Auto Parts Manufacturer Adds EV/CAB Line

A continuous line for protective atmosphere brazing has been contracted by a company involved in the research, development, and production of precision metal parts for the automotive industry. The EV/CAB line is intended for the production of large-sized electric vehicle battery coolers.

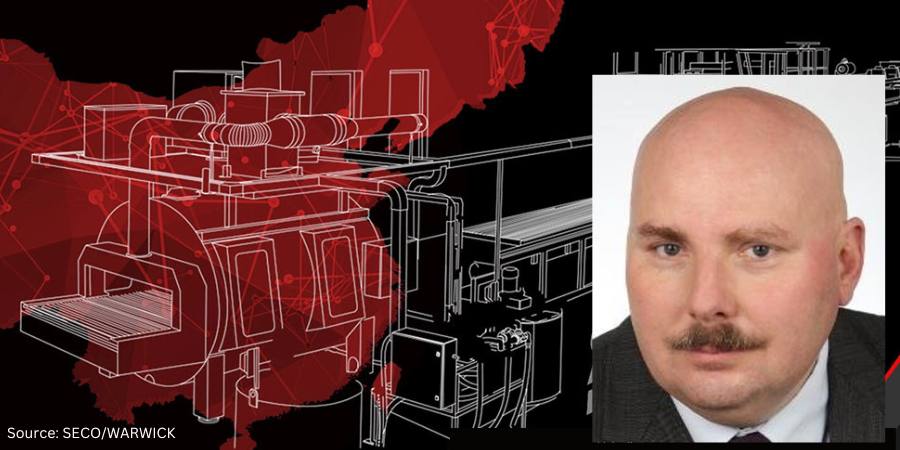

Vice President of Aluminum and CAB Products Segment

SECO/WARWICK

The EV/CAB line, manufactured and delivered by SECO/WARWICK, will help the company in their manufacture of automotive heat exchangers and is the first for the company, which has production plants in the US as well as Singapore, Malaysia, Thailand, Germany, and China.

“CAB continuous furnaces use a variable speed drive (to transport products) with a stainless-steel mesh conveyor belt. The controlled atmosphere brazing process heats the product to the brazing temperature, while maintaining a uniform product temperature in a protective nitrogen atmosphere devoid of oxygen,” said Piotr Skarbiński, vice president of the Aluminum Process and CAB Business Segment at SECO/WARWICK. “Societal awareness related to the need to care for the natural environment is growing globally, and consistent legal changes in this direction are causing the electromobility sector to grow.”

The CAB line ordered involves a hybrid gas-electric heating method and consists of a 1.6 m wide furnace TTBB chamber, radiation preheating chamber, radiation brazing furnace, cooling chamber with air jacket, final cooling chamber and control system. The furnace is fully electric; however, at the client’s request, space was provided for the installation of gas-powered heating, which provides the flexibility for future savings. Radiation CAB furnaces provide continuous brazing of products with similar dimensions and features. The temperature is distributed evenly over the entire length of the belt due to several independent heating zones.

In addition to manufacturing electric vehicle battery coolers, the company produces precision metal parts for the computer and telecommunications industries.

Press release is available in its original from here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Auto Parts Manufacturer Adds EV/CAB Line Read More »