Anodic Plasma Nitriding of Titanium Alloys

In this Technical Tuesday installment, Dr. Edward Rolinski and Dan Herring, respectively known as “Doctor Glow” and The Heat Treat Doctor®, explore how anodic plasma nitriding for titanium alloys avoids the damaging effects of conventional cathodic nitriding while improving wear resistance, corrosion resistance, and component reliability for aerospace and medical applications.

This informative piece was first released in Heat Treat Today’s November 2025 Annual Vacuum Heat Treating print edition.

To read the article in Spanish, click here.

Traditional plasma/ion nitriding is a well-established technology. However, it has issues that can be overcome by the newer anodic plasma nitriding method. This article introduces the idea of using anodic plasma nitriding for titanium and titanium alloys to avoid the damaging effect of conventional (cathodic) plasma nitriding. Read how this approach could provide harder, defect-free layers that improve wear, corrosion resistance, and overall component reliability for aerospace and medical critical parts.

What Is Anodic Nitriding?

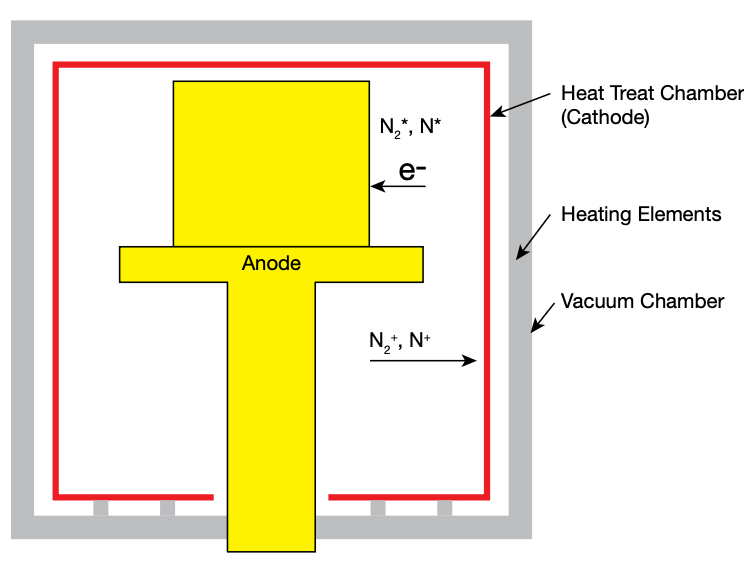

Anodic nitriding is a type of plasma nitriding process in which the component parts being treated are placed at an anodic (positive) potential instead of the usual cathodic (negative) potential. Unlike conventional plasma (cathodic glow discharge) nitriding, where the component is bombarded by high-energy positive ions, anodic nitriding involves low-energy electron bombardment of the component’s surface.

Anodic nitriding is particularly effective for materials with very high negative Standard Free Energy of nitride formation (e.g., titanium, zirconium) as it helps avoid or reduce the edge effect, a well-known problem in cathodic nitriding that leads to uneven ion bombardment and hardening on corners and edges.

