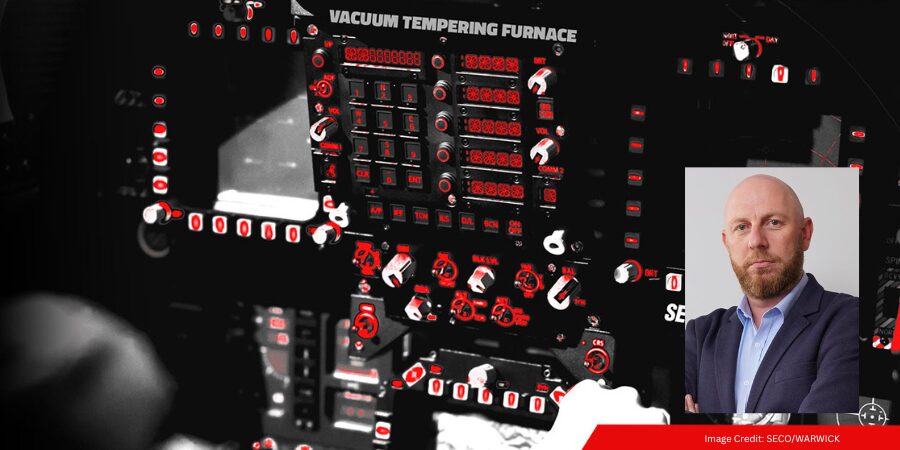

Vacuum Tempering Furnace Strengthens Aerospace Capacity

An international aircraft motion-control manufacturer is expanding its heat treat process capacity by ordering an additional low-temperature vacuum tempering furnace to support tempering, ageing, and other sub-critical heat treating of precision components. The equipment will be used to maintain consistent thermal processing standards for aerospace applications.

The repeat order will be supplied by SECO/WARWICK‘s U.S. subsidiary. The furnace is a low-temperature vacuum tempering unit capable of operating up to 1380°F (750°C) within a 24 × 24 × 36 in (600 × 600 × 900 mm) work zone and supports a 1750-lb (~800 kg) load capacity. Designed to meet AMS2750F Class 2 temperature-uniformity-survey (TUS) requirements (±10°F/±5.6°C), it uses nitrogen convection for both heating and cooling, with final cooling provided by an internal recirculation blower and water-cooled heat exchanger for stable, efficient cycles.

Managing Director

SECO/WARWICK USA

This additional furnace joins an existing suite of heat treat equipment at the manufacturer’s facilities, which already includes multi-chamber CaseMaster Evolution models and a Vector single-chamber high-pressure gas-quench vacuum furnace from SECO/WARWICK. These installations reflect long-standing collaboration on thermal processing solutions for aerospace components.

According to Piotr Zawistowski, managing director of SECO/WARWICK USA, the ongoing investments by this aerospace partner reflect confidence in the technical expertise and support provided by SECO/WARWICK and the performance consistency of its vacuum tempering solutions.

Press release is available in its original form here.

Vacuum Tempering Furnace Strengthens Aerospace Capacity Read More »