ITPS 2017, International Thermprocess Summit, will be the meeting point for the worldwide heat treating sector on June 27 and 28, 2017 at the InterContinental Hotel in Düsseldorf, Germany. Thermo process technology plays a crucial role in determining the properties of individual products and all industrial manufacturing operations. This is true primarily of the automotive and aviation industries, the glass, ceramics and cement industries, metal production and processing as well as the chemical and petrochemical sector. A number of global challenges need to be dealt with at the same time: the general economic and political conditions around the world, climate protection, carbon footprint, energy and resource efficiency. Friedrich-Georg Kehrer, Global Portfolio Director, Metals and Flow Technologies at Messe Düsseldorf, noted: “This is precisely what the two-day ITPS focuses on, offering the thermo process industry and its stakeholders a customized program. As was already the case at the premiere in 2013 and the subsequent events in India in 2014 and in the U.S. last year, we are again expecting high-level decision-makers to participate.”

The impressive program will start on the morning of the first day with high-profile speakers such as Professor Dr. Ernst Ulrich von Weizsäcker (President of the Club of Rome), Dr. Paul Rübig (Member of the EUParliament), Dr. Christian Kastrop (Director of the Policy Studies Branch in the Economics Department of the OECD) and Eugen Weinberg (Commerzbank). The motto in the afternoon will be “Innovation, digitization, new business models” with the keynote address by Professor Dr. Aldo Ofenheimer (Director Business Development Virtual Vehicle) entitled “Disruptive developments in the mobility industry and their implications for production”. Virtual Vehicle is an international research institute that is based in Graz, Austria, and aims to develop safe, environmentally sound and affordable cars and trains. The other presenters will be Dr.-Ing. Gunther Kegel (CEO Pepperl+ Fuchs) and Dr. Richard Mark Soley (Industrial Internet Consortium). Both of their presentations will focus on the Internet and the impact and opportunities of digitization on industry. “The Internet has not changed everything – the industrial community continues to refuse to apply Internet technologies,” stated Dr. Richard Mark Soley.

“I am delighted that we have succeeded in creating another highly interesting program that will deal not only with scientific and practical aspects but also with the general global, economic and industry policy conditions,” noted Dr. Timo Würz, VDMA Metallurgy Director and member of the program advisory board. The second day will be devoted to “best cases” in the key automotive, aviation and machine manufacturing sectors. The complete program is expected to be published in March 2017 when tickets for the ITPS 2017 will also be available (cost: Euro 950). For the latest information visit www.itps-online.com.

The second feature of the Thermprocess Summit will be the exhibition in the foyer of the InterContinental Hotel, where conference participants can get information on state-of-the-art technologies during the breaks. Companies can book 6 or 12 square meter stands or book sponsor packages. Contact Jennifer Dübelt (e-mail: DuebeltJe@messe-duesseldorf.de; (Tel.: +49211-4560520) for application forms.

ITPS & The Bright World of Metals

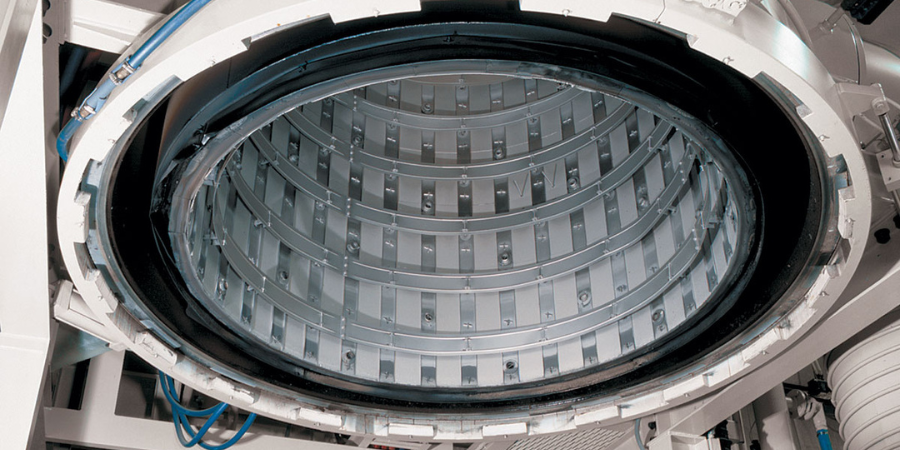

Three years ago, Messe Düsseldorf, the VDMA foundry machines association (Germany), the European thermo process association CECOF (European Committee of Industrial Furnace, the Heating Equipment Association (Germany) and the trade magazine “Heat Processing” published by Vulkan-Verlag in Germany launched the ITPS conference and exhibition with great success. In 2013, the conference participants came from 16 different countries from all over the world. Every two years, Düsseldorf becomes the hotspot for the global thermo process industry and the industries that use its products – with ITPS and THERMPROCESS taking place alternately. The four international technology trade fairs GIFA (International Foundry Trade Fair), METEC (International Metallurgical Trade Fair), THERMPROCESS (International Trade Fair for Thermo Process Technology) and NEWCAST (International Trade Fair for Castings) will be held in 14 halls from June 25 – 29, 2019 at the fairgrounds in Düsseldorf, Germany. More than 2,000 exhibitors and about 78,000 are expected to attend. International stakeholders in the castings, foundry technology, metallurgy and thermo process technology sectors will meet in Düsseldorf, Germany for five days. A first-rate program will complement the trade fairs consisting of seminars, international congresses and a lecture series. Further information is available at www.gifa.com, www.metec-tradefair.com, www.thermprocess-online.com, www.newcast.com, and www.tbwom.com.

For further information about ITPS 2017, contact Messe Düsseldorf North America, 150 North Michigan Avenue, Suite 2920, Chicago, IL 60601. Telephone: (312) 781-5180; Fax: (312) 781-5188; E-mail: info@mdna.com; Visit our web sites www.itps-online.com , www.tbwom.com and http://www.mdna.com;

Twitter: www.twitter.com/tbwom Facebook: http://www.facebook.com/TheBrightWorldofMetals

LinkedIn: http://www.linkedin.com/groups/7442674