Heat Treat Radio #18: Ben Gasbarre on Nitriding

Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Audio: Heat Treat Radio: Ben Gasbarre on Nitriding

In this conversation, Heat Treat Radio host, Doug Glenn, interviews Ben Gasbarre, president of Gasbarre Products Industrial Furnace Systems Division, about nitriding. Gasbarre Products is located in Plymouth, Michigan, where Ben oversees one of the recent acquisitions of Gasbarre products, the former JL Becker Co. Nitriding is one of the more popular thermal processes, so you’ll want to tune in to this podcast conversation with Ben Gasbarre of Gasbarre Products, one supplier of equipment for that process. Ben talks with Doug about the growth of nitriding in the heat treating market, particularly for domestic suppliers of equipment and services. This is especially true in the automotive manufacturing industry, but also in the aerospace and energy sectors.

Click the play button below to listen.

Transcript: Heat Treat Radio: Ben Gasbarre on Nitriding

The following transcript has been edited for your reading enjoyment.

In this episode of Heat Treat Radio, we’re going to talk about one of the more popular and growing thermal processes and one supplier of equipment for that process. The process: nitriding. And maybe a little bit of FNC (ferritic nitrocarburizing). The equipment supplier: Gasbarre Products.

Before we begin hearing from Ben Gasbarre, let me remind you that googling “nitriding” or “nitriding heat treatment” will bring up Heat Treat Today as the very first heat treat industry publication. Check out our site if you’re looking for nitriding or just good heat treating content. Every day our editorial team posts one new piece of heat treat content. Tuesdays are especially exciting. We call them ‘Technical Tuesdays’ because we post a new technical article every Tuesday. Pay a visit to our website, and don’t forget to support the advertisers and content providers you see on the site. Go to www.heattreattoday.com.

And one last thing—Do you know anyone under the age of 40 who is making a significant contribution to the heat treat industry? I’m betting you do, and it would be smart on your part to nominate that young professional to be a member of Heat Treat Today’s 40 Under 40 Class of 2019. From all of the applications received, our team chooses 40 outstanding, young heat treat professionals to be in our 40 Under 40 Class of 2019. You can see last year’s winners and nominate someone for this year’s award by going to www.heattreattoday.com/40under40. If you’re a supplier to the industry, think about nominating a young person from one of your customer’s organizations.

Today, we’re going to talk to Ben Gasbarre, president of Gasbarre Products Industrial Furnace Systems Division. Ben is located in Plymouth, Michigan, where he oversees one of the recent acquisitions of Gasbarre products, the former JL Becker Co. Although Gasbarre is phasing out some of the previous company names like JL Becker and Sinterite, they have, over time, become one of the major players in the North American heat treat market. Today, we’re going to talk to Ben about nitriding.

Today, we’re going to talk to Ben Gasbarre, president of Gasbarre Products Industrial Furnace Systems Division. Ben is located in Plymouth, Michigan, where he oversees one of the recent acquisitions of Gasbarre products, the former JL Becker Co. Although Gasbarre is phasing out some of the previous company names like JL Becker and Sinterite, they have, over time, become one of the major players in the North American heat treat market. Today, we’re going to talk to Ben about nitriding.

DG: Let’s talk about the nitriding market. What are you hearing and seeing?

BG: There is no doubt that nitriding has been around for a long time. It is not necessarily a brand new process, but it has certainly become a buzz word in the industry over the last number of years, and there are companies out there that have built their entire business on strictly doing different nitriding processes. We hear a lot of discussion and activity of more people wanting to get involved in it and in what aspects they can do that and where. There are a lot of process advantages to it. You get the wear and corrosion resistance, you get low distortion on the product which can lead to a lot of lower secondary processing costs for the ultimate end user. Then, on the heat treater side, there are advantages with the equipment in general. There is no oil quenching, so you’ve got environmental and plant cleanliness advantages there. There is limited part movement within the equipment, with some of the styles of equipment, so there are a lot of maintenance advantages. There are also the lower temps. With plant employees being around the equipment, operating temperatures in that 1,000 degree up range, it can be quite a bit more comfortable in the heat treat departments where this equipment is running. And then on the nitriding side, cycles are much longer, you can get higher equipment utilization, lower labor costs, and that type of thing. There are a lot of advantages for both the end user of the product and the heat treaters as well.

DG: Out in the marketplace, does it seem like the demand for this type of equipment or this type of process is up?

BG: Absolutely. We’ve done our own market analysis studies and have talked to people, and all of it shows strong growth and a lot of interest here in the US market. We’ve been successful over the years as well just with our current product line. It’s been a little more niche for us, but we’ve certainly had success with our product offering. What we’re looking for now, and what we believe is out there, is a broader need in the heat treating market. We feel the demand is there and really it is for a reliable domestic support for the equipment and the process. That’s where we see the need here domestically.

