Achieving High Furnace Production

![]() Your system is great, but is your furnace performing the best it can? In this Original Content article from Alberto Cantú, vice president of Combustion, Control and Services at Nutec Bickley, learn three key performance evaluation methods and five tips to increase productivity. Check out how implementing these changes applies in the brief case study at the end.

Your system is great, but is your furnace performing the best it can? In this Original Content article from Alberto Cantú, vice president of Combustion, Control and Services at Nutec Bickley, learn three key performance evaluation methods and five tips to increase productivity. Check out how implementing these changes applies in the brief case study at the end.

VP Combustion, Control and Services

Nutec Bickley

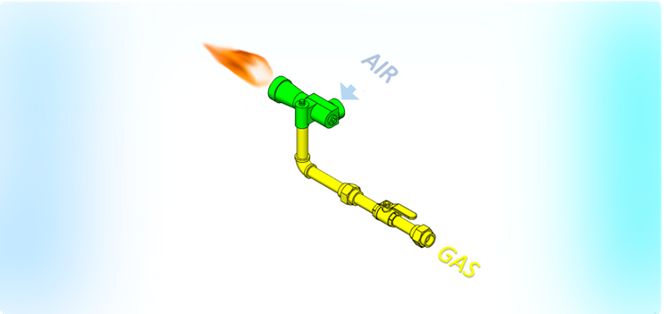

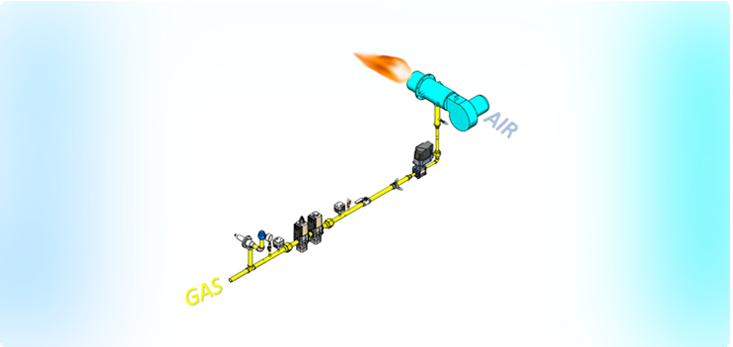

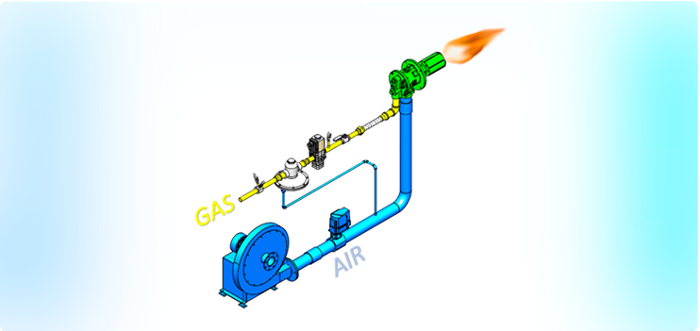

Adjusting furnace burners not only saves fuel, but can increase the return on investment (ROI) of heat treating operations when confronted with:

- Problems reaching the desired temperature

- Longer than expected processing cycles

Every kilogram of product that we fail to create has a corresponding impact on the ROI that we are able to obtain.

Adjusting your equipment may be the solution to reaching your ideal temperature, make your parts heat faster, and increase production. Learn more in this article.

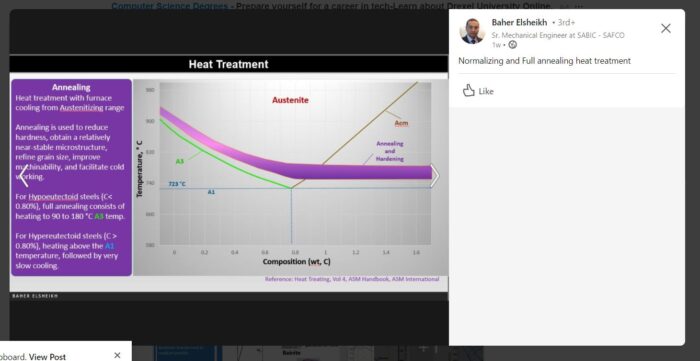

Performance Evaluation Methods

We recommend the following:

1. Establish a benchmark of standard values in your industry to evaluate your performance in each furnace/process and discover the opportunities for improvement.

