Hydrogen is essential for many heat treating processes, but what happens when your supply runs out?

In today’s episode of Heat Treat Radio, Devon Landry of Nel Hydrogen joins Heat Treat Radio Host Doug Glenn to discuss the potential risks of delivered gas and how on-site generation can secure reliable, high-purity hydrogen. This episode highlights the advantages of on-site generation and what questions to ask before making the switch.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

The following transcript has been edited for your reading enjoyment.

Hydrogen Usage in Thermal Processing (4:05)

Doug Glenn: All right, let’s talk hydrogen. I think the first thing I’d like to do is talk about the basics, how hydrogen is used and what it’s used for in thermal processing.

Can you give us a 30,000-foot view on hydrogen and why are we using it in thermal processes?

Devon Landry: Hydrogen is widely used in heat treat and processing. It’s a powerful reducing agent for surface cleaning and sintering success.

Photo Credit: Nel Hydrogen

It has the highest heat conductivity of any gas, so we can enter and exit parts quicker. It has lower density relative to air and nitrogen, which makes it really straightforward to manage. It burns off easily, readily, cleanly. The only true byproduct of that would be water.

Doug Glenn: We are talking about the security of hydrogen supply.

How important is it for people who need hydrogen to have it, and what happens if they don’t have it — what are the risks here?

Devon Landry: My predecessor, Dave Wolff, used to say it’s like yeast for a pizzeria. It’s a very small part of the cost, but if you don’t have yeast, you don’t have pizza. If you don’t have pizza, you don’t have business. So if you don’t have hydrogen, you can’t really run your processes.

The same with running out of hydrogen. If you’re halfway through a batch and you run out of hydrogen, that whole batch is done. If that batch isn’t finished and you don’t have any hydrogen left, you don’t have business. You have to send employees home and stop your production. You can run into a lot of problems.

Doug Glenn: If you’re processing high-value parts, it’s not just a matter of simply running out of parts and not being able to finish the load. That load could be worth a quarter of a million dollars.

Devon Landry: That’s correct, the parts are completely done; you won’t be able to use those parts — it’s a completely wasted batch. So, you would lose money, not just from excess production, but that batch as well.

On-Site Hydrogen Generation vs. Supplied (06:25)

Doug Glenn: There’s different ways of getting your hydrogen, it can be supplied or Nel, the company you’re with, supplies the equipment to manufacture hydrogen on-site. What type of risks are companies exposing themselves to if they are not generating their own hydrogen?

Devon Landry: Delivered hydrogen is really the only other way to get your hydrogen, and that’s through industrial gas suppliers. I see a shortfall in the future, especially with liquid hydrogen production. There are many hydrogen plants that are getting canceled or delayed.

You see, it costs a lot of money to make these plants, and if the financial advisors deem that the plant is not going to make money, they’re not going to do it.

For the Artemis rocket, that takes a full day’s production of liquid hydrogen in the U.S. to fill up. And there are many projects out there that are requiring liquid hydrogen, which is why I see a shortfall coming.

If you can’t get the hydrogen from your industrial gas supplier, where are you going to get it?

That’s where Nel Hydrogen comes in. With generating on-site, you take control of your hydrogen supply.

Doug Glenn: You mentioned that you foresee a lack of supply and that some of these hydrogen plants aren’t being approved.

Why aren’t these plants being approved to be built?

Devon Landry: They cost a lot of money to build and industrial gas companies have a long-term strategic focus, with capital discipline kind of upfront. If you’re going to build a plant and shareholders are not going to see any returns on it, then they’re not going to do it.

So we’ve seen a lot of cancellations. They haven’t really have a good commitment to shareholder value, and they emphasize on strong fundamentals there.

Doug Glenn: At one point in time, there was a lot of talk about hydrogen fuel cells. And everybody wanted to do hydrogen. I haven’t heard much about that recently. Do you think that might have something to do with the cooling off of the hydrogen market?

Devon Landry: Yes, I think so. There was a hydrogen world out there, and people really wanted to build new plants, have fueling stations. There’s so much you can do with hydrogen. But policies around hydrogen are affected by different administrations. With the current administration, they’re taking some of those incentives away. So there’s not as much money being provided as an incentive.

Doug Glenn: This is all the more reason to be very careful about your hydrogen supply. Not only your current hydrogen supply, but in the future. With politics and different administrations, sometimes hydrogen fuel cells is on, then it’s off. As a result, supplies may be a bit dicey. Therefore, it’s probably well worth people paying close attention to where they’re getting their hydrogen now and what the future looks like.

Your input is really important here.

Proton Exchange Membrane (10:23)

Photo Credit: Nel Hydrogen

Doug Glenn: Tell me about PEM; what does that stand for?

