A leading component supplier to manufacturers of converting and CNC machinery, Reymak Makine As, has embarked on a journey to enhance manufacturing quality while reducing its environmental impact. This strategic move aims to internalize heat-treating operations and advance the sustainability tooling components.

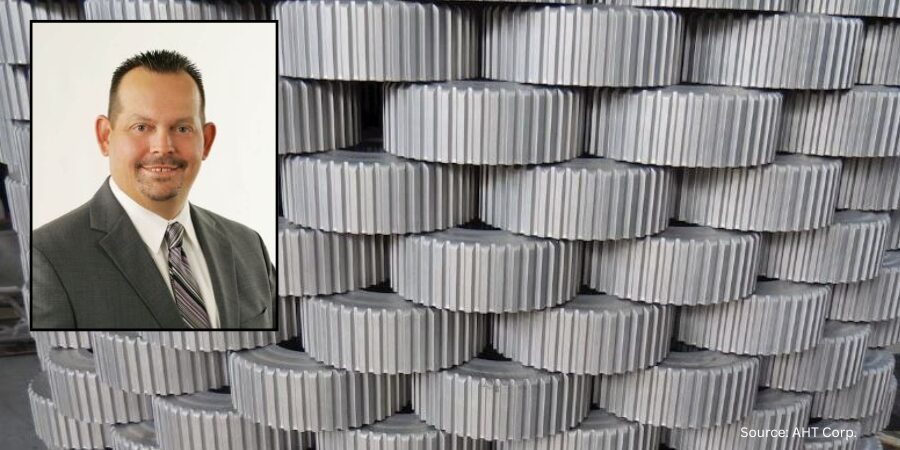

Reymak Makine Aş has integrated an eco-friendly Nitrex nitriding/nitrocarburizing system into its facility in Manisa, Türkiye. The heat treater offers a diverse product range, including an array of converting tools and CNC components, ranging from friction shafts/rings to reel cones, core chucks, and safety chucks. These components play a role in the packaging industry by ensuring alignment and tension of materials such as paper, film, foil, labels, textiles, and more. They prevent the occurrence of loose or soft rolls that could otherwise compromise product quality. Safety chucks, on the other hand, are specialized clamp devices designed for CNC and turning machinery, ensuring precision and accuracy in machining operations.

Recognizing the drawbacks of electroless nickel plating, Reymak sought to enhance the quality, efficiency, cost-effectiveness, and sustainability of its manufacturing operations. To achieve these objectives, the company selected a nitriding/nitrocarburizing system, specifically the compact model NXK-812, equipped with advanced process technologies. These technologies include Nitreg® controlled nitriding, Nitreg®-C controlled nitrocarburizing, and ONC® post-oxidation.

Utku Inan, Nitrex’s local representative in Türkiye, emphasized, “[This collaboration] demonstrates that by embracing sustainable innovations in its in-house heat treatment, Reymak is not only enhancing quality control but also streamlining logistics for faster lead times and cost savings – a genuine win-win scenario.”