Renewable fuels or hydrogen have entered the scene as these are fuels that contain little or no carbon. So, no carbon in the fuel means no CO2! These fuels present an excellent opportunity to significantly reduce carbon.

This Sustainability Insight article was composed by Brian Kelly, manager of Application Engineering at Honeywell Smart Energy and Thermal Solutions (SETS) and president of the Industrial Heating Equipment Association. It can be found in Heat Treat Today's August 2023 Automotive Heat Treating print edition.

The need to understand the impact of greenhouse gases (GHGs), especially carbon-based emissions, on climate change is gaining much more interest recently from organizations that have industrial heating processes. Most industrial heating processes are fueled by carbon-based fossil fuels such as natural gas, propane, fuel oil, diesel, or coal. In basic terms, if you have combustion processes in your organization, you are emitting carbon (CO2). Impacts on climate change due to these carbon emissions have prompted government and corporate actions to reduce carbon. These actions are creating unique new opportunities for more sustainable and lower carbon process heating methods. In this article, we will focus on ways to reduce carbon in typical fossil fuel fired heat treat thermal processes. First step: Figure out where you are today. Do you know?

Assess Your Carbon Footprint

Image Source: Honeywell

More and more companies are interested in understanding their GHG/carbon footprints, so they can determine what processes are their biggest CO2 offenders, and on what assets to focus on in order to have the largest impact on reducing carbon. Whether your thermal processes are being heated by fossil fuels (typically natural gas) or electrically, each will have a carbon footprint. Fuel gases are being burned to provide the heat and they produce CO2 as a result. Most electrical power is currently being produced by fossil fuels, so electricity will have a CO2 amount associated per kW. What can be done to burn less fuel in your furnaces or ovens, which directly relates to reducing CO2?

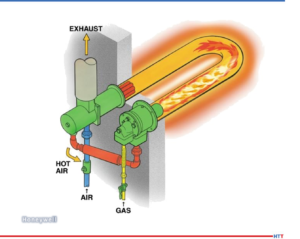

Tune Your Combustion Systems

Source: Honeywell

Over time combustion systems drift and are not at their optimum air/fuel ratio. By simply tuning your burner system on a routine basis, you can fire at the optimum air/fuel ratio for the process and be as efficient as possible. For example, if a furnace is firing on natural gas, operating at 1800°F, and currently operating at 35% excess air, tuning your burners to 10% excess air could save approximately 15% in fuel consumed. The fuel costs will be reduced, and the resulting CO2 will be reduced by that same percentage!

Maintain Your Furnaces/Ovens

A simple review of your furnaces or ovens to observe any hot spots, openings, faulty seals, or refractory issues will identify areas that will cause your systems to operate less efficiently, thus using more energy. Repairing these problems and consistently maintaining them will have the systems running more efficiently and producing as little carbon as possible.

