Diffusion Bonding Innovation Advancing Aluminum Manufacturing

As this author notes, “Aluminum’s unique blend of lightness, strength, and purity makes it indispensable across various industries.” Especially for aerospace components, bonding aluminum alloy materials to achieve premium structural integrity is essential to keep pace with the demands of new component designs.

In this Technical Tuesday installment, Horst-Gunter Leng, product manager at PVA TePla discusses recent developments in diffusion bonding technology with increased bonding speed of aluminum and aluminum alloys by up to 50%, decreased energy use by 30%, and improved quality.

This informative piece was first released in Heat Treat Today’s February 2025 Air/Atmosphere Furnace Systems print edition.

Background: Aluminum Innovations and Joining

Aluminum, and its broad family of alloys, is prized as a lightweight metal with high purity, strong structural integrity, high electrical and thermal conductivity, corrosion resistance, and a malleability that makes it easy to shape. In aerospace, its high strength-to-weight ratio is crucial for structural components. For semiconductor equipment, aluminum enables the fabrication of intricate, contamination free channels essential for gas and fluid flow, avoiding the impurities inherent in traditional joining methods like brazing or welding.

Many developments in high demand or high quality industrial sectors involve aluminum as one or more of the layers of metals that are bonded. Diffusion bonding is a joining method used to achieve a high-purity interface when two similar or dissimilar metals require superior structural integrity and a traditional brazing approach fails to yield optimum results. The process involves applying high temperature and pressure to metals mated together in a hot press, which causes the atoms on solid metallic surfaces to intersperse and bond, typically (but not exclusively) in vacuum furnaces.

Aluminum’s compatibility with diffusion bonding has allowed for the creation of complex cooling channels in high-power electronics, injection molds, and specialized heat exchangers — designs often impossible to achieve through conventional machining.

Unfortunately, the thermal conductivity characteristics of aluminum present a challenge for the traditional diffusion bonding process, which involves the application of radiant heat into the metal layers while in a vacuum furnace.

This article explores a new bonding technology that overcomes this challenge with a conductive heating method which more rapidly reaches bonding temperature.

Traditional Diffusion Bonding: Challenges with Aluminum

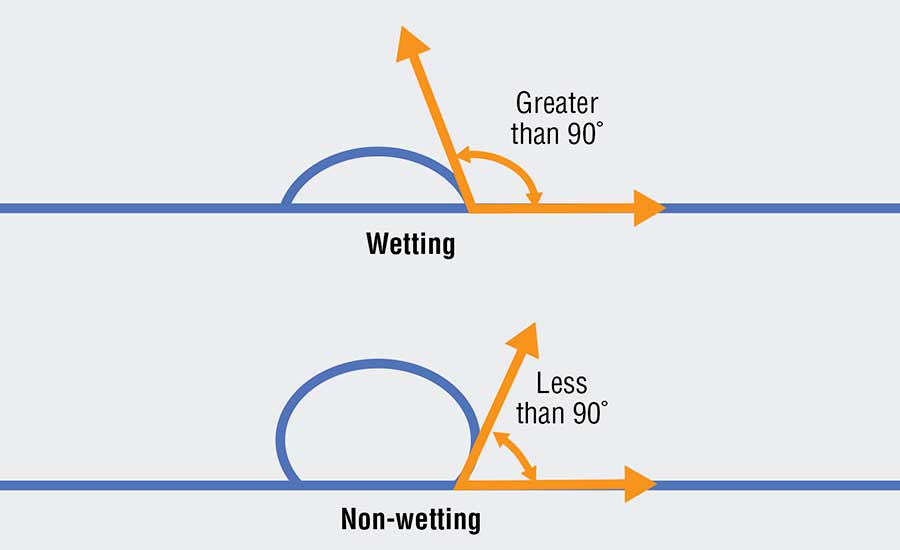

In the traditional diffusion bonding process, a vacuum furnace provides radiant heat to the surface of the part. Subsequently, the heat is conducted through the assembly and transmitted to the faying surface (i.e., surfaces in contact at the joint) where required. Aluminum excels at conducting heat, particularly at lower temperatures, making it ideal for applications requiring efficient heat dissipation, such as in electronics and automotive components. However, when radiation is the dominant form of heat transfer, particularly at relatively lower temperatures in vacuum below 1112°F (600°C), aluminum’s thermal conductivity is time consuming.

Aluminum’s high reflectivity poses a challenge in traditional diffusion bonding. It is like trying to heat a mirror with a spotlight — the energy is reflected away instead of being absorbed into the material using the traditional diffusion bonding process.

Diffusion bonding of aluminum requires superior temperature control throughout the process. To prevent overheating of the load, slow heating rates traditionally are applied, leading to long process times.

In addition, aluminum alloys have a narrow processing temperature range for successful bonding. When temperatures fall outside that critical temperature band, a poor bond is produced.

New Diffusion Solution with Conductive Heating

To overcome the existing challenges of bonding aluminum, a global manufacturer of both industrial furnaces and PulsPlasma nitriding systems alongside its partner initiated an extensive development program. The result was an innovative solution: integrating heating elements directly into the press platens. This approach speeds up the bonding process and significantly reduce enhances efficiency by directly transferring heat to the aluminum components.

The culmination of this research and development is the c.BOND machine. The machine features a combination of direct conduction heating through the top and bottom platens, which are in contact with the assembly. This design ensures bi-directional homogenous heating and more precise temperature at the bonding interface where it is required.

The machine utilizes a hot-press tool with advanced software and feedback sensors to achieve micrometer-precise pressure control across the entire component surface. This ensures uniform bonding over large areas. Furthermore, the system allows for selective heating of specific areas, preventing unnecessary heat exposure to other parts of the component.

