Robotic Laser Heat Treating Expands at Grand Rapids

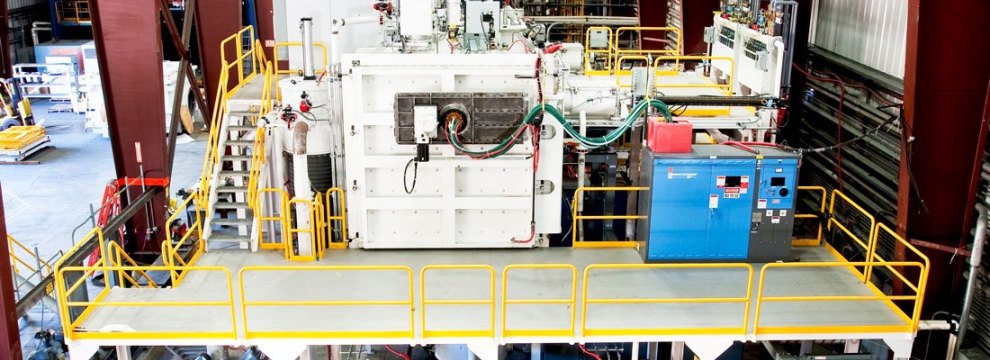

A commercial heat treater in Grand Rapids, MI is expanding its capabilities with robotic laser heat treating systems. This announcement was given with an open house invitation for the manufacturing community to witness this technology in action.

Laser Hard, Inc.'s technology is gaining momentum in automotive, mining, power generation, medical, aerospace and firearms industries, among others. Due to its low heat input and accuracy, companies request this process in place of other conventional methods that introduce a greater risk of cracking and distortion. The robot has built-in pyrometry for consistent heat at the work piece, reducing the risk of melting edges or overheating in an area that may have a thin cross section.

The open house will be on Thursday, October 13th, at 2766 3 Mile Road, Grand Rapids, MI 49534. There will be laser hardening demonstrations every hour from 2pm-6pm. Food and beverages from Pork Fat Slim's food truck will be available.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Robotic Laser Heat Treating Expands at Grand Rapids Read More »