August 2024: Annual Automotive Heat Treating and Furnaces North America (FNA) Pre-Show Issue

Thinking about travel plans for the upcoming holiday season? You may know what means of transportation you will be using, but perhaps you haven't considered the heat treating processes which have gone into creating that transportation.

Today’s Technical Tuesday original content round-up features several articles from Heat Treat Today on the processes, requirements, and tools to keep planes in the air and vehicles on the road, and to get you from one place to the next.

Without standards for how furnaces should operate in the aerospace, there could be no guarantee for quality aerospace components. And without quality aerospace components, there is no guarantee that the plane you're in will be able to get you off the ground, stay in the air, and then land you safely at your destination.

In this article, written by Douglas Shuler, the owner and lead auditor at Pyro Consulting LLC, explore AMS2750, the specification that covers pyrometric requirements for equipment used for the thermal processing of metallic materials, and more specifically, AMEC (Aerospace Metals Engineering Committee).

This article reviews the furnace classes and instrument accuracy requirements behind the furnaces, as well as information necessary for the aerospace heat treater.

See the full article here: Furnace Classifications and How They Relate to AMS2750

Curious to know how the components of an aircraft are assessed and reproduced? Such knowledge will give you assurance that you can keep flying safely and know that you're in good hands. The process of dissecting an aircraft, known as reverse engineering, can provide insights into the reproduction of an aerospace component, as well as a detailed look into the just what goes into each specific aircraft part.

This article, written by Jonathan McKay, heat treat manager at Thomas Instrument, examines the process, essential steps, and considerations when conducting the reverse engineering process.

See the full article here: Reverse Engineering Aerospace Components: The Thought Process and Challenges

If you are one of the growing group of North Americans driving an electric vehicle, you may be wondering how - and how well - the components of your vehicle are produced. Electric vehicles (EVs) are on the rise, and the automotive heat treating world is on the lookout for ways to meet the demand efficiently and cost effectively. One potential solution is laser heat treating.

Explore this innovative technology in this article composed by Aravind Jonnalagadda (AJ), CTO and co-founder of Synergy Additive Manufacturing LLC. This article offers helpful information on the acceleration of EV dies, possible heat treatable materials, and the process of laser heat treating itself. Read more to assess the current state of laser heat treating, as well as the future potential of this innovative technology.

See the full article here: Laser Heat Treating of Dies for Electric Vehicles

Reliable and repeatable heat treatment of automotive parts. Without these two principles, it’s hard to guarantee that a minivan’s heat treated engine components will carry the family to grandma’s house this Thanksgiving as usual. Steve Offley rightly asserts that regardless of heat treat method, "the product material [must achieve] the required temperature, time, and processing atmosphere to achieve the desired metallurgical transitions (internal microstructure) to give the product the material properties to perform it’s intended function."

TUS surveys and CQI-9 regulations guide this process, though this is particularly tricky in cases like continuous furnace operations or in carburizing operations. But perhaps, by leveraging automation and thru-process product temperature profiling, data collection and processing can become more seamless, allowing you better control of your auto parts. Explore case studies that apply these two new methods for heat treaters in this article.

See the full article here: Discover the DNA of Automotive Heat Treat: Thru-Process Temperature Monitoring

Traveling through Heat Treat: Best Practices for Aero and Auto Read More »

Two new furnaces are about to go live for Wallwork Group Ltd. These furnaces will increase the heat treating capacity within the group and help the demand for the aerospace and general engineering industries.

These furnaces from SECO/WARWICK, an international industrial furnace company with North American locations, are capable of 10bar pressure quench and designed to deal with increasingly detailed customer specifications. Joining Wallwork Group's current heat treat capacity, consisting of sealed quench, plasma and gas nitride, vac braze, salt nitrocarburize, PVD coatings, and a hot isostatic pressing center, these new furnaces will further expand heat treating potential for aerospace and general engineering.

Two New Furnaces for Industrial Machining Manufacturer Read More »

Heat Treat Today publishes eight print magazines a year, and included in each is a letter from the publisher, Doug Glenn. This letter first appeared in September's 2023 People of Heat Treat print edition.

Feel free to contact Doug at doug@heattreattoday.com if you have a question or comment.