DG: So we’re getting a little more demand. Any sense of what’s driving that demand? Are we actually doing more nitriding, and if so, what markets might they be coming from, or what processes or materials?

BG: From our standpoint, being based right outside of Detroit, automotive is a big part of what we do and the people we talk to. There is a lot of activity on that side converting coatings and other processes from the coating over to the nitriding. We hear a lot of activity around that. It is heavy automotive, but we’ve also been taking interest and inquiries for aerospace and oil and gas applications as well. A big key to that though, again, for our end users is the flexibility—being able to run different styles, whether it be stainless steel parts or castings and things like that. The equipment has got to be able to handle both and keep it flexible for the user. You can also tie in atmosphere stress-relieving and tempering, not just nitriding, into these styles of equipment.

DG: What are you hearing about the equipment currently being offered in that space?

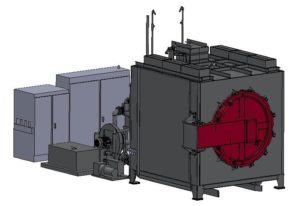

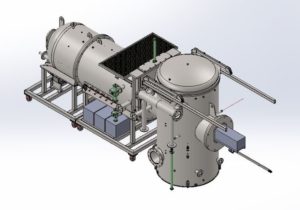

BG: We actually did a presentation at the FNA show this last fall that really focused on all of the different styles of equipment that you could use in this process. You have what I’ll call the classic integral quench furnaces, pit furnaces, and that kind of thing. On the integral quenches, they can be very flexible; you can process multiple loads; they are very forgiving for part cleanliness. But inherently with integral quench furnaces and the atmospheres and temperatures of the nitriding FNC [ferritic nitrocarburizing] process, you’ve got some safety challenges, and there is also a lot of maintenance that comes in with integral quench furnaces. Pit furnaces, on the other hand, are more single chamber, so your volume might be a little bit less, but you get a good quality part, you’ve got strong process control, but you do have infrastructure challenges with pit furnaces and loading mechanisms and maintenance for pits, so there are some challenges there. Where a lot of the interest has been is in the horizontal retort, in a lot of cases, with vacuum purge units associated with that. Those styles of equipment have been very popular in Europe and in other parts of the world, but are gaining a lot of traction here in the US. Again, they give very good part quality, strong process control, and your maintenance and infrastructure costs can be less. It doesn’t require a pit. There are not a lot of moving parts, so your focus is more on really ensuring your door seal and those kinds of things are good. Then you just continue to run the product and keep utilization high which is what everybody’s looking for.

DG: Let’s dig in a little deeper about what your company brings to the nitriding market.

BG: We have a lot of equipment out there that does this process, but what we’ve been developing is the horizontal retort, not gas nitriding, system that uses a vacuum purge system to allow for more effective quick purging and turnaround times in the furnace. It is something that is offered out there, but where we are unique is that we’ve built an extremely knowledgeable team for this product. This goes back to our roots to what my grandfather started the business over 45 years ago, having that knowledgeable staff that understands the customer’s processes, needs, and challenges.

We’ve brought people in that have sold this process, that have run the equipment, that have designed recipes, and that have troubleshot the process in the equipment. That’s where we are hanging our hat right now. We’ve got that staff, we know the equipment, and we are domestic, so we can offer that support that is reliable right here in the US and that is our approach right now. We do have areas that we are looking at and are working on. There are certain parts of the nitriding process that can challenge the end user, and we’re looking at things that can make equipment improvements and process improvements to ultimately solidify ourselves in that market for the long term.

DG: Besides your presence in the nitriding market, your company has had a pretty extensive history in the heat treat market generally, correct?

BG: Yes. Gasbarre was started in 1973 by my grandfather, George Gasbarre. He started doing powder compaction presses for the power metallurgy industry. My

grandfather started out as a parts maker and saw an opportunity in that market to design a press specific for powder compaction and he built the foundation on having a knowledgeable staff, design flexibility, maintenance friendly, and affordable, and these are principles that we continue to live by as we’ve grown the business. My father, Tom Gasbarre, and his brother, Bill, grew the business into what it is today. We’ve acquired 8 different companies, all based around powder metal presses or powder compaction presses, furnaces, and then tool and die. Today we’re made of up of a powder compaction solutions group which manufactures compaction presses and tool and die components for the particulate materials industries. We’ve got the thermal processing systems group that

manufactures a wide range of heat treating equipment. And we also have a manufacturing technologies group that just utilizes our broad resource of engineering and manufacturing capabilities to make equipment and components. We’ve been pretty successful in the glass industry, railroad industry, and mining industries. We’ve done some defense work as well. Just a couple months ago, we officially announced the transition to the third generation where my brother, Alex Gasbarre, is taking over as CEO. We’re proud of our past, and we are really excited about where we are today and the people and strategies we have in place to move us into the future.