Background: Plasma Nitriding Complexities

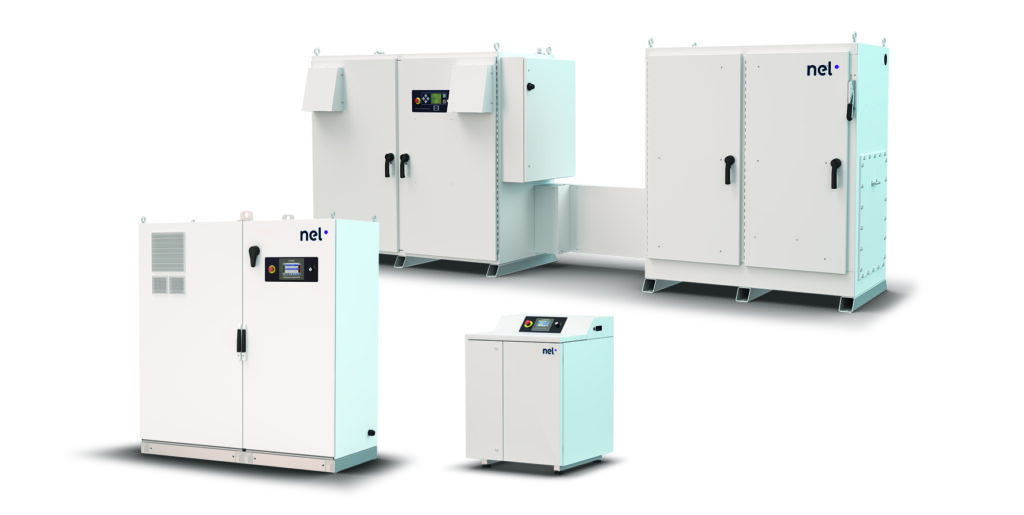

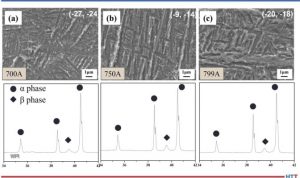

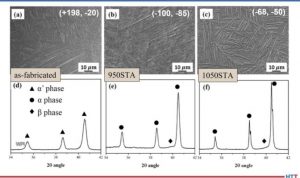

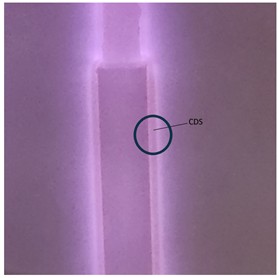

Glow-discharge plasma nitriding is applied to a wide range of materials, including cast irons, carbon steels, stainless steels, nickel, titanium alloys, and powder metal (Roliński 2014). The plasma nitriding and nitrocarburizing processes allow for the formation of surface layers known to have superior tribological properties (Roliński 2014). However, coverage of the parts with the glow discharge is not always uniform, especially when complex geometry loads are processed (see Figure 1).

Source: Roliński and Herring

Source: Roliński and Herring

Glow-discharge plasma nitriding is a thermochemical treatment involving high-energy particles. Ions of nitrogen or other gas species accelerate and gain energy in the cathodic dark space (CDS) around the workpiece — which is the cathode in a direct current electrode setup. They activate the surface first by sputtering to remove any native oxides present. The sputtering treatment also results in the generation of a substantial quantity of solid particles, generated from the part itself, including metal atoms that levitate near the surface of the part (Merlino and Goree 2004; Roliński 2005). In processing titanium, for example, this affects both adsorption and diffusion at the surface creating conditions that degrade layer quality (Hubbard, et al. 2010). A negative impact of this “dusty” plasma on the uniformity of the nitrided layer in complex-geometry workpieces has been reported (Ossowski, et al. 2016).

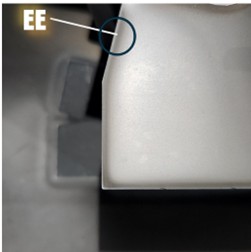

In addition, it is well known that there is a so-called corner/edge effect (EE) observed during plasma nitriding related to uneven circulation of these dust particles around the cathode (see Figure 2). In extreme situations, especially when complex geometry parts are treated, the EE caused by a non-uniform distribution of the electric field on corners, cavities, etc., results in excessive and non-uniform distribution of these plasma deposits (PD). In this way, the EE amplifies the already-present problem of redeposition, leading to the formation of various microdefects and uneven nitrided layer thickness (Merlino and Goree 2004; Roliński 2005, 2024; Ossowski, et al. 2016).

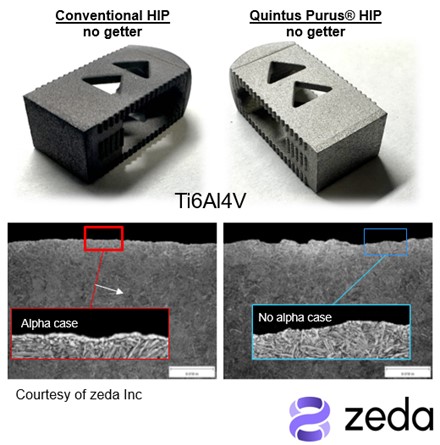

Plasma nitriding of titanium is usually performed at 680–1100°C (1256–2012°F). Negative aspects of using cathodic polarization on titanium include plasma/ion bombardment resulting in surface damage due primarily to micro arcing and contamination of the surface with the deposited compounds and their uneven distribution due to EE (Merlino and Goree 2004; Roliński 2005, 2014, 2024; Ossowski, et al. 2016). Although arcing has been eliminated by applying pulse plasma techniques, sputtering can only be controlled in a limited way, especially when complex geometry parts are nitrided. Therefore, gas nitriding in ammonia has been used occasionally for hardening titanium parts. A resulting golden appearance representing the presence of TiN nitride is produced on the surface (see Figure 3).

