Source: Advanced Heat Treat Corp. Blog

Source: Advanced Heat Treat Corp. Blog

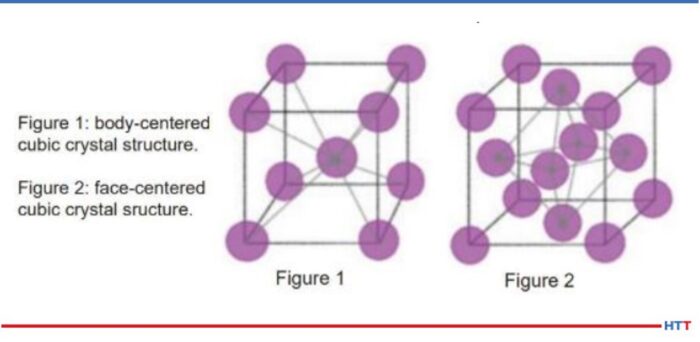

For this Heat Treat Today Technical Tuesday, check out this Best of the Web primer if you are looking to share a few basic pieces of heat treat info with your trainees. These heat treat fundamentals are about what happens to metals in the heat treatment process, tracing steel heat treating back to the ancient Romans in 223 B.C. — though, Encyclopedia Britannica currently places the origins in Egypt by 900 BC. Heat treatment benefits, atomic structural transformation, and hardenability are all covered here.

An excerpt: “Not every steel reacts the same. Chemical composition can vary greatly between the different grades of steel. Certain alloying elements can greatly increase the hardenability of steels such as nickel (Ni), chromium (Cr) and molybdenum (Mo). Hardenability is not how hard a material is. Hardenability directly relates to the ability of a metal to form martensite and martensistic [sic.] structure upon quenching, which points to…”

Read more: “What’s Happening to Metals During Heat Treatment”