2 “Heavy Duty” Furnaces Expand Tempering Capabilities for Ohio Heat Treater

Twin convection furnace systems were recently supplied to Winston Heat Treating. The furnaces replaced two older tempering systems. The new systems are for ferrous alloys and aging PH stainless steels.

President at Winston Heat Treating

Source: LinkedIn

The SCAHT®-HD (Heavy Duty) Series furnaces, from DELTA H®, are set up with Instrumentation Type B and have two load thermocouples. The furnaces have a certified TUS volume of 2 feet wide, 1.5 feet high and 2 feet deep with a maximum continuous operating temperature of 1,200°F. Both are designed to receive baskets of parts from many nearby heat treating operations for secondary heat treatments. Temperature control and data acquisition are provided by Super Systems and feature the SSi 9130 controller/programmer. ATP qualified them as Class 2 (+/- 10°F) from 300°F to 1200°F.

“We were looking for a partner to replace existing tempering furnaces that had become too costly to maintain and could no longer meet required pyrometry standards. Our goal was to install reliable and modern furnaces that were specialized for our small batch/job shop work," said David Reger, president at Winston Heat Treating and a Heat Treat Today's 40 Under 40 recipient.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

2 “Heavy Duty” Furnaces Expand Tempering Capabilities for Ohio Heat Treater Read More »

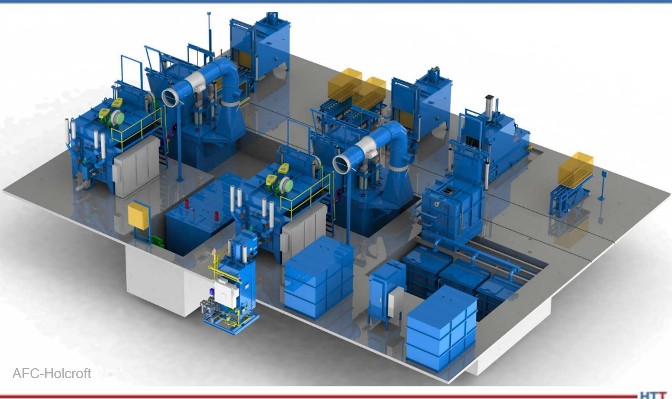

A southeastern U.S. manufacturer will receive a dual-chamber heat treating and tempering furnace. The recipient, a leading manufacturer of shopping carts and display cases, will be using the furnace to thermally process various projects.

A southeastern U.S. manufacturer will receive a dual-chamber heat treating and tempering furnace. The recipient, a leading manufacturer of shopping carts and display cases, will be using the furnace to thermally process various projects.