Nitriding System To Bring Heat Treat In-House

The Lenox Group, an aluminum extrusion profiles company, decided to add a turnkey nitriding system from a supplier with North American locations. The new heat treat furnace will further aid in production of products like windows, doors, solar panels, lighting systems, etc.

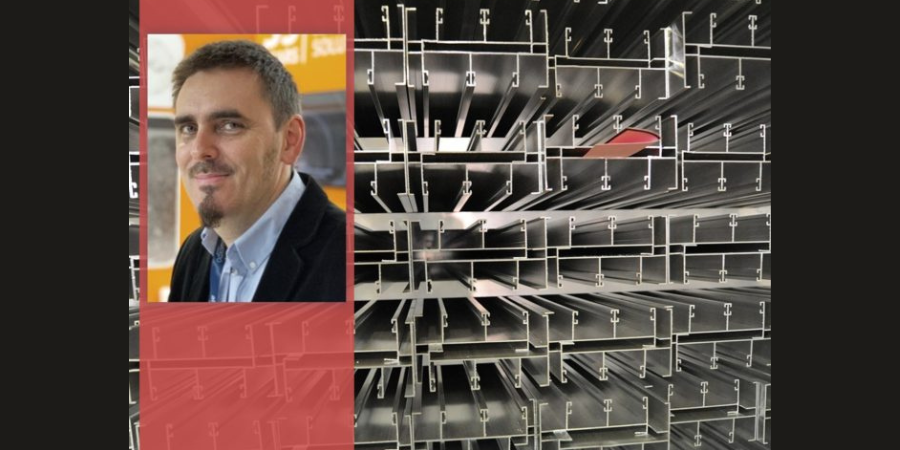

The Lenox Group, an aluminum extrusion profiles company, decided to add a turnkey nitriding system from a supplier with North American locations. The new heat treat furnace will further aid in production of products like windows, doors, solar panels, lighting systems, etc.

Project Manager

Nitrex Poland

LinkedIn.com

Lenox has opted to bring operations in-house (in Bulgaria) to improve die reliability through more stringent quality control. “Previously, the company sent extrusion dies for salt bath nitriding and gas nitriding," explains Marcin Stokłosa, project manager at Nitrex. "Lenox Group experimented with various case hardening technologies in search of the best one, the results of which would be repeatable and consistent with their expectations."

The N-EXT 412 is a compact-size Nitrex gas nitriding furnace for low volume quantities. This turnkey nitriding system is built on a self-contained platform that includes the furnace, control system with Nitreg® technology, and an exhaust neutralizer for clean and green processing. With a temperature distribution of +/-5°C, it is suitable for nitriding H11 and H13 extrusion dies.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Nitriding System To Bring Heat Treat In-House Read More »