2 Large Scale Furnaces for Automotive and Marine Propulsion

Two intensive furnace projects are poised to bring heat treating to the automotive brake rotor and marine propulsion systems industries. An FNC furnace has been completed which will process approximately 600,000 brake rotors per year for the automotive industry. An additional pit nitriding furnace has a capacity of 40,000 lbs and will be utilized for the production of large marine gears.

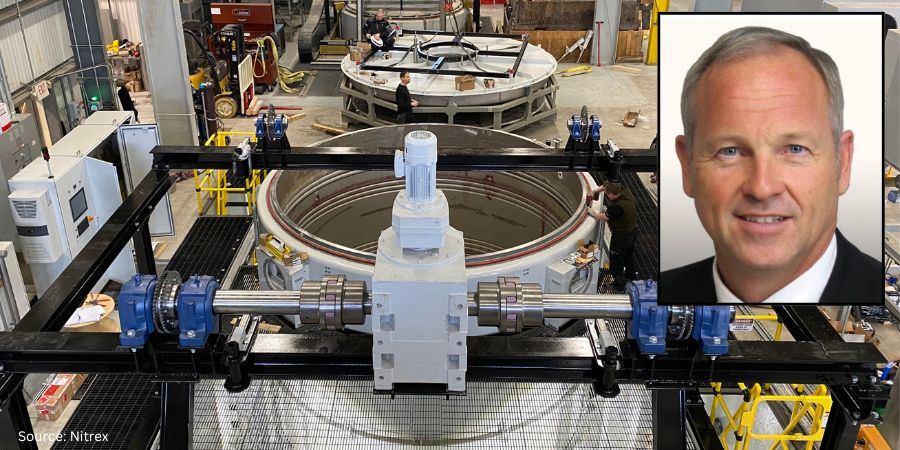

Brake Rotor Furnace

President

Nitrex/UPC-Marathon

Source: Linkedin

“In August our Team received Final Acceptance on two of the most difficult projects in Nitrex history…Our most sophisticated brake rotor semi-continuous FNC furnace is installed at a subsidiary of a major auto maker in Europe. Again, our team worked tirelessly to meet customer demands. I am so proud of our team and what they accomplished,” remarked Mark Hemsath, president of Nitrex/UPC Marathon.

The scale of the brake rotor furnace highlights its uniqueness. The furnace processes approximately 600,000 rotors per year, or about 1.6 metric tons per hour. If run continuously, output could approach nearly a million rotors annually.

The brake rotor furnace integrates a post-oxidation (ONC®) process, allowing control over both the color and oxide layer. This feature sets it apart from furnaces currently in use for brake rotors.

The standard load size of the brake rotor furnace is: 1200 mm x 1200 mm x 1800 mm, with a gross load capacity of up to 4 metric tons. Nitrex was able to offer an extended charge size to 2400 mm deep, which could raise throughput to about 2 metric tons per hour.

Source: Nitrex

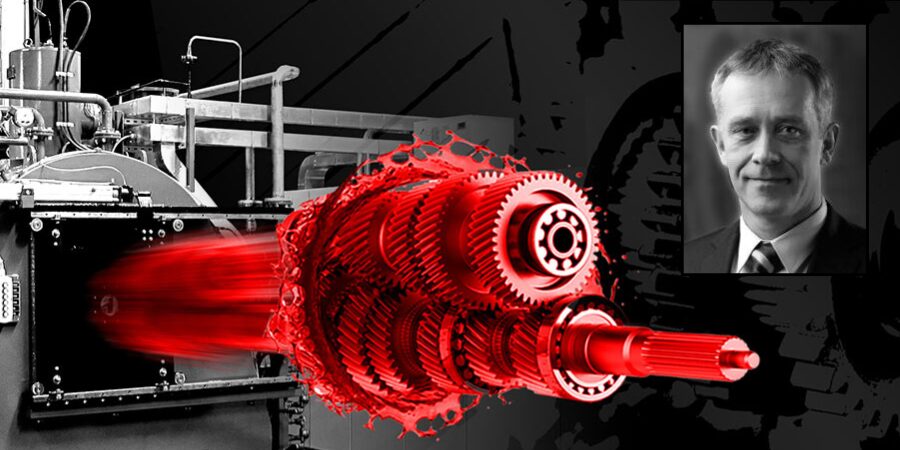

Pit Furnace

Source: Nitrex

The pit furnace represented another leap forward with a capacity of 40,000 lbs. — double the weight of Nitrex’s standard largest pit furnace. Engineering efforts centered on maximizing productivity while maintaining the precision nitrided layers expected from smaller systems.

This furnace presented significant logistical challenges due to its sheer size and complexity in transport and installation.

Mark Hemsath remarked: “I am so proud of the effort our entire team exerted to meet schedules, quality demands and design improvements. Our largest ever precision Nitrider (4.5 meter diameter!) for deep-case nitriding of large gears was built on-site with no prior testing.”

The pit furnace is built to handle extremely large gears, typically for marine propulsion systems in very large ships where double-helix gears are standard. These gears, which can weigh 20,000 lbs, require 12 days to nitride, not including heating or cooling — a stark contrast to the two-hour cycle time of the semi-continuous rotor furnace, which is for high volumes in automotive settings.

The furnace stands at 4.5 meters (177 inches / 14.75 feet) in diameter and 3.5 meters deep (11.48 feet), marking one of the largest precision nitriding capacities ever built with a retort lining.

Project Highlights

These projects were collaborative, drawing expertise from across the organization.

In Canada, Janusz Szymborski came out of retirement to contribute design enhancements. Lead Designer Kamil Szczudlo and Chief Engineer Marcin Doroszko from Nitrex’s Poland facility drove the design, automation, and gas flow systems, while plant manager Robert Sokolinski coordinated production and logistics. Karl Michael Winter, vice president of Engineering in Germany, worked on advanced brake rotor layer formation.

Heat Treat Today original press release, last updated on 09/10/2025 at 6:04am.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

2 Large Scale Furnaces for Automotive and Marine Propulsion Read More »