For the next series of articles on heat treaters and combustion, the focus will be on the cost of natural gas and how we can reduce its consumption. Given significant movements in natural gas prices, it is essential we shift our focus to this important pocketbook issue.

For the next series of articles on heat treaters and combustion, the focus will be on the cost of natural gas and how we can reduce its consumption. Given significant movements in natural gas prices, it is essential we shift our focus to this important pocketbook issue.

This Technical Tuesday column appeared in Heat Treat Today’s November 2021 Vacuum Furnace print edition. John Clarke is the technical director at Helios Electric Corporation and is writing about combustion related topics throughout 2021 for Heat Treat Today.

Technical Director

Helios Electrical Corporation

Source: Helios Electrical Corporation

What Is the Cost To Operate My Burner System?

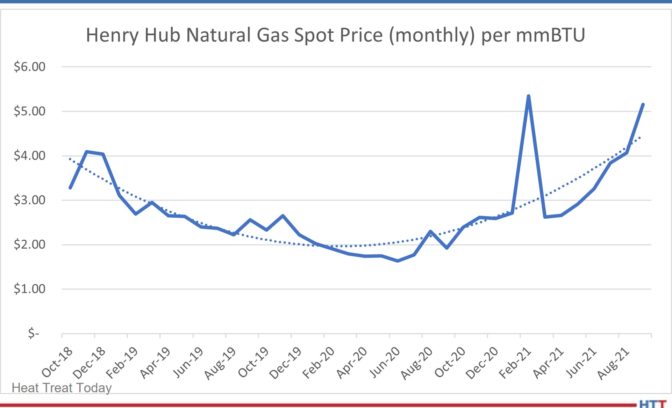

We will begin this and future articles by looking at natural gas prices and price forecast(s) that are published by the Department of Energy’s Energy Information Agency (EIA). Unlike the price for gasoline, we don’t drive past large, illuminated billboards displaying the current price of natural gas on our way to work, even though it is a significant operating cost for all heat treaters. Even if you operate primarily electrically heated equipment, natural gas is likely used to generate your electrical power. Obviously, neither Heat Treat Today or this author make any claims as to the accuracy of these projections. In other words, please don’t shoot the messenger. The American taxpayer funds this agency and it is only reasonable that we see what they have to say.

Let’s start with a quick definition. Henry Hub is a gas pipeline located in Erath, Louisiana that serves as the official delivery location for futures contracts on the New York Mercantile Exchange. This hub connects to four intrastate and nine interstate pipelines. It is unlikely any industrial consumer pays the Henry Hub price alone for the natural gas they consume. There are a great many other factors that determine the price that appears on your monthly bill; but the Henry Hub price is indicative of pricing trends and represents a consistent way to discuss the cost.

A good website to bookmark in your browser is www.eia.gov/naturalgas/weekly/. It is a quick read and will be the primary reference for my monthly sidebar. Let’s first look at the spot price trend. The spot price is the current price at which a natural gas can be bought or sold for immediate delivery at the Henry Hub. There is volatility in the price of natural gas because of supply, demand, and trading activities (speculation), but when we expand the time horizon, it provides a representative look at the pricing trend. This trend will be reflected in the price we will pay in the future. The prices quoted are in terms of U.S. Dollars per 1,000,000 BTU — roughly 1,000 SCF of natural gas.

The EIA also provides forward-looking projections — but we will leave it to the reader to explore this information on the EIA website. The intent of this series of articles is not to provide the basis of trading futures, but rather to provide some ideas on how to save money.

We can see a definite upward trend. When we combine this data with our understanding that natural gas is increasingly being used to displace coal to generate electricity and North America’s increasing capacity to export liquified natural gas (LNG), there is reason to believe this is a durable trend. We can expect to pay more next year than the recent past to heat our equipment. And in time, this higher fuel cost will lead to higher electrical rates.

How Can I Save Natural Gas?

To save natural gas, we can optimize our processes, reduce unnecessary air, and contain heat within the furnace and/or capture the energy that leaves our system to preheat work or combustion air. Ideally, we should take advantage of all these opportunities — provided the effort pays for itself. In general, operators of heat processing equipment are aware of these opportunities but are not always confident when determining the payback for their investments in time and capital. We will endeavor to bring clarity to these decisions by not only discussing opportunities, but also discussing how to quantify the value of the opportunities. The following are the questions that will be answered in future articles:

To save natural gas, we can optimize our processes, reduce unnecessary air, and contain heat within the furnace and/or capture the energy that leaves our system to preheat work or combustion air. Ideally, we should take advantage of all these opportunities — provided the effort pays for itself. In general, operators of heat processing equipment are aware of these opportunities but are not always confident when determining the payback for their investments in time and capital. We will endeavor to bring clarity to these decisions by not only discussing opportunities, but also discussing how to quantify the value of the opportunities. The following are the questions that will be answered in future articles:

Optimizing the Process:

- How do I know when the material I am heating is at the desired temperature?

- Do I have excessive factors of safety built into my process to compensate for not knowing the temperature at the core of the part being heated?

- How much fuel can I save with a shorter cycle?

Reducing Air or Containing Heat:

- Is my furnace or oven at the correct internal pressure?

- Is it time to rebuild door jams?

- How much fuel is wasted because I am not containing heat within the furnace or letting excessive air reduce my combustion efficiency?

Reducing the Heat Exiting the System:

- Can I justify installing recuperators to preheat combustion air?

- Can the heat from my system be used to preheat work? If so, will I shorten my cycle time and save fuel?

No one likes rising energy prices, but if the trend is up, it is better to recognize reality and invest accordingly. It is our wish that future columns will provide ideas and tools to help you get the most from the energy you consume. If you have specific requests or questions that might guide our discussions, please let us know.

About the Author:

John Clarke, with over 30 years in the heat processing area, is currently the technical director of Helios Corporation. John’s work includes system efficiency analysis, burner design as well as burner management systems. John was a former president of the Industrial Heating Equipment Association and vice president at Maxon Corporation.