Motorcycle Manufacturer Embarks on Sustainable Heat Treat Future

Guangdong Tayo Motorcycle Technology Co. Ltd., a Chinese manufacturer of motorcycles and bicycles, has invested in a nitriding/nitrocarburizing system, increasing sustainability and growth for its new production facility in Jiangmen City, located in southern China’s Guangdong province.

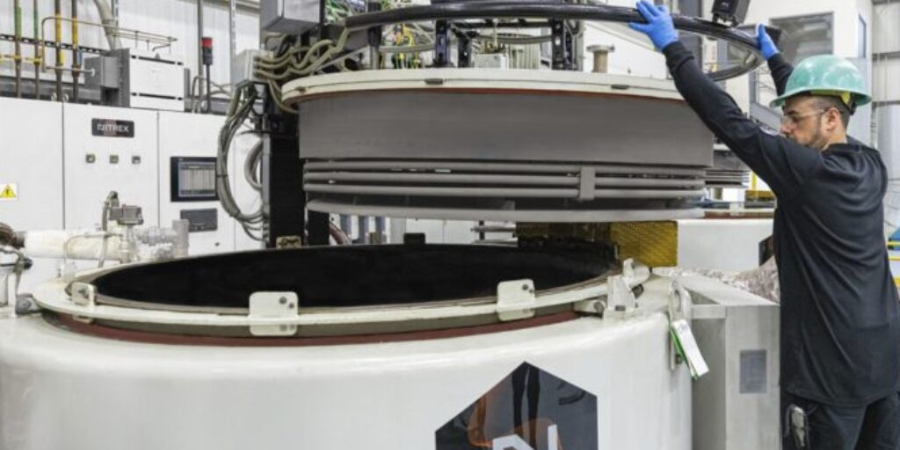

Heat treat solutions company Nitrex was commissioned to deliver a comprehensive turnkey system, geared towards enhancing the performance and durability of multiple components within Guangdong Tayo Motorcycle, including those for the brands Haojiang, Daye, Shengshi, and Qidian.

Nitrex Regional Manager – Asia

Source: NITREX

Nikola Dzepina, Nitrex account executive, said, “Our partnership with Guangdong Tayo Motorcycle Technology Co. Ltd. will help them in fulfilling their mission of delivering top-notch, highly durable, and reliable motorcycles and bicycles to their global customer base.”

As part of their development strategy, Guangdong Tayo Motorcycle has placed sustainability, product quality, service excellence, and market expansion at the heart of their mission. Paving the way for superior motorcycles and bicycles, the company evaluated various options and ultimately selected Nitrex for its precision-controlled processes, process stability and repeatability, equipment longevity and reliability, and commitment to environmental friendliness.

Source: Nitrex

The turnkey system comprises a large pit-type furnace, model NX-1225, with a 4000-kg load capacity and the Nitreg® controlled nitriding and Nitreg®-C nitrocarburizing technologies. These surface treatments augment the properties of motorcycle and bicycle metal components, significantly enhancing wear resistance and providing protection against rust and corrosion. Additionally, the system features an ammonia dryer and accelerated cooling system, facilitating the delivery of high-purity ammonia and fast cycle times to optimize production efficiency.

Tao Liu, sales manager at Nitrex China, emphasized, “This system’s exceptional reliability, engineered for longevity with minimal maintenance requirements and low utility and production media consumption costs, aligns perfectly with Guangdong Tayo Motorcycle’s vision for a sustainable future.”

This press release is available in its original form here.

Find Heat Treating Products and Services When You Search on Heat Treat Buyers Guide.com

Motorcycle Manufacturer Embarks on Sustainable Heat Treat Future Read More »