Tenaris OCTG Production Restarts In-House Heat Treating

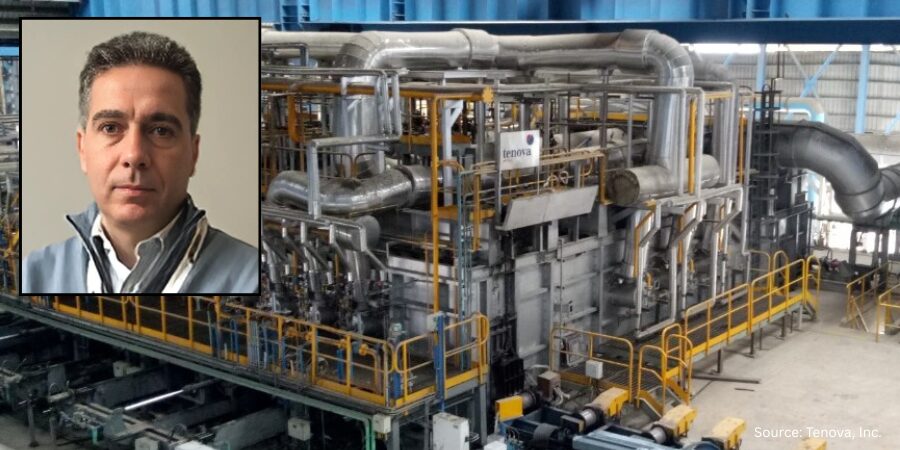

Global pipe manufacturer Tenaris has reactivated quenching and tempering operations at its Koppel, Pennsylvania facility, restoring a critical stage of in-house heat treating capacity that supports domestic oil country tubular goods (OCTG) production for the U.S. energy sector. The restart reinforces supply chain reliability for clients requiring high-performance steel pipe.

President

Tenaris U.S.

The reactivation follows Tenaris’s broader investment in its Pennsylvania operations and coincides with the reopening of the adjacent steel mill. “Reopening the heat treatment and finishing lines in Koppel reinforces the strength of our domestic production capabilities for our clients across the U.S.,” says Guillermo Moreno, Tenaris U.S. President. “Koppel remains a cornerstone of our U.S. operations, allowing us to deliver high-quality steel products that support U.S. energy and industrial needs.”

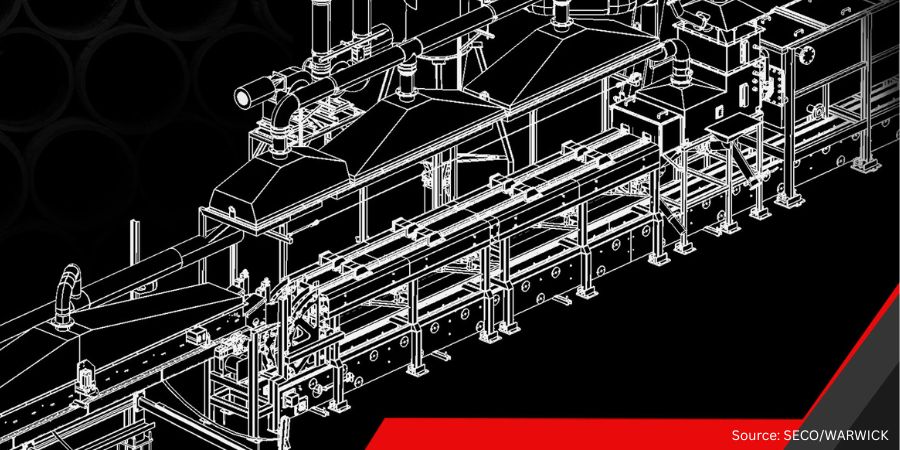

Tenaris operates an integrated steel pipe manufacturing system across Pennsylvania and Ohio. At the Koppel facility, steel billets are produced in an electric arc furnace and shipped to Ambridge, Pennsylvania, where they are rolled into seamless OCTG to client specifications. The pipes are then returned to Koppel for quenching and tempering, followed by finishing, nondestructive testing, and inspection.

In the final stage of production, the pipes are sent to Tenaris’s Brookfield, Ohio, facility for threading and final inspection before shipment to oil and gas clients across the United States. With the Koppel heat treatment lines back online, Tenaris strengthens its U.S. production capabilities and continues delivering high-performance steel products for energy and industrial applications.

Press release is available in its original form here.

Tenaris OCTG Production Restarts In-House Heat Treating Read More »