We’re celebrating getting to the “fringe” of the weekend with a Heat Treat Fringe Friday covering news about a metals company enhancing its processing line with an atomizer, increasing its capability to produce metal powders for the advanced manufacturing industries that it serves. Atomization, a process that forces molten metal into a controlled environment through a nozzle at high pressure, improves sustainability and efficiency in metals production for industries such as aerospace, medical and defense.

While not exactly heat treat, “Fringe Friday” deals with interesting developments in one of our key markets: aerospace, automotive, medical, energy, or general manufacturing.

A multinational metals company recently bolstered its processing line by adding an atomizer for the production of metal powders. The atomizer will be installed at one of the company’s U.S. production facilities and is capable of producing a wide variety of metal powders, optimized for both throughput and maintenance.

Retech, a division of SECO/WARWICK Group and a pioneer in advanced metallurgical equipment, has announced the procurement and the delivery and installation of the advanced manufacturing equipment to the metals manufacturer.

Managing Director

Retech

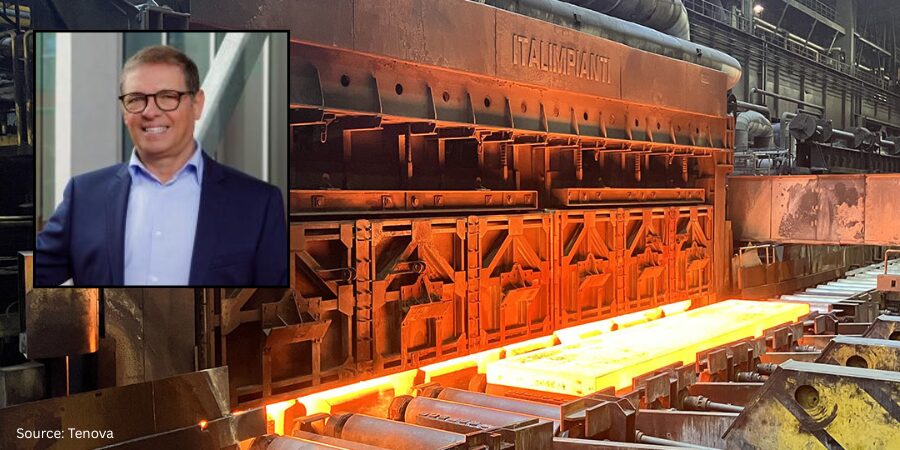

“We stuck with them,” said Earl Good, president and managing director at Retech. “We maintained the response times they needed, going above and beyond. This level of dedication was crucial in meeting their ambitious timeline, from RFQ to turnkey execution.”

The atomizer system is designed to be highly efficient, reducing operational costs and environmental impact. The system’s all-electric process ensures zero carbon emissions, aligning with sustainable production practices, and the inert gas recovery and recycling enhances resource efficiency and reduces waste. Maintenance features allow for rapid changeover between heats, minimizing downtime.

The press release is available in its original form here.