Furnaces for Directionally Solidified and Single Crystal Castings

A leading aviation technology company will receive two new furnaces from a manufacturer of metal heat treatment solutions with North American locations. The furnaces will be used in the production of engine components, particularly directionally solidified and single crystal castings.

CEO

SECO/WARWICK Group

SECO/WARWICK will provide a Vector vacuum furnace and a VIM JetCaster furnace with a capacity of 25 kg, enabling the melting of nickel and cobalt alloys at temperatures up to 1700℃ (3092°F) to the Chinese aviation manufacturer.

“The device ensures a low percentage of casting defects, both macro and microstructural, as well as a significant reduction of the directional solidification casting process compared to the classical process due to increased mold withdrawal speeds,” said Sławomir Woźniak, CEO of SECO/WARWICK Group.

The latest jet engines use advanced blades cast produced by single crystal technology. The control system meets the needs of precise processes: casting, temperature control, as well as comprehensive data collection.

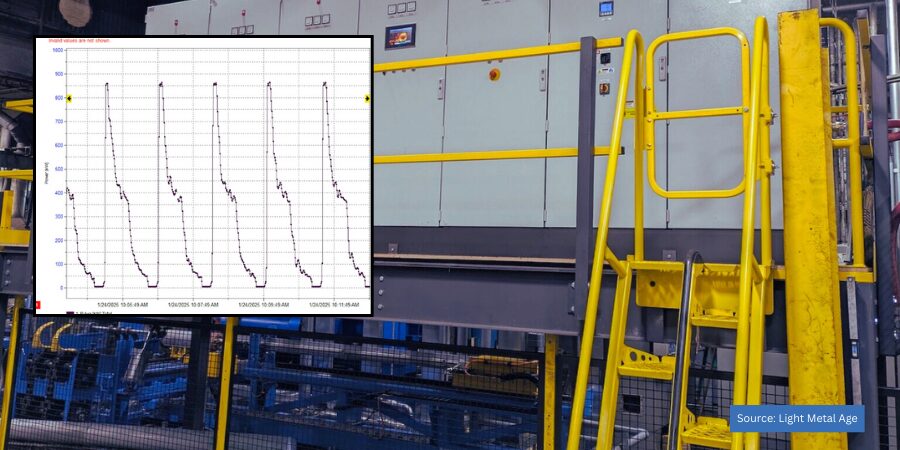

The Vector vacuum furnace is designed for aging and solution heat treatment processes. It achieves a maximum temperature of 1400℃ (2552°F) with a uniformity of ±5℃ (9°F) and can handle components with a total mass of up to 800 kg. Due to a high level of vacuum (up to 10⁻³ Pa), processes take place without intergranular oxidation, resulting in a quality surface for the components.

Press release is available in its original form here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Furnaces for Directionally Solidified and Single Crystal Castings Read More »