39 Heat Treat News Chatter Items To Keep You Current

Heat Treat Today offers News Chatter, a feature highlighting representative moves, transactions, and kudos from around the industry. Enjoy these 39 news bites that will help you stay up to date on all things heat treat.

Heat Treat Today offers News Chatter, a feature highlighting representative moves, transactions, and kudos from around the industry. Enjoy these 39 news bites that will help you stay up to date on all things heat treat.

Equipment Chatter

- The precision forging manufacturer Jiangsu Pacific Precision Forging Company has placed an order with SMS group for a fully automatic MP 3150 eccentric closed-die forging press. Pacific Precision will be able to forge aluminum chassis components on a much larger scale. This new expansion provides Pacific Precision with access to the growing automotive market segment for more lightweight designs.

- A commercial heat treater in Mexico purchased a third vacuum furnace from SECO/WARWICK Group.

- Ecocat India, a catalyst manufacturer, has ordered an advanced technology vacuum gas cooling furnace from SECO/WARWICK. The system will carry out brazing and annealing processes.

- Several new CAB lines have been ordered from SECO/WARWICK to be delivered to manufacturers in China. Two companies specifically chose EV/CAB lines while another manufacturer purchased a CAB line.

- SECO/WARWICK delivered two CAB lines and one universal chamber furnace for aluminum brazing to an automotive manufacturer in China. The systems will braze large-size coolers for vehicle batteries.

- Oetzbach Edelstahl GmbH, a hardening plant, has purchased a third furnace from SECO/WARWICK.

- A Swiss commercial heat treater ordered a brazing furnace to be used for nickel and silver from SECO/WARWICK.

- Tenova LOI Thermprocess has completed the production optimization of a new Twin-Chamber Melting Furnace (TCF®) at E-Max Billets in Kerkrade, the Netherlands.

- An Asian thread rolling die conglomerate selected a SECO/WARWICK vacuum furnace. The Vector® will be used for vacuum hardening and tempering fastener dies.

Company and Personnel Chatter

- Hubbard-Hall has expanded its product offering and customer resources by acquiring the assets of Torch Surface Technologies, a specialty chemical company based in Whitmore Lake, MI.

- New simulation software is being launched at CENOS Simulation Software. The application portfolio expands with some new electromagnetic case software apps. The first apps will be launched in Q4 or a little later.

- Solar Atmospheres of California announced it has been awarded the approval to process parts for Lockheed Martin (LMCO) owned Sikorsky. The Sikorsky approval adds to the existing LMCO process specifications held for vacuum heat treatment of titanium, nickel alloys, and stainless steel per AMS 2801, AMS 2774, AMS 2759/3, and others.

- Nel Hydrogen US, a subsidiary of Nel, has entered into a joint development agreement with General Motors to help accelerate the industrialization of Nel’s proton exchange membrane (PEM) electrolyzer platform. The two companies are looking to enable more cost competitive sources of renewable hydrogen.

- The Supervisory Board of thyssenkrupp AG extended the appointment of Oliver Burkhard by five years. Burkhard has been a member of the Essen-based group's Executive Board since February 2013, Thyssenkrupp AG director of Labor since April 2013, and additionally CEO of thyssenkrupp Marine Systems since May 2022.

- Joe Coleman, cyber security officer of Bluestreak Consulting™, has earned his Cyber AB CMMC Certification as a Registered Practitioner (RP). CMMC is a U.S. Department of Defense (DoD) program that applies to Defense Industrial Base (DIB) contractors.

- CG Thermal welcomes associate process engineer Signe Laundrup to the Process Systems Group. Laundrup is a 2021 chemical engineering graduate from the University of California, San Diego. Her background is in manufacturing and research and design.

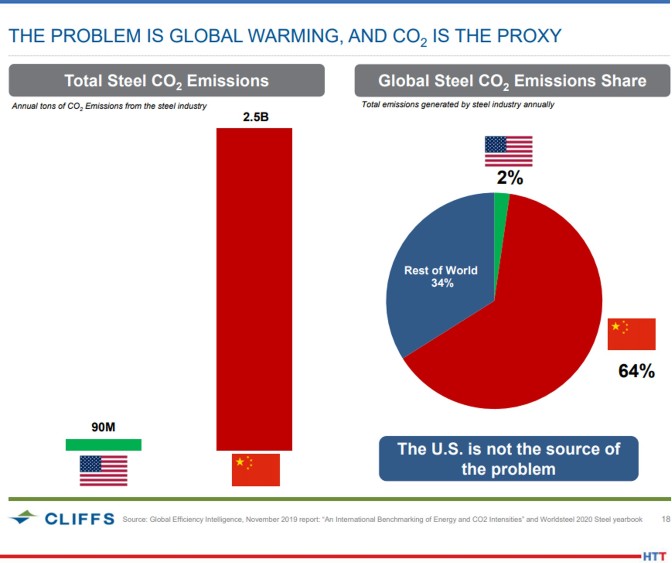

- Tata Steel signed a memorandum of understanding with SMS Group to reduce carbon emissions at Tata’s integrated steel plants across India.

