Cost of Fuel Drives Change

Jim Roberts of U.S. Ignition engages readers in a Combustion Corner editorial about how rising fuel costs have driven dramatic improvements in furnace efficiency and combustion technology over the past 60 years, transforming heat treat processes from 20% to 70% fuel efficiency.

This editorial was first released in Heat Treat Today’s January 2026 Annual Technologies to Watch print edition.

A furnace guy walks into the shop and sees the cost of gasoline. “This keeps going up, what gives?”

My first car got about 10 MPG — we will not even go near to discussing when that was. Gasoline costs have since driven cars to become more efficient with 30+ MPG vehicles.

Last month’s article highlighted how there are five qualities in our heat treat processes: Quality and Accuracy, the necessary attributes; Efficiency and Performance, the variables; and Profit, which comes whenever we improve the two variables. We have discussed government regulation on emissions and technological breakthroughs that improved combustion technology in earlier articles, but now we turn to the connection of combustion and cost: how gasoline costs drove improvement of the two variable qualities of heat treat processing for combustion, Efficiency and Performance.

Gasoline Costs: A Timeline

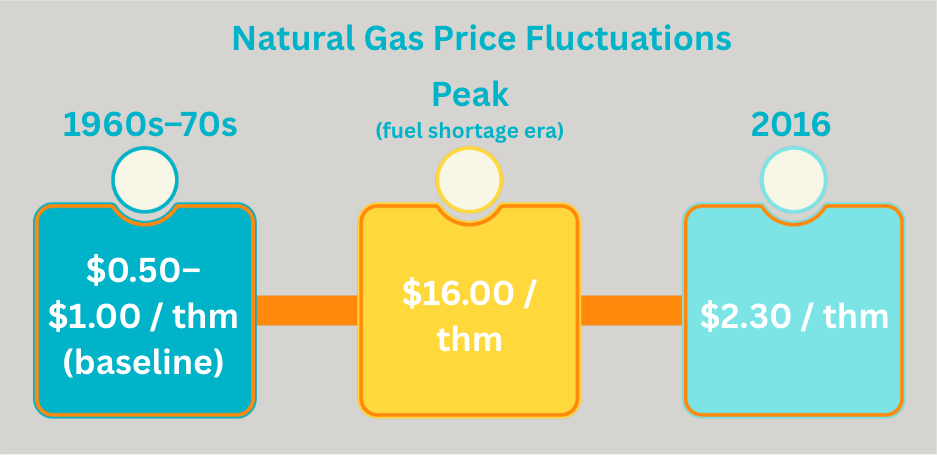

Up until about 1960, the world of heat processing was pretty much a level playing field with Efficiency and Performance. We had tons of fuel at our disposal. Pollution was known but not yet a criterion to manage processes. So, burner efficiency and design were very low end. Nobody cared. Fuel was almost free. In doing research for this story, I found records of natural gas being less than $0.50 per million BTUs. Electricity was on par with delivered BTU costs. But then the cost of fuel started to fluctuate. The furnace guys started to notice; if nothing else changed, our friend Profit would weaken.

From 1930 to 1980, electricity pricing went up 500%. Natural gas started to bounce around in price. It was less than a $1.00/thm in the ’60s and ’70s, peaking during times of fuel shortage at $16.00/thm. Ten years later, in 2016, it hit $2.30/thm again. Some pretty wild fluctuations. In fact, it should be noted that the industry overseas had already begun to shift technologies — several years ahead of the U.S. — because they had been suffering with high fuel costs in Great Britain, Germany, Western Europe, and in Asian markets.

Furnace guy and the suppliers had to improve the efficiency and performance.

Troubleshooting and Combustion Design Changes

At first, you look at easy fixes to improve Efficiency and Performance. An example would be that insulation and refractory science really improved. If you can keep the heat in the furnace, you need less fuel to hold it at these high temperatures, right? So, improve the insulation.

Next, let’s get the burners from just being the opening in the furnace that you pour gas into, and make the burner more like a carburetor on an engine. Let’s get control of the air and gas ratios.

Next, let’s recover some of the flue gases and pre-heat the air coming into the burner. When you do that, the flame temp goes up, sometimes by as much as 400-500°F. That means higher heat transfer rates to the parts inside a now well-insulated furnace. Huge efficiency gains started happening.

Efficiency and Performance got a huge boost when the burners started to have high velocity discharge rates. In other words, we now had flames that were hotter and going into the furnace at several hundred miles an hour more than before. With that comes circulation improvement inside the furnace. And much like pudding in a blender, the faster the beaters, the smoother the mix. To give you an idea of the scope of these improvements, form 1960 to 1990, a matter of only 30 years, furnace and burner technology improvements went from 20% fuel utilization to estimated 60-70% fuel efficiencies, even higher in some instances. And there it was, super efficiency driven to occur by fuel cost and flucturation of supply.

To really hit home what that meant, let’s look at a 1,000-lb load of steel. Our process temp is 1750°F. Our furnace and combustion efficiency used to be 20%. That would require 1,370,000 BTU to heat up in an hour. Now, with 75% furnace and burner efficiency, that’s 352,000 BTU. You just saved approximately 1,000 ft3 of gas per hour! If we use the average industrial gas price today at $3.80/1,000 ft3, the difference of all this is $24,000/year, and that’s just a 1,000-lb load. Real world, the numbers are significantly higher, as all you furnace guys know. Imagine the dollar savings when fuel was at $16.00/thm?

And so, there it is. The well-known realization that in most markets, the dollar cost of the energy triggers improvement of technology.

Until next time…

About The Author:

President

US Ignition

Jim Roberts president at U.S. Ignition, began his 45-year career in the burner and heat recovery industry focused on heat treating specifically in 1979. He worked for and helped start up WB Combustion in Hales Corners, Wisconsin. In 1985 he joined Eclipse Engineering in Rockford, IL, specializing in heat treating-related combustion equipment/burners. Inducted into the American Gas Association’s Hall of Flame for service in training gas company field managers, Jim is a former president of MTI and has contributed to countless seminars on fuel reduction and combustion-related practices.

For more information: Contact Jim Roberts at jim@usignition.com.

Cost of Fuel Drives Change Read More »