Devon Landry: PEM stands for proton exchange membrane. It’s a differential pressure system, where hydrogen is allowed to pass through the membrane but oxygen cannot.

We’re taking ultra pure water with a resistivity of greater than one mega ohm. That’s going through into the cell stack and the electrolysis takes place there. The hydrogen is allowed to pass through that membrane; the oxygen is not. So, the hydrogen goes towards the process.

Doug Glenn: Oxygen and/or water is the only byproduct.

Devon Landry: Yes, and it returns to the main reservoir, and that oxygen gets vented, either out of vent stack or into the room.

Doug Glenn: The primary markets that Nel Hydrogen serves are mostly industrial, and Nel can also do much larger units. Can you tell me about that?

Devon Landry: With alkaline and PEM both, we can do megawatt style units. I handle primarily the industrial units, and we can go all the way up to 100, 200, 300 megawatt systems — a very vast range.

Doug Glenn: Most businesses in our industry would not need that much, but it’s good for our people to know that you guys have expertise, not just in the sizes that are good for them, but larger sizes as well.

Source: Nel Hydrogen

PEM Process vs. Alkaline (12:05)

Doug Glenn: We have discussed the PEM process. Can you explain the difference between how the hydrogen is extracted from the PEM process vs. alkaline?

Devon Landry: The alkaline system uses KOH, which is highly corrosive and dangerous to handle. You have to fill it up, so there’s a safety aspect with that. In addition, the purity that you’re getting out of the alkaline process is not quite as high as PEM. I think it’s 90%, but it can be 97 to 98%.

With the PEM process, the only output you’re getting is hydrogen and some water, and we mitigate that water with a dryer inside the system. We get five nines purity plus: 99.999% purity plus.

You really need that purity in a lot of the heat treating processes to give you the coloration of the pieces that you’re putting through. With the industrial gas suppliers, you often have to pay a premium to have higher purity. Many times, when you send those cylinders or a tube trailer back to get it refilled, they do not test it to find out exactly what the purity is unless you specifically request that. So your purity might differ every now and then, which means you’re not going to get the exact effect on your process that you would like.

The way the industrial suppliers are making that hydrogen is through steam methane reforming. It’s very energy-intensive, and carbon is a major by-product of that process.

Our machines are as carbon free as your electricity supply line: if you’re feeding it with solar and wind energy sources, utilizing renewable energy, then you are at a zero carbon footprint.

Doug Glenn: You would have true green hydrogen. If your electricity supplier was green, then you would be really producing green hydrogen, which would be very good.

Delivered Gas vs. Hydrogen Generation (14:55)

Doug Glenn: What questions should companies be asking if they are considering moving away from bulk or delivered gas to on-site hydrogen generation?

Devon Landry: To have a hydrogen generator on-site, you need to know your flow and your pressure. There are going to be operational and capital costs.

The capital costs are a little larger with the hydrogen generator. So you’ll need to know how much gas you’re using and what pressure you’re using at. We have calculators to determine which unit would be best for you based on those questions.

If the capital costs are a little too high, which they are for some companies, then we do have leasing options that will help with that capital cost. We can break it down monthly, even for a 10-year period of what you would be spending for your delivered gas versus a hydrogen generator on-site.

Doug Glenn: So, you can do that analysis for businesses if they can provide their current expenditures for delivered hydrogen and usage, and then you can do a comparison to advise them on what it would cost if they were to transition to on-site generation?

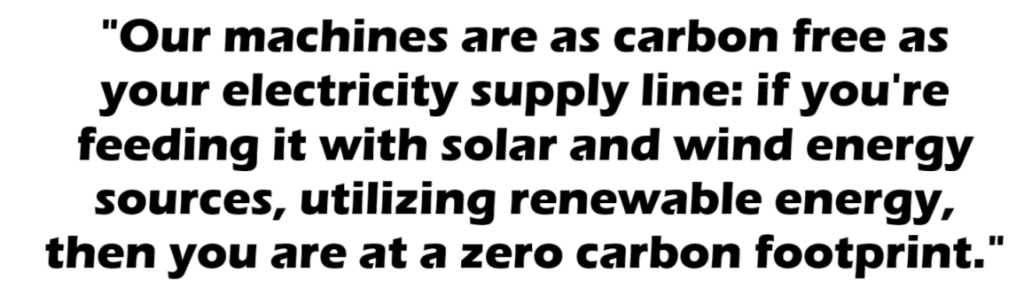

Devon Landry: Yes, exactly. Industrial gas suppliers can come with a lot of bills, so you have to pay attention. There could be a trailer rental fees, cylinder rental fees, delivery fees — a lot of bills combining into one. They also generally require signing a contract with them that could be seven plus years, and you have to provide quite a long notice to be relieved of those contract obligations as well.