Anodic Nitriding of Titanium Alloys

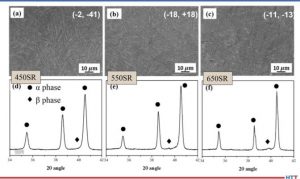

Research has been conducted on anodic plasma nitriding of steels (Zlatanovic 1986; Michalski 1993; Kenĕz 2018). Ammonia or active nitrogen species generated in the plasma can nitride the anode just as they do the cathode. The active species causing nitriding are active nitrogen atoms and highly reactive NH radicals (NH*) formed in near plasma. NH radicals (aka imidogen radicals) are chemical species with a nitrogen-hydrogen bond along with an unpaired electron. For titanium, hydrogen must be excluded in many situations because it reacts with titanium to form stable hydrides that embrittle the product (Roliński 2015).

The standard free enthalpy of formation of titanium nitrides has an exceptionally large negative value, which means that titanium nitride will form in a spontaneous way when the titanium anode reacts with excited nitrogen nearby (Roliński 2015). Switching the treated components from cathodic to anodic polarization offers several notable advantages. A glow discharge in pure nitrogen or argon generates only positive ions that are accelerated toward the cathode/workpiece. Because these gas mixtures lack negative ions, only electrons from the anodic glow strike the anode/workpiece. This results in activation of the surface without negative aspects of the collisions of the heavier particles, such as N2+ (i.e., a nitrogen molecular ion with a +1 charge), causing excessive sputtering. At the same time, charge-free particles of nitrogen, such as N2* and N*, react with the anode and are chemisorbed at the surface at sufficiently high temperature, leading eventually to formation of the diffusion layer.

It is believed that the anodic-nitriding process may have positive effects in treating precision parts made of titanium and other alloys for use in both the aerospace and medical industries. This method will allow treatment at the lowest possible temperature due to activation of the surface with the electrons from anodic polarization. The texture, appearance, and defect-free surface will produce a superior part and will enhance the performance of many of those components. This will be important when corrosion or optical properties of the surface play a significant role.

Anodic nitriding of titanium can be accomplished within a conventional plasma nitriding system, provided that the central anode is appropriately designed and positioned. This anode or portion of it must be made of titanium to prevent evaporation and transfer of any impurities to the parts.

Applications

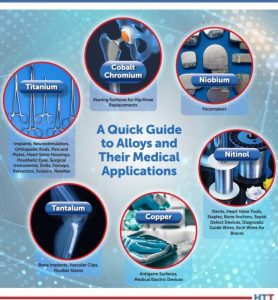

Titanium alloys are popular in orthopedics due to their bone-like elasticity, strength, and biocompatibility (Roliński 2015; Froes 2015). Surface engineering processes like anodic nitriding can play a significant role in extending the performance of orthopedic devices several times beyond their normal life expectancy.

Super elastic intermetallic materials, such as 60NiTi, are used in rolling element bearings due to their resistance to corrosion and shock (Pohrelyuk, et al. 2015; Corte, et al. 2015). They are typically prone to rolling contact fatigue (RCF) degradation. Any surface defects present in those components, such as local concentration of impurities or micro-cracks, will result in premature failure. Anodic plasma nitriding can be potentially used to harden the surfaces of bearing components made from these alloys by forming a hard, defect-free layer, which may improve their RCF properties.

It is expected that parts made of titanium or other alloys with the smooth surface subjected to the anodic nitriding will be microdefects-free, enabling their broad applications in medical field, aerospace industry, and optical and semiconductor devices.

References

Corte, Ch. Della, M. K. Stanford, and T. R. Jett. 2015. “Rolling Contact Fatigue of Superelastic Intermetallic Materials (SIM) for Use as Resilient Corrosion Resistant Bearings.” Tribology Letters 26: 1–10.

Froes, F. H., ed. 2015. Titanium: Physical Metallurgy, Processing and Applications. Materials Park, OH: ASM International.

