JUPALCO Expands Aluminum Coil Annealing Capacity

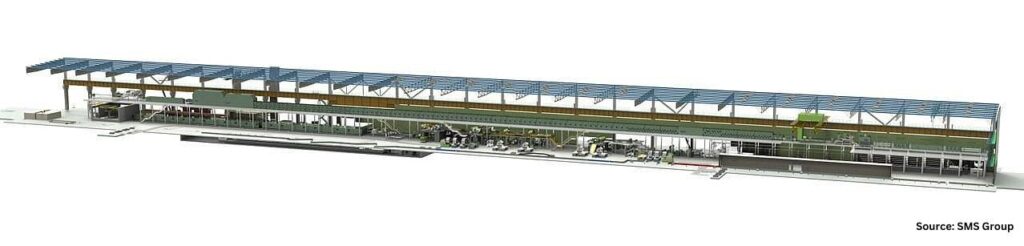

Jupiter Aluminum Industries (JUPALCO), part of the Jupiter Group, has ordered two aluminum coil annealing furnaces to support production at its rolling mill operations, strengthening capacity and consistency for flat-rolled aluminum products serving automotive, construction, and packaging markets. The investment reflects continued global demand for advanced aluminum heat treating capacity.

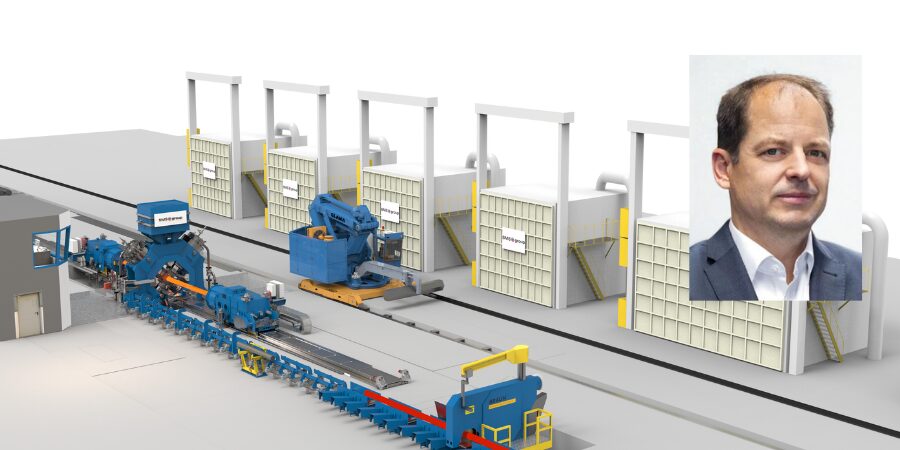

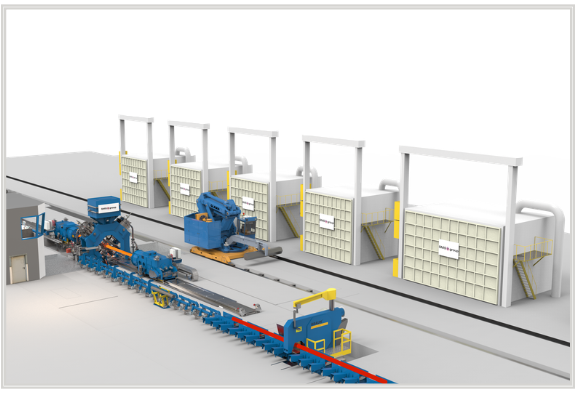

The furnaces, slated for installation at JUPALCO’s rolling mill operations in India, are designed to handle large aluminum coils, with a maximum outside diameter of 2,600mm, widths up to 2,300mm, and a total gross load capacity of 93.6 metric tons. Multi-zone chamber configurations and advanced control systems are engineered to deliver precise temperature uniformity and repeatable annealing results across high-volume production runs.

Vice President of Aluminum and CAB Products Segment

SECO/WARWICK

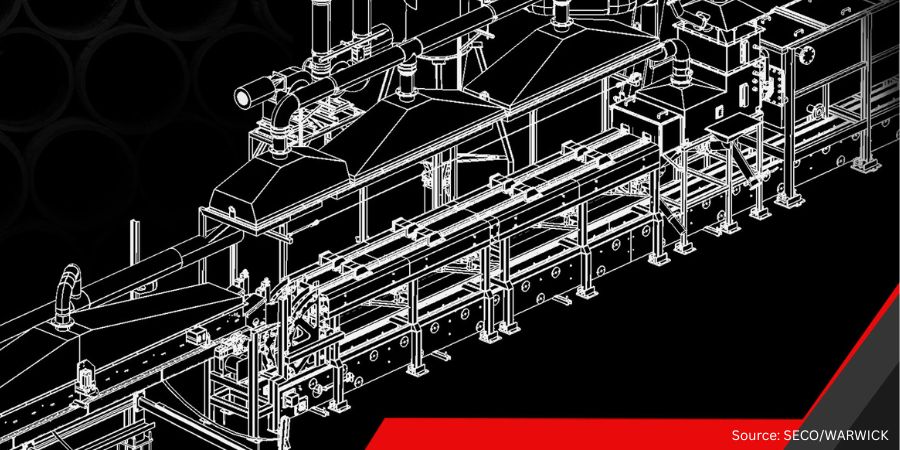

The equipment will be supplied by SECO/WARWICK, a furnace supplier with North American locations, and incorporates the company’s Vortex 2.0 aluminum coil annealing technology, which uses high-velocity airflow to improve heat transfer, shorten cycle times, and reduce the risk of localized overheating. The design also supports energy-efficient operation while maintaining tight temperature tolerances throughout the annealing process.

According to Piotr Skarbiński, vice president of the CAB and Aluminum Products Segment at the SECO/WARWICK Group, the Vortex 2.0 is designed with a system of appropriately directed nozzles that support consistent aluminum processing while reducing cycle times and energy consumption.

The Indian market for flat-rolled aluminum products is growing rapidly, with its value expected to rise from USD 4.5 billion in 2025 to USD 12 billion by 2035. Investments by manufacturers like JUPALCO in new rolling mills highlight both the domestic growth potential and the wider demand for advanced annealing technologies in global markets.

Press release is available in its original form here.

JUPALCO Expands Aluminum Coil Annealing Capacity Read More »