Doug Glenn: The capital cost could potentially be different, meaning probably more for an on-site generator for hydrogen. When you think of bulk gases, the operating costs are quite low for delivered gas.

How about operational costs for hydrogen?

Devon Landry: The cost of hydrogen generation is going to be the cost of your electricity. The price per kilowatt is going to tell you how much cost per standard cubic foot that you’re going to be paying for it.

Doug Glenn: Electricity is really the only major cost operationally. How about maintenance costs?

Devon Landry: The maintenance cost depends on which machine you select. We build maintenance costs right into the calculator that tells you how much the costs will be per year. There’s a quarterly maintenance cost, which is just basically a calibration, and then a yearly maintenance kit that you can put in yourself.

Doug Glenn: Do you need to have any special personnel to run it or is it self-maintaining?

Devon Landry: It pretty much takes care of itself. If there’s a problem with it, a pop up will let you know the problem, and you can go to the manual to learn exactly what the problem is. If you have a regular maintenance crew on site, many power plants have these, then you usually have somebody that can do it.

It’s generally filter changes and updates like that.

Community Perception on Hydrogen Generation (18:25)

Doug Glenn: Pertaining to public perception, how has the community responded to hydrogen generation?

Devon Landry: Most people like it better. We like to refer to it as the good neighbor benefit. Would you rather look outside and see a gigantic tank full of combustible gas or a quarter inch, stainless steel line?

Fire marshals love it because we store less than seven standard cubic feet on our biggest machine, internally.

And then when we hit the stop button, or if the generator shuts down, the hydrogen is all vented out into the atmosphere. There’s no stored hydrogen — only a minimal amount inside the machine.

Doug Glenn: No rocket ships in your backyard.

Devon Landry: Looking out the window, I’d rather see the sky and some bushes rather than a big tank.

Is Hydrogen Generation Right for Your Company? (19:30)

Doug Glenn: Are there instances where generating hydrogen on-site doesn’t make sense for a company or when bulk delivery is a better deal?

Devon Landry: This is why we have those calculators. I don’t need a company buying a generator if it’s not going to save them money or if it’s not going to be easier for you. It’s really only practical when you’re under 10,000 standard cubic feet per hour.

Doug Glenn: Is that amount for a very large industrial manufacturing plant?

Devon Landry: Yes, that’s quite a bit.

Doug Glenn: Is there any amount that’s too small in which it wouldn’t make sense to have a generator?

Devon Landry: No, our smaller generators put out about 10 standard cubic feet per hour, about 4.9 liters per minute, and it’s on-demand. If you need the smallest amount possible, they’ll put that out for you. If you don’t need any further for the interim, it will basically sit there in idle. These generators are fully on-demand and give you exactly what you need.

Doug Glenn: Which companies currently are out there that it really makes sense for them to look at on-site hydrogen generation?

Devon Landry: Really, anybody that needs hydrogen. If you’re not excited about your delivered hydrogen, if you’re having issues with it, if the cost is too high, we have a lot of different industries that we run with. Many are heat treating and metal processing business. There’s also chromatography, gas chromatography, MOCVD, many different industries. If you have delivered hydrogen, generating hydrogen on-site would be worth looking into.

Final Thoughts (22:45)

Doug Glenn: Where is the corporate headquarters or the world headquarters for Nel Hydrogen?

Devon Landry: Nel Hydrogen is headquartered in Oslo, Norway.

Doug Glenn: How long has company existed?

Devon Landry: It started in 1927.

Doug Glenn: Where’s the main headquarters in the U.S. or North America?

Devon Landry: We’re in, Wallingford, Connecticut, and all of our PEM machines are built there.

Doug Glenn: Very good. I’d like to thank all the everyone for listening.

Hopefully you found this episode enjoyable and informative. Thanks again, Devon. Appreciate you being here.

About the Guest

Senior Field Engineer and Technical Lead

Nel Hydrogen

Devon Landry has been an integral part of Nel for 16 years, establishing himself as a leading expert in industrial on-site hydrogen generators. With over 15 years as a Senior Field Engineer and Technical Lead in Technical Service and Customer Support, he has played a key role in delivering top-tier service and expertise to Nel’s global customer base. His extensive experience includes traveling more than 3 million miles worldwide, working across diverse industries and customer sites.

Beyond his technical proficiency, Devon brings strong leadership and business acumen. As an entrepreneur, he successfully founded and managed a craft brewery and taproom in Connecticut for six years, leading a team of seven employees. This experience further enhanced his ability to blend technical expertise with strategic management and operations.

For more information: Contact Devon at dlandry@nelhydrogen.com