![]() What is the connection between AMS2750 specifications and furnace classifications? With tight specifications, what does the heat treater need to know to be compliant? Follow along as we take a brief look into this often-overlooked topic.

What is the connection between AMS2750 specifications and furnace classifications? With tight specifications, what does the heat treater need to know to be compliant? Follow along as we take a brief look into this often-overlooked topic.

This Technical Tuesday article, written by Douglas Shuler, owner and lead auditor, Pyro Consulting LLC, was first published in Heat Treat Today's March 2023 Aerospace Heat Treating print edition.

Lead Auditor

Pyro Consulting

AMS2750 is the specification that covers pyrometric requirements for equipment used for the thermal processing of metallic materials. AMEC (Aerospace Metals Engineering Committee) is one of the committees which oversees the changes and revisions of AMS2750. There are five main sections in the technical requirements of the specification: sensors, instrument calibrations, thermal processing classification, SAT (system accuracy testing), and TUS (temperature uniformity surveys). Additionally, there are quality provisions that detail what happens if a calibration or test is either past due or fails.1

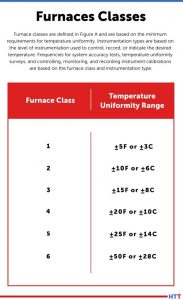

Revisions to the original requirements have occurred over the years, with the newest being Revision G. The structure of Revision G has carried over from Revision F and has remained the current structure of the AMS2750 specification. This structure includes furnace classes, which are based on the minimum requirements for temperature uniformity.

Furnace classes are defined in Figure A of Revision D Figure 1.

Source: Doug Shuler

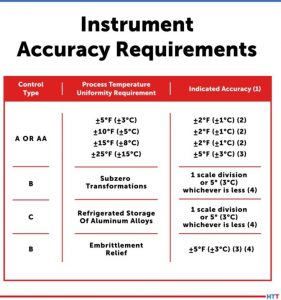

Originally, furnace classes were based on temperature uniformity, but also subzero transformation, refrigerated storage of aluminum alloys, and embrittlement relief, Figure 2.

Source: Doug Shuler

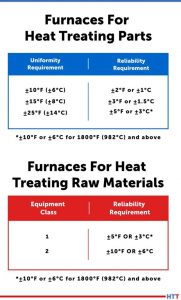

AMS2750 Revision C was released in May 1990 and started to implement the class and instrumentation type structure and differentiated between furnaces for heat treating parts versus furnaces for heat treating raw materials. Furnaces for heat treating parts were classified based on uniformity, but also on a readability requirement. Furnaces for heat treating raw materials were classified based on a readability requirement alone.

AMS2750 Revision D was released in September 2005 and continued to define equipment class (Figure A)* and instrumentation type (Section 3.3.1.1)*. It also clarified chart recorder resolution (Table 4)*, print and chart speed (Table 5)*, and testing frequencies for SAT (Tables 6, 7)* and TUS (Tables 8, 9)* for the processing of parts versus raw materials.

AMS2750 Revision E was released in July 2012 and continued to build on the clarity presented in Revision D by adding an instrumentation type table (Figure 3)* instead of a simple text description in the body of the specification.

Source: Doug Shuler

Moving to AMS2750 Revision F, the specification saw a major rewrite and restructuring where the tables were moved from the end of the document to the first area text that called out the specific table. Revision F also put into place a sunset date for analog instruments.

That brings us to the current revision of AMS2750, Revision G, which has carried forward the structure of Revision F and only sought to further clarify the intent of the requirements.

Over the years, the technology of sensor, instrument, and furnace manufacture and capability has continued to produce better and tighter controls for the process of heat treating. The evolution of AMS2750 has recognized these advancements and has kept pace with them in technology. The understanding of the origins of AMS2750 and how it has evolved is vital in understanding its application to today’s heat treat special processes.

*Specified figure, table, or section is associated with the AMS2750 revision being discussed.

References

1Andrew Bassett. “Heat Treat Radio #38: Andrew Bassett on AMS2750F (Part 1 of 3)”

https://www.heattreattoday.com/media-category/heat-treat-radio/heat-treat-radio-andrew-bassett-on-ams2750f/.

About the Author: In 2009, Douglas (Doug) Shuler became the owner of Pyro Consulting LLC and also began working with Performance Review Institute (PRI), first as an instructor and course developer and later as an auditor for the Nadcap program. As a lead auditor for Nadcap, he has conducted over 380 Nadcap special process and aerospace quality management system audits on behalf of the Aerospace Primes over the past 10+ years. Doug continues to focus on instruction, training, and education for the heat treat industry, developing courses, authoring exams, and employing the PIE method: “Procedures that Include all requirements, and Evidence to show compliance.”

For more information: Contact Doug at dgshuler@pyroconsulting.net