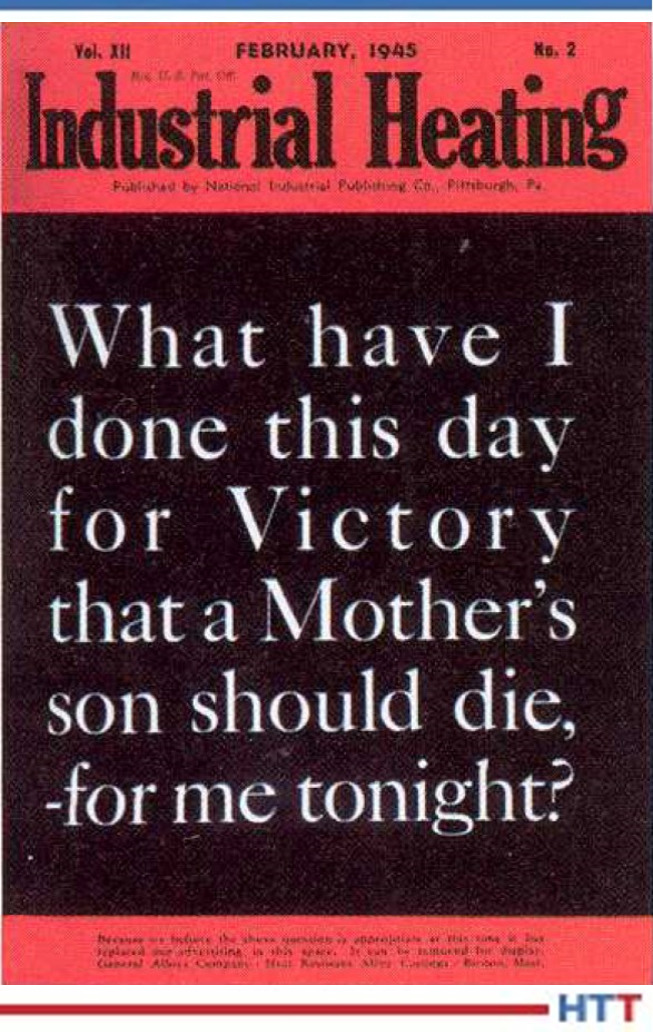

BNP Media, once the largest privately- owned industrial publishing company in the U.S., announced recently they are closing down the legendary heat treat industry magazine, Industrial Heating, effective August 31, 2023.

Some might think this news would be a source of joy in the Heat Treat Today camp, since it is the elimination of a competitive publication. But I can tell you that it is crushing news — crushing for me, personally, having spent 20 tremendous years as the publisher of Industrial Heating from 1994 to 2013, and crushing for the North American thermal processing industry, because a nearly 100-year old iconic magazine no longer exists.

Someone needs to sing the praises and acknowledge the greatness of what was Industrial Heating, so here we go.

In 1924, in the heart of steel city Pittsburgh, Pennsylvania, a gentleman by the name of Stanley Wishoski started Fuels and Furnaces to meet the information needs of the budding steel industry. Fuels and Furnaces was published under that name for seven years and was then rebranded as Industrial Heating in 1931. The publication stayed in the Wishoski family for 64 years, being run much of the time under the direction of Chuck McClelland, son-in-law of Stan Wishoski. Some of you old timers might remember Chuck McClelland or Industrial Heating’s long time editor Stan Lasday. In August of 1988, Business News Publishing Company (now BNP Media) purchased the magazine from Chuck McClelland.

In 1988, Industrial Heating was the number two magazine in the industry behind a publication called Heat Treating, which was at one time owned by Chilton Publishing Company, a company that was, I believe, part of ABC (American Broadcasting Co.). Dave Lurie of Business News Publishing Company saw to it that Industrial Heating grew into the number one spot in the industry in short order. By the mid-1990s, Industrial Heating was the leader.

All through the 1990s and well into the 2010s, Industrial Heating was the kingpin of the North American heat treat industry. During this span, Industrial Heating started Industrial Heating Brazil, Industrial Heating China, and even Industrial Heating India. FORGE magazine, which also closed this August, was founded during this time.

Furnaces North America (FNA) was started by Industrial Heating in 1995. The Metal Treating Institute helped by providing the technical content for the event. Industrial Heating owned and produced FNA ’95 (Cleveland, OH), FNA ’96 (Dearborn, MI), and FNA ’98 (Las Vegas, NV). Then, we sold it to the Metal Treating Institute for $1.00 and an (undisclosed!) percentage of revenue for the next seven events.

For two to three years, Industrial Heating even cooperated with ASM International to publish what is today known as HTPro eNews. The magazine also made the transition from an all-print publishing world to a digital and print publishing world — at least initially. No small feat.

One of the magazine’s most successful products was its annual Buyers Guide, which (just to give you a sense of how successful) often brought in more than $500,000 in ONE MONTH. Annual revenues were in the millions, and profit margins were impressively high. The magazine was enormously successful.

What made Industrial Heating so successful was the people working there. During its heyday, the real “secret” behind the success was people like Jim Henderson, owner and president of Business News Publishing at the time; Dave Lurie, one of the best bosses I’ve ever had and a natural born leader; Kathy Pisano, see my Publisher’s Page about Kathy in Heat Treat Today’s August 2022 Automotive edition; Reed Miller, one of the best and longest-tenured editors the magazine ever had; Bill Mayer, a hard-charging, talented editor; Becky McClelland and Beth McClelland, both granddaughters of Stan Wishoski and daughters of Chuck McClelland; Brent Miller, who had no relation to Reed Miller, but was an outstanding graphic artist; Ed Shaud, father of the actor Grant Shaud from Murphy Brown fame; and Ed Kubel, of ASM fame. Mike Holmes, Kristine Haben, Dick Schiffman, Larry Pullman, Steve Roth, Susan Heinauer, Patrick Connolly, Keith Patrick, and the dozens of administrative and support staff at BNP Media headquarters in Troy, Michigan were also part of this outstanding team. It was this group and their unwavering focus on innovation and on what was best for the customer that made Industrial Heating a powerhouse . . . revenues and profits followed.

In fact, at its peak, Industrial Heating was one of the three largest revenue producers at BNP Media. When I left Industrial Heating at the end of September 2013, it was indisputably the 800-pound gorilla in the North American heat treat industry. Ten years later, it is closing down. Theories about Industrial Heating’s closing are many. Whatever the reason, it is more important to recognize the publication for its dominant place in the North American heat treat market and for its nearly 100 years of existence. Thank you, Industrial Heating and the people who worked there, for the decades of excellent content curation. You truly are “The International Journal of Thermal Processing.” The industry is worse off today than yesterday. It is a sad day.

Letter from the Publisher: In Praise of Industrial Heating Read More »