portal, find their furnace and go from E and select F and they’re off and running. That’s all they had to do. No training is required. It saves a lot on time of training, and you don’t have to redo the paperwork. The reports and all those things are now current revision.

DG: And Rev G of AMS2750 is probably out. I was just at some industry meetings and the big stink about the AMS2750 is going to a tenth of a degree on some measuring tools and things of that sort. Are you guys are able to handle that? I assume, being the software guys, it probably doesn’t really matter to you whether it’s a tenth or a hundredth or whatever. But you can cover that?

MW: Yes, absolutely. Now the tenth of a degree thing, I believe, is going to be extended for another year so that users are going to have one more year for that. The date we’re hearing and looking at is the end of June, so I think June 29th, which I think is the two-year anniversary of Rev E to F, so it will be coming out then, if nothing else changes.

MW: Yes, absolutely. Now the tenth of a degree thing, I believe, is going to be extended for another year so that users are going to have one more year for that. The date we’re hearing and looking at is the end of June, so I think June 29th, which I think is the two-year anniversary of Rev E to F, so it will be coming out then, if nothing else changes.

DG: The fellows I was hearing from were saying basically there is talk of the extension, but they’ve got to get it passed to actually get the extension, otherwise end of June is the date that most people are going to have to nail that with.

Your C3 Data tool is basically Cloud-based, portable, whether it’s website, phone, tablet or whatever, to help people comply. When the auditor walks in to get the information they want, how easy is it for your clients? What do they need to do? I assume this is where the real time and money-savings come in, correct?

MW: Correct. What we like to tell people is, in a nutshell, C3 Data is going to save you time and help you pass your audits. The time saving is happening all during the year. Every SAT you do, you’re saving an enormous amount of time because you’re not writing in your reports, you’re not doing any calculations — you’re aggregating and gaining time throughout the year.

You’re also going to gain time in your audit preparation because, as you mentioned, when you log into your portal, your ability to find all of your documentation, along with our furnace dashboard which shows you, furnace by furnace, the compliance status of each one of them. You can see, in real-time, the compliance status is a huge timesaver and a real peace of mind that you can walk in with your hand on your heart and know from the auditor’s perspective, you’re going to have a good experience, because if he wants to see something, it’s very easy to find and you’re well prepared.

DG: Timesaving has got to be enormous. I know there are a lot of companies investing a lot of time in these audits and in compliance-related things.

You guys do a lot of work in this area. Are there any good tools out there for any of our viewers/readers if they want to go and find out more information, whether it’s dealing with compliance, what is AMS2750, what is CQI-9, any of that kind of thing? Any suggestions from you on where people might want to go?

MW: On our website, c3data.com, we’ve got a portion there that you can look up for training. We have a curriculum of training courses where they can come and educate themselves, whether it’s, like you say, to learn about what the spec is or maybe take a deeper dive into some of those fields — we have those available. We love talking to our customers and our prospects, too.

One of the things I will mention: In going back to the web as a software service model, one of the things that’s ongoing is the ability to support. We’ve been through so many of these audits and we know the spec probably more than the next guy and when you look at some of the testimonials on our website, you’ll see that they obviously love the product, but they love the ability to call one of us, and if we don’t know the answer, we’ll find out the answer and get them plugged into what they need. We enjoy talking about it.

This year, we’re going to be at the Furnace North America show in Indianapolis which is my hometown which will make it quite easy for me to get there. But we’re going to have a special guest, Doug Shuler, who’s going to be joining us at our booth. So come on by the booth and get all your questions answered by Doug.

DG: If his name is Doug, he can’t be all bad.

Matt, thanks a lot. I really appreciate your time. I’m looking forward to seeing you guys continue to grow and you’re offering a great service to heat treaters, so best of luck to you.

MW: I enjoyed it, Doug, thank you.

DG: You bet.

Two atmosphere controlled retort box furnaces will be used for de-bindering ceramic matrix composite parts (CMC) as well as powder metals processing (PM) and hot isostatic pressing (HIP).

Two atmosphere controlled retort box furnaces will be used for de-bindering ceramic matrix composite parts (CMC) as well as powder metals processing (PM) and hot isostatic pressing (HIP).

DG: I want to jump back onto the labs you were talking about. Very briefly, how many where are they?

DG: I want to jump back onto the labs you were talking about. Very briefly, how many where are they?

MW: Yes, absolutely. Now the tenth of a degree thing, I believe, is going to be extended for another year so that users are going to have one more year for that. The date we’re hearing and looking at is the end of June, so I think June 29th, which I think is the two-year anniversary of Rev E to F, so it will be coming out then, if nothing else changes.

MW: Yes, absolutely. Now the tenth of a degree thing, I believe, is going to be extended for another year so that users are going to have one more year for that. The date we’re hearing and looking at is the end of June, so I think June 29th, which I think is the two-year anniversary of Rev E to F, so it will be coming out then, if nothing else changes.