Hubbard, P., J. G. Partridge, E. D. Doyle, D. G. McCulloch, M. B. Taylor, and S. J. Dowey. 2010. “Investigation of Mass Transfer within an Industrial Plasma Nitriding System I: The Role of Surface Deposits.” Surface and Coatings Technology 204: 1145–50.

Kenĕz, L., N. Kutasi, E. Filep, L. Jakab-Furkas, and L. Ferencz. 2018. “Anodic Plasma Nitriding in Hollow Cathode (HCAPN).” HTM Journal of Heat Treatment and Materials 73 (2): 96–105.

Merlino, R. L., and J. A. Goree. 2004. “Dusty Plasmas in the Laboratory, Industry, and Space.” Physics Today, July, 32–38.

Michalski, J. 1993. “Ion Nitriding of Armco Iron in Various Glow Discharge Regions.” Surface and Coatings Technology 59 (1–3): 321–24. https://doi.org/10.1016/0257-8972(93)90105-W.

Ossowski, Maciej, Tomasz Borowski, Michal Tarnowski, and Tadeusz Wierzon. 2016. “Cathodic Cage Plasma Nitriding of Ti6Al4V.” Materials Science (Medžiagotyra) 22 (1).

Pohrelyuk, I., V. Fedirko, O. Tkachuk, and R. Poskurnyak. 2015. “Corrosion Resistance of Ti-6Al-4V Alloy with Oxidized Nitride Coatings in Ringer’s Solution.” Inzynieria Powierzchni (Surface Engineering) 1: 38–46.

Roliński, E. 2014. “Plasma Assisted Nitriding and Nitrocarburizing of Steel and Other Ferrous Alloys.” In Thermochemical Surface Engineering of Steels, edited by E. J. Mittemeijer and M. A. J. Somers, 413–57. Woodhead Publishing Series in Metals and Surface Engineering 62. Cambridge, UK; Waltham, MA; and Kidlington, UK: Woodhead Publishing.

Roliński, E. 2015. “Nitriding of Titanium Alloys.” In ASM Handbook, Volume 4E: Heat Treating of Nonferrous Alloys, edited by G. E. Totten and D. S. McKenzie, 604–21. Materials Park, OH: ASM International.

Roliński, Edward. 2024. “Practical Aspects of Sputtering and Its Role in Industrial Plasma Nitriding.” In ASM Handbook Online, Volume 5: Surface Engineering. Materials Park, OH: ASM International. https://doi.org/10.31399/asm.hb.v5.a0007039.

Roliński, E., J. Arner, and G. Sharp. 2005. “Negative Effects of Reactive Sputtering in an Industrial Plasma Nitriding.” Journal of Materials Engineering and Performance 14 (3): 343–50.

Zlatanovic, M., A. Kunosic, and B. Tomčik. 1986. “New Development in Anode Plasma Nitriding.” In Proceedings of the International Conference on Ion Nitriding, Cleveland, OH, September 15–17, edited by T. Spalvins, 47–51. Cleveland, OH: NASA Lewis Research Center.

About The Authors:

“Doctor Glow”

Dr. Edward Rolinski, affectionately known as “Doctor Glow,” is a distinguished senior scientist having spearheaded research on plasma/ion nitriding since the 1970s. He holds advanced degrees in manufacturing technology and metallurgy, including a PhD and Doctor of Science. His focus has been on plasma nitriding processes, especially involving titanium alloys and powder metallurgy. Over his career, Dr. Rolinski authored numerous influential technical chapters and articles, including for ASTM International and the ASM Handbook, and is a prolific contributor to industry publications. After decades of leadership and innovation in surface engineering and heat treating, he is now a consultant in the heat-treating industry.

(The Heat Treat Doctor®)

The HERRING GROUP, Inc.

Dan Herring, who is most well known as The Heat Treat Doctor®, has been in the industry for over 50 years. He spent the first 25 years in heat treating prior to launching his consulting business, The HERRING GROUP, in 1995. His vast experience in the field includes materials science, engineering, metallurgy, equipment design, process and application specialist, and new product research. He is the author of six books and over 700 technical articles.

For more information: Contact Dan at dherring@heat-treat-doctor.com.

Anodic Plasma Nitriding of Titanium Alloys Read More »