DG: Let’s talk about the acquisitions you referenced just a moment ago. On the heat treating side of your business, tell us about the acquisitions.

BG: It’s kind of interesting with the re-branding we’re doing this year. We’re really pushing the Gasbarre name into the market, so that the Gasbarre name may be new, but we’ve been building equipment for 30 years. With the acquisition of Sinterite with their

continuous mesh belt furnace or powder metal sintering, that obviously complemented our compaction press line and got us into the thermal processing market. In 2003, we acquired C.I. Hayes, and that was really to meet our interests in getting to higher temperature applications with the pusher furnaces and vacuum furnaces, and they brought a long history and a large and solid base to us as well and got us into a bigger market outside of just powder metal. In 2011, we acquired J.L. Becker. That was really what built us out from a product line standpoint in the heat treating market. It complemented the other lines well in that we had a little bit of overlap, but with our focus out here, it’s more on the larger batch style equipment and some of the continuous processes associated with that. Therefore it really filled out our product line and gives us a broad variety of products to offer to the market.

DG: Where do you see Gasbarre having the strongest product offering?

BG: With the broad product line, we’ve got a few. The mesh belt product for sintering and brazing—we lead the industry in that. You won’t find a piece of equipment more suited for those applications, and we have an extremely knowledgeable staff for those. We have a hypercooler design for sinter hardening that has shown results that eliminate the need for additional heat treat, which I know can be a touchy subject with the readers here, but it is a pretty dynamic piece of equipment.

DG: But if it saves money for the end user, that is the key.

BG: Exactly. Also, our vacuum line is very unique in that we specialize in the multi-chamber systems. We can adapt to a wide variety of processes and different production demands. Work flows in and out of cells with our multi-chamber designs, and we can adapt to all of that. With our variety on the batch side, we can offer equipment that processes 500-pound loads all the way up to loads that are over 100,000 pounds. We can be competitive and technically competent in all of those areas.

DG: And your vacuum line?

BG: We offer both batch and continuous vacuum equipment, single chamber, and multi-chamber. Most of our designs, and where we are strong, is in the multi-chamber systems. We’ve developed a modular design that allows expandability and versatility for the end user. You can start with a single chamber and adapt in oil quenches or gas quenches. You can convert it from a batch system to a continuous system. The modular design gives people a lot of flexibility in what they can do. It also helps with maintenance, with how the systems are designed, so I think that has a lot of advantages for the end user that you don’t necessarily see in the market.

DG: And how about active markets, either markets you currently serve or markets where you see growth potential?

BG: Obviously with vacuum equipment, you get into aerospace quite a bit. The one that we’re excited about is the 3D printing. We’ve been working closely with a number of partners there. Binder jet companies are looking on the vacuum sintering side, and we’ve got expertise there. We have also gotten involved with some vacuum annealing for people doing direct metal laser sintering applications, and we’ve seen quite a bit of activity on that front. Obviously, it’s front and center in a lot of different ways, so we are looking to be very active in that market.

DG: If you’d like more Heat Treat Radio, it’s simple. Log onto the Google, then type in “Heat Treat Radio”. We’re the first thing that pops up. You can subscribe to Heat Treat Radio on iTunes or SoundCloud or you can find Heat Treat Radio on Heat Treat Today’s website which is www.heattreattoday.com. If you’d like to get in touch with Ben or learn more about Gasbarre products, you’re welcome to email me, Doug Glenn, at doug@heattreattoday.com, or you can email Ben Gasbarre directly at ben.gasbarre@gasbarre.com.

Don’t forget to nominate young professionals in the heat treat industry to be part of Heat Treat Today’s 40 Under 40 Class of 2019. Nominations are now open at www.heattreattoday.com/40under40.

Extra support for this episode of Heat Treat Radio was provided by the Industrial Heating Equipment Association (IHEA), where leaders in the heat treat industry meet to give back to the industry. Find out more about IHEA and especially about their fall educational seminars on September 24 and 25 in Cleveland, Ohio, by visiting www.ihea.org.

This episode of Heat Treat Radio is the sole property of Heat Treat Today and may not be reproduced without advanced written permission from Heat Treat Today.

This episode was produced and mixed by Jonathan Lloyd from Butler, Pennsylvania, who is still engaged and waiting to get married. I’m your host, Doug Glenn. Thanks for listening.

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.

Heat Treat Radio #18: Ben Gasbarre on Nitriding Read More »