The high-vacuum atmosphere within the chamber eliminates contamination and prevents voids in the bonded joint.

With this machine, the time to heat the part to the ideal temperature for bonding is cut in half compared to traditional radiant heating. With less processing time required, the energy requirements are reduced by up to 30% as well. Multilayer stacking is also possible, which can further increase productivity.

With the size of components continually getting smaller in sectors like semiconductors and electronics, controlling the amount of time, and by extension heat, introduced into the part becomes more critical.

Horst-Gunter Leng

The technology demonstrates significant quality improvement of bonded aluminum components. It improves temperature homogeneity in the load by 70%, enhancing bonding across the entire surface. This method also improves the parallelism of parts by 50%, which enhances the accuracy of geometric dimensions, tolerances and product specifications.

As this new machine is commercially available for high-volume production, heat treaters can leverage this furnace technology alongside another unique feature that is incorporated within the system: proprietary automatic bonding software (ABP).

With the automatic bonding software, after parts can be placed in the furnace and a few parameters (such as the size of the bonding area) input, the software automatically calculates the optimum processing parameters. No specific diffusion bonding knowledge from the operator is required. The recipes can be modified according to the type of material being bonded, the thickness of the material, its surfaces and other factors. During the process, the software continuously monitors the process in real time and adjusts parameters accordingly.

Real-World Applications

A unit was installed at a national research facility in Germany, The Günter Köhler Institute for Joining Technology and Materials Testing (ifw Jena), an independent, non-university industrial research institution that conducts research in diffusion bonding, additive manufacturing, brazing, welding, laser processing, material science and other forms of bonding.

The system is compact, requires minimal maintenance, and enables high-volume production of aluminum components for diverse industries. Its benefits are being realized in aerospace, where it creates lightweight yet strong aircraft components. In the semiconductor industry, it provides a cleaner alternative to brazing, eliminating the risk of solder contamination. There is also growing demand for diffusion-bonded aluminum heat sinks, crucial for cooling high-power silicon carbide (SiC) electronics.

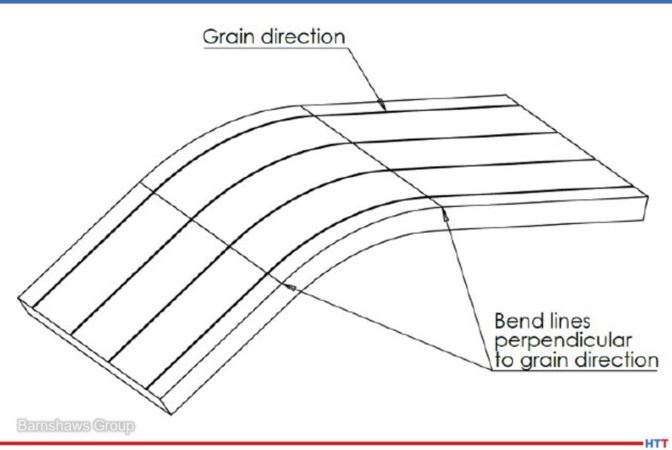

Diffusion bonding also has applications for conformal cooling. The concept is to bond layers of sheet metal that contain machined channel/microchannel structures. When combined, the channels provide a path for heat dissipation. Current applications include power electronics for effective heat management and rapid cooling of molds utilized in injection and blow molding processes.

With the size of components continually getting smaller in sectors like semiconductors and electronics, controlling the amount of time, and by extension heat, introduced into the part becomes more critical.

As the features of the internal channels become more miniaturized, it becomes even more important to control the heating during the diffusion bonding process to avoid any distortion in the part. Shortening the cycle time means introducing less heat into the part. This will facilitate creating parts with conformal cooling channels that have finer and finer features.

As mentioned earlier in this article, diffusion bonding is increasingly valuable for joining dissimilar metals, such as aluminum to steel or titanium. This allows engineers to design components and assemblies with the best properties of each metal. For example, one metal might offer superior corrosion resistance while the other provides greater strength. This “packaging” of dissimilar metals opens up new possibilities in design, particularly for overall weight reduction of design and enhancing performance in challenging environments.

When joining dissimilar surfaces, a liquid-phase diffusion bonding process is utilized, particularly when the bonding interface extends beyond R&D-sized samples. This often involves an interlayer of an alloy that typically melts at the faying surfaces. When the interlayer includes aluminum, the machine can deliver controlled heat to increase the bonding speed.

Conclusion

This new approach to diffusion bonding offers an alternative to the traditional method by circumventing the slow process of radiant heating structural assemblies in a vacuum environment. Although the technology in c.BOND is designed to improve the diffusion bonding of aluminum, it can be modified to the specific needs of the client and customized for the alloy, including copper, an alloy that has many applications in specialized heat exchanger and products used in the microelectronics industry. PVA TePla is exploring options to modify the machine to achieve even higher temperatures above the current maximum of 1472°F (800°C).

As diffusion bonding of aluminum gains importance across industries, contract manufacturers and design engineers must embrace the latest advancements to remain competitive. By adopting fast, energy efficient diffusion bonding technologies for aluminum and other materials, they can unlock higher production volumes, reduce costs, improve or achieve global sustainability targets, and increase profitability.

About the Author:

Product Manager

PVA TePla

Horst-Gunter Leng is the product manager for PVA TePla, a global manufacturer of industrial furnaces and PulsPlasma nitriding systems.

For more information: Contact PVA TePla at www.pvatepla.com/en.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Diffusion Bonding Innovation Advancing Aluminum Manufacturing Read More »