Manufacturer Adds Endo Generators for Wind Turbine Gearboxes

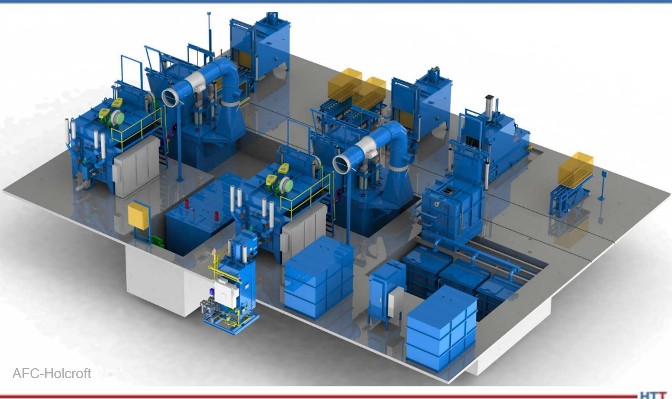

NGC Gears, a manufacturer of wind power gearboxes, has completed the installation of two additional Endothermic generators from a manufacturer with North American locations.

UPC-Marathon, a Nitrex company, installed the Endo generators at NGC Gears‘ its new facility in Jinhu, China. This acquisition brings the total of generator sets to five since 2022, collectively generating an impressive 800 m³/h (22,252 ft3/h) capacity of Endothermic gas supplied to carburizing and hardening furnaces used for processing various gear components. The latest installations in February and March of 2024 support the heat treating operations of the company’s wind energy gearbox production.

NGC’s decision to expand capacity is in response to the growing demand for wind power solutions in China and globally. The new Endothermic gas generating systems will significantly enhance the company’s production capabilities, enabling NGC to meet increasing market needs with greater efficiency and reliability.

EndoFlex offers precise control of production media to the carburizing and hardening environments, leading to higher quality gear production with improved longevity and performance. The result is improved carburizing and hardening processes, higher-quality hardened gears, reduced operating costs, and increased efficiency, as well as immediate cost savings through reduced electricity and gas consumption and minimized waste.

Johnny Xu, general manager at UPC-Marathon China, shared, “The latest EndoFlex investments align with NGC’s development of low-consumption, high-efficiency gearbox products for large-scale onshore and offshore wind turbines.”

This press release is available in its original form here.

Find Heat Treating Products And Services When You Search On Heat Treat Buyers Guide.Com

Manufacturer Adds Endo Generators for Wind Turbine Gearboxes Read More »