Example: For a reverberatory aluminum furnace, consumption should be between 2,000-2,500 British Thermal Unit (BTU)/pound. On the other hand a stack melter is in the order of 1,000 BTU/pound. (See “A Melt Performance Comparison” for example.)

2. Measure the oxygen level inside the industrial furnace to determine the current air/gas ratio and whether there is any infiltration.

If oxygen levels are high, the furnace will consume more fuel, flames will be cooled, and you run the risk of oxidizing your product (in the case of metals). If you introduce the correct volume of air, there should be no oxygen in the furnace, since it is all consumed in the combustion process.

This measurement can be conducted extremely rapidly without being expensive or invasive and will allow you to evaluate the status of your processes. If you measure it in-situ, which is more expensive, you will get a consistent reading. Alternatively, you can measure it manually with an oxygen probe. Doing it manually should take no more than a couple of minutes.

This measurement can be conducted extremely rapidly without being expensive or invasive and will allow you to evaluate the status of your processes. If you measure it in-situ, which is more expensive, you will get a consistent reading. Alternatively, you can measure it manually with an oxygen probe. Doing it manually should take no more than a couple of minutes.

3. Obtain a thermographic image in order to determine the furnace wall temperature, to confirm the state of the insulation, and to verify that there are no relevant heat leaks that represent a danger to the furnace or its instruments.

It is vital to check your entire system since sometimes the burners are correctly adjusted, but there are leaks in the doors or walls. The picture to the right shows leaks through the furnace door. If pressure is negative, this becomes an infiltration and you will see more oxygen in the furnace and, therefore, more fuel consumption.

Tips for Optimizing Operation of Your Furnaces

Some recommendations to increase furnace productivity are:

- Modify the heating curve by adjusting the set point and increasing the initial temperature value to reach the required level faster.

- Perform ramp-type reductions in temperature to increase production by shortening cycles.

- Space out the individual parts in the load for greater heat transfer. Increasing the transfer area decreases the heating time and allows us to produce more.

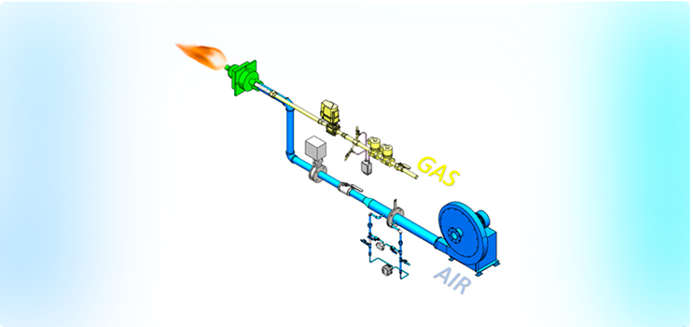

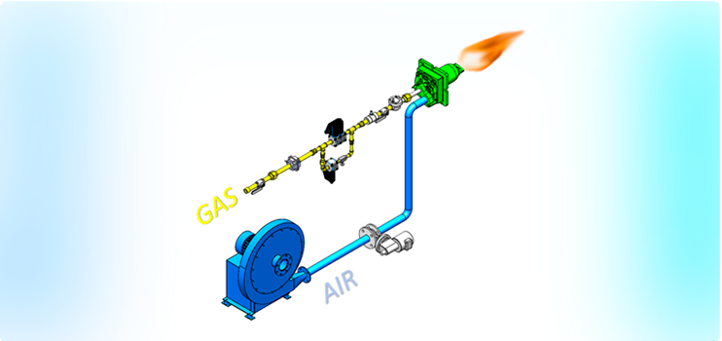

- Nutec Bickley’s IMPS system intersperses the use of burners to optimize heat transfer thanks to the principles of convection and radiation phenomena.

- The use of regenerative and recuperative burners in radiant tubes makes it possible to improve the system’s energy efficiency by taking advantage of residual heat from the process.

Implementation

To conclude, here is an example of a customer with an aluminum homogenizing furnace where time was decreased 20% by modifying the temperature curve:

About the Author: Alberto Cantú is the vice president of Combustion, Control and Services at Nutec Bickley. Cantú has more than sixteen years of professional experience, including in the food industry, CFD software consultancy, heating and thermal treatment processes, and general manufacturing industry. He has written nine official publications in a variety of journals about residence time distribution and analyzing different designs. Cantú is also a well-recognized member of Heat Treat Today’s 40 Under 40 Class of 2020; read more about him here.

All images provided by the author.

Achieving High Furnace Production Read More »