Upgrade Your Firing Systems To Be More Efficient

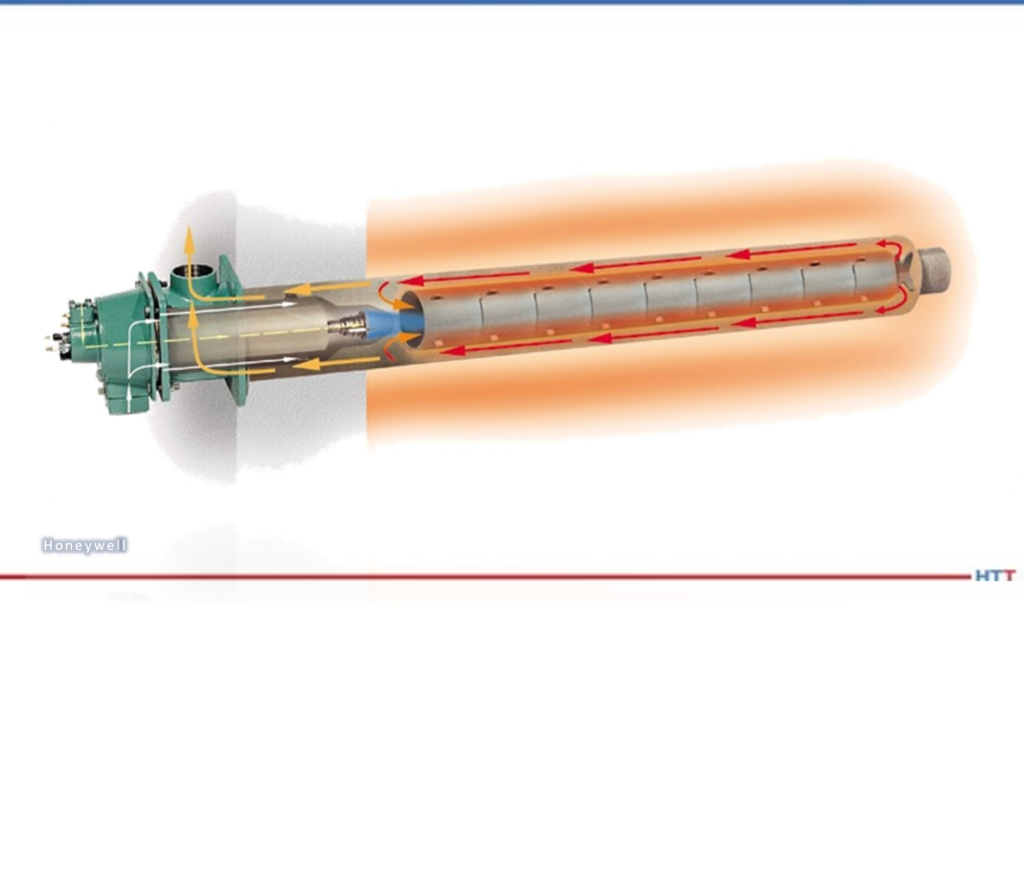

Source: Honeywell

Incorporating preheated combustion air into furnace combustion systems can significantly reduce fuel consumption and therefore the resulting carbon. The two main methods for introducing hot air into a combustion system are recuperation and regeneration. The most popular air preheating method in heat treating applications is recuperation. For a direct fired furnace, this can take the form of a central stack recuperator or self-recuperative burners. Self-recuperative burners have grown in popularity in recent years as they get rid of the need for hot air piping, recuperator maintenance, and most are often pulse fired, which will not only maximize efficiency but also promote temperature uniformity in the furnace and often be lower in emissions. For indirect fired (radiant tube) furnaces, you can apply/add a plug recuperator to an existing cold air fired burner in a furnace that has a U or W-tube to preheat the combustion air or apply self- recuperative burners installed in Single-Ended Radiant (SER) tubes to optimize your furnace firing. The SER tube material can be upgraded to silicon carbide which allows higher temperatures/flux rates that can provide the opportunity to increase throughput and reduce the possible CO2 per cycle.

Combustion air preheating can result in energy savings of close to 25% over cold air combustion.

Renewable Fuels/Hydrogen

Renewable fuels or hydrogen have entered the scene as these are fuels that contain little or no carbon. So, no carbon in the fuel means no CO2! These fuels present an excellent opportunity to significantly reduce carbon. Hydrogen has been of interest because it has the opportunity to be a zero-carbon industrial fuel when produced with renewable energy such as wind, solar, hydro, or nuclear power. As these methods become more prevalent, they bring down the price of hydrogen and increase its availability. This could be a significant driver to greatly reduce CO2 in thermal processes. These topics as well as many others are being discussed in an on-going Sustainability Webinar series hosted by IHEA to provide education and insight into the ever-changing sustainability landscape.

Source: Honeywell

About the author:

Brian Kelly is manager of Application Engineering for Honeywell Smart Energy and Thermal Solutions (SETS) and current president of the Industrial Heating Equipment Association (IHEA).