- Two heat treat technology companies integrate: C3 Data’s real-time pyrometry compliance software enables digital uploading of certificate data of all TT Electronics.

- Ipsen Japan announced the addition of Mr. Masakazu Kanaka in the role of customer service director. Kanaka is responsible for the growth of all Ipsen Japan customer service business, which includes retrofits, parts, and service. He will oversee the aftermarket sales team and field service engineers.

- Solar Atmospheres of California announced Honeywell approval to heat treat austenitic steels, martensitic steels, pH steels, tool steels, nickel alloys, cobalt alloys, titanium alloys, and magnetic alloys.

- Aluplast – ZTG, an Altest company, recently expanded its production capacity with a second Nitrex nitriding system. The second furnace, a model N-EXT-612, is capable of processing a load of extrusion dies weighing up to 1300lbs.

- Solar Atmospheres of Michigan is pleased to announce the addition of Chris Molencupp as their new sales manager.

- Metal Exchange Corporation announced that Matt Rohm, current President and Chief Operating Officer (COO), will be promoted to Chief Executive Officer (CEO) of Metal Exchange Corporation effective January 1, 2023. At that time, current CEO Rick Merluzzi will assume the title of executive vice chairman, serving as an advisor to executive chairman, Mike Lefton, on key strategic initiatives for the organization, through the end of 2023.

- Quintus Technologies joins the newly opened Application Center at RISE to support further development of additive manufacturing. The AM Center will also include the Quintus press model QIH 15L-2070.

- Abbott Furnace Company announced that it has partnered with Obsidian Technical Group for sales and service support across much of the eastern United States.

- Robert Roth announced the appointment of Nelson Sanchez as RoMan’s new president, effective January 1, 2023. Sanchez is the first non-family member to hold the office.

- Hubbard-Hall hired Aaron Mambrino as chief financial officer. Her expertise lies in driving process changes to create operational synergies, developing strategic partnerships, and LEAN manufacturing.

- John Savona, vice president of Americas Manufacturing and Labor Affairs, Ford Blue, will retire on March , after more than 33 years. Bryce Currie will step into the role.

- AFC-Holcroft welcomed employees and their families, company retirees, and invited guests to view their newly renovated building as part of an open house.

- Solar Atmospheres of California participated in the “Spark of Love” toy drive in coordination with the San Bernardino County Fire Department.

- Raytheon Technologies expands Bengaluru operations with opening of Pratt & Whitney India Engineering Center. The facility is co-located with Pratt & Whitney’s India Capability Center and Collins Aerospace engineering and global operations centers.

- Lucifer Furnaces in Warrington, PA, a manufacturer of heat treating furnaces and ovens for the last 80 years, has added Brett Wenger to its leadership team as vice president of sales.

Kudos Chatter

- Global Thermal Solutions celebrates 15 years in Mexico.

- Hitchiner Manufacturing receives Nadcap Accreditation.

- Ipsen USA announced that 2023 represents a milestone anniversary. This year marks 75 years since Harold Ipsen founded the company.

- Desktop Metal is sponsoring on a new season of BattleBots. The completely rebuilt robot is aided by the design freedoms and fast turnaround times of metal 3D printing.

- Solar Atmosphere’s Michigan and Western Pennsylvania facilities have recently been awarded Nadcap Merit status for vacuum heat treating and brazing.

- In September, the Swiss Steel Group (SSG) held the 1st Hydrogen Symposium at the Henrichshütte Iron and Steel Works in Hattingen. Speakers from academia, business, and politics held lectures in four sessions.

- Borikengineers, a team mentored by Pratt & Whitney employees in Puerto Rico, has advanced to the Qualifiers’ Finals Competition in the FIRST Tech Challenge DC Qualifier. The team won the Judges Choice Award.

Heat Treat Today is pleased to join in the announcements of growth and achievement throughout the industry by highlighting them here on our News Chatter page. Please send any information you feel may be of interest to manufacturers with in-house heat treat departments especially in the aerospace, automotive, medical, and energy sectors to sarah@heattreattoday.com.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

39 Heat Treat News Chatter Items To Keep You Current Read More »