OSLO – December 21, 2015 – Norsk Titanium AS announced today that the company has achieved Technology Readiness Level Eight (TRL 8) by concluding a test plan coordinated through the Federal Aviation Administration and launched in September, 2012. The results of Westmoreland Mechanical Testing & Research Inc.’s multi-year testing campaign demonstrate Norsk’s Rapid Plasma Deposition™ (RPD™) titanium parts meet demanding aerospace requirements and can now be supplied to the world’s premier aerospace & defense manufacturers for final certification and airframe integration.

“Working closely with Westmoreland, we have concisely documented how our innovative technology lives up to the highest standards of performance and integration under aerospace certification testing,” said Norsk Titanium President & Chief Executive Officer Warren M. Boley, Jr. “We subjected 1,300 structural titanium aircraft samples to an unrelenting barrage of static and fatigue tests and the results confirm what we already knew—Norsk Titanium’s RPD™ process is ready for the rigors of commercial aviation.”

“This was a very exciting program for us to conduct,” said Westmoreland Vice President of Operations Mike Rossi. “Norsk Titanium has done a great job of creating and maturing a new manufacturing technology and successfully navigating their RPD™ process through tensile, compression, pin bearing, shear and numerous fatigue tests at our facility.”

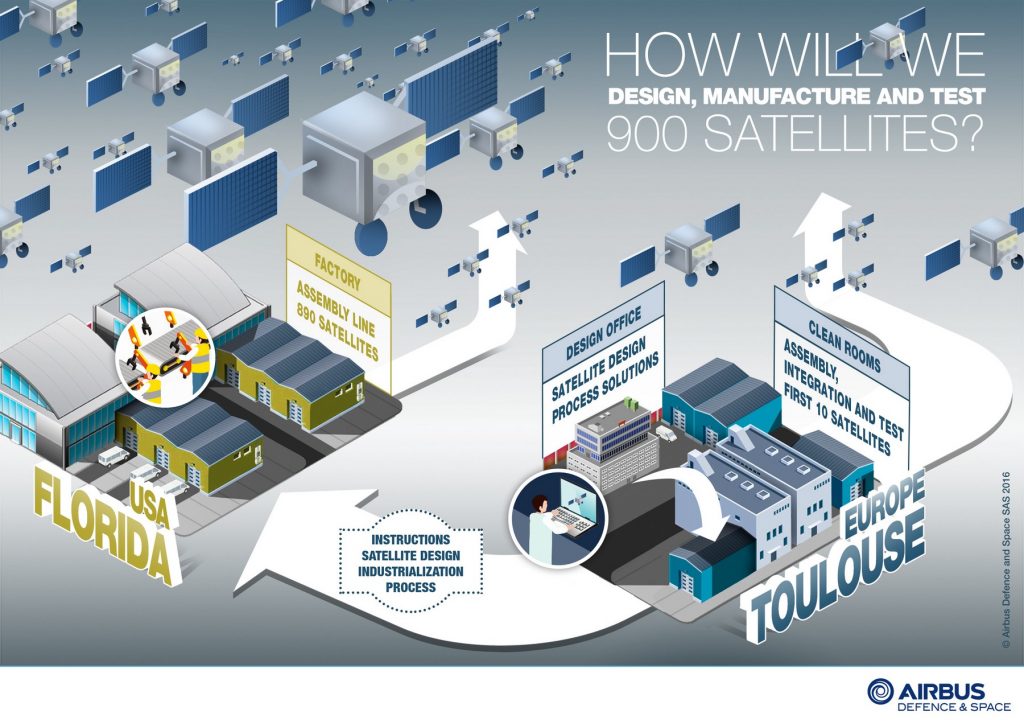

The achievement of TRL8 status provides Norsk Titanium with the ability to deliver precision structural parts for aerospace & defense applications as early as 2016. The company is orchestrating the establishment of a global supply base to satisfy aerospace demand through expanded operations and strategic alliances in Europe and the upcoming groundbreaking of the world’s first industrial-scale additive manufacturing facility in the United States.

The company has recently announced new appointments of seasoned aviation and defense executives, technologists, and production experts in support of new part qualification demand and to meet the escalating needs of its current aerospace customers. Delivery of commercial aviation qualification parts is underway, with the first approvals expected in early 2016, leading to the full commercial production of titanium aerospace components by the second half of 2

About Norsk Titanium AS

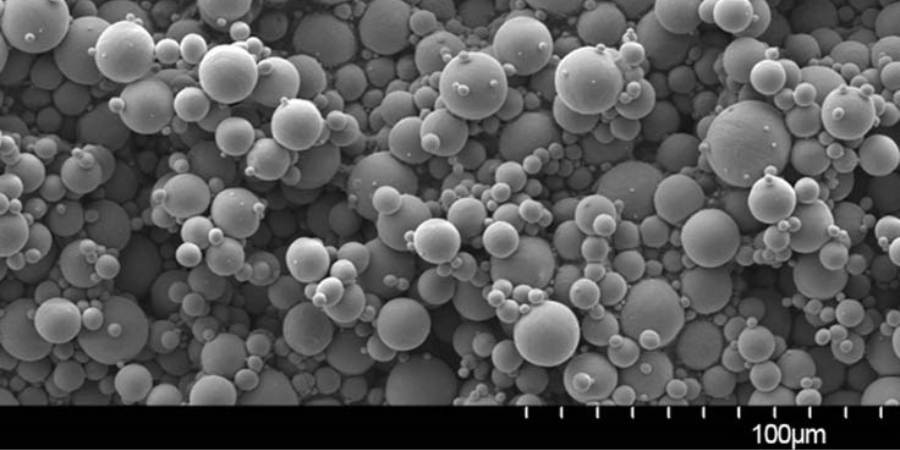

Norsk Titanium AS is the world’s pioneering supplier of aerospace-grade, additive manufactured, structural titanium components. The company is distinguished in the aviation industry by its patented Rapid Plasma Deposition™ (RPD™) process that transforms titanium wire into complex components suitable for structural and safety-critical applications. The Norsk research and development team is committed to displacing the age old and inefficient forging process with a precision wire deposition technology embodying substantial savings for aerospace, defense, and commercial applications. www.norsktitanium.com

![]() Source: Foundry Gate

Source: Foundry Gate