What Have You Learned from the Combustion Corner? Part 2

![]() Since February 2021, Heat Treat Today has had the privilege of publishing the Combustion Corner. In each of these columns, John Clarke, technical director at Helios Electric Corporation, shares his expertise on all things combustion. In this Technical Tuesday, we're taking a moment to review more of the key points from John's columns. As always, we hope this review helps you to be more well informed, and to make better decisions and be happier. Enjoy these five summaries of the second half of the Combustion Corner columns. To view each installment, click the blue heading below.

Since February 2021, Heat Treat Today has had the privilege of publishing the Combustion Corner. In each of these columns, John Clarke, technical director at Helios Electric Corporation, shares his expertise on all things combustion. In this Technical Tuesday, we're taking a moment to review more of the key points from John's columns. As always, we hope this review helps you to be more well informed, and to make better decisions and be happier. Enjoy these five summaries of the second half of the Combustion Corner columns. To view each installment, click the blue heading below.

How To Lower the Cost of Operating Your Burner System

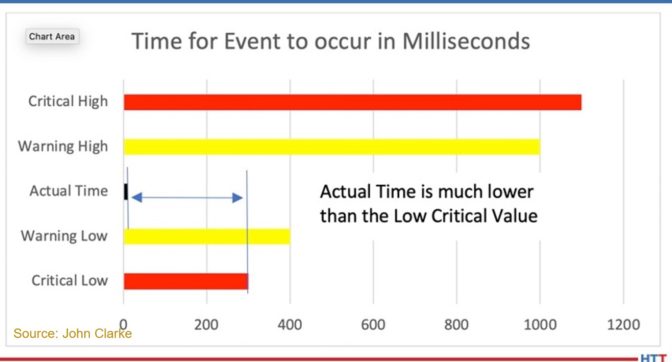

Process consistency and energy savings are inextricably linked. To lower operating costs and increase process consistency, John Clarke suggests asking three questions: What temperature is my furnace or oven, really? Do I have excessive safety factors built into my process to compensate for not knowing the temperature at the core of the part being heat treated? How much fuel can I save with a shorter cycle?

Process consistency and energy savings are inextricably linked. To lower operating costs and increase process consistency, John Clarke suggests asking three questions: What temperature is my furnace or oven, really? Do I have excessive safety factors built into my process to compensate for not knowing the temperature at the core of the part being heat treated? How much fuel can I save with a shorter cycle?

Are You Holding on to Uncashed Checks?

Reducing natural gas consumption is not the only way heat treaters can save money. Verifying internal furnace pressure, rebuilding door jams, and taking the time to consider if excess air is reducing combustion efficiency are all as good as cashing a check. Maintaining a consistently uniform furnace temperature saves more money than the energy conserved from using less fuel.

"To not invest money on worthwhile projects makes as much sense as not depositing your paycheck."

The "Known – Unknown": Preparing Your Facility for Unpredictable World Events

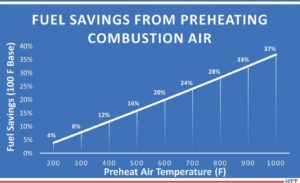

The biggest question mark in a heat treater’s mind is often, “What will natural gas prices be in the future?” Since we cannot know the answer to that question, what are some things heat treaters can do to prepare for unpredictable natural gas prices? Burner recuperation, using the waste heating exiting the furnace to preheat combustion air, is a tried-and-true method for reducing consumption. Before trying burner recuperation, the following questions need to be asked: How much will it cost? How much can be saved? Can the existing furnace accept the higher flame temperatures?

Natural Gas Revisited

In this installment of the Combustion Corner, John Clarke takes some time to reassure the heat treating industry of two key facts about the United States' natural gas market:

In this installment of the Combustion Corner, John Clarke takes some time to reassure the heat treating industry of two key facts about the United States' natural gas market:

- 40% of the electricity in the U.S. is generated using natural gas.

- U.S production of natural gas was at al all-time high in 2021 and is rising. The U.S. is the largest producer of natural gas in the world.

With these two facts in mind, John postulates that the U.S. can be sure of a reliable supply of natural gas in the future, but, given the price differential between European and U.S. markets, American heat treaters are likely to see an increase in price per mmBTU.

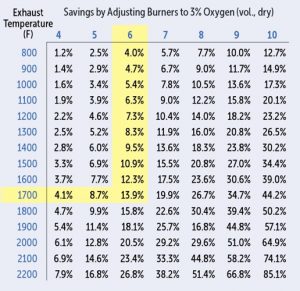

How To Make $17,792.00 in a Couple of Hours

Saving money is the same as making money. Adjusting the oxygen levels of flue products measured with a handheld combustion analyzer to operate at an optimal percentage may yield more savings than you think. Reducing a non-recuperated burner from 6% oxygen to 3% oxygen garners $17,792 extra a year for the heat treater. A quick solution with a hefty payback rate.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

What Have You Learned from the Combustion Corner? Part 2 Read More »