Source: AMPOWER

There is so much to learn in so little time, but if you are at all interested in additive manufacturing (AM), you will want to check out this new study.

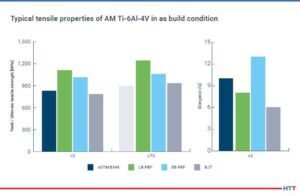

This Heat Treat Today’s Best of the Web feature is full of scholarly findings presented in an easily accessible PDF for free. Three insights that the study elaborates on are: Titanium represents largest share of materials in AM; HIP cycles are not optimized for AM; and part performance may be increased by optimized HIP cycles. The study was developed by Dr.-Ing. Maximilian Munsch, Matthias Schmidt-Lehr, and Dr.-Ing. Eric Wycisk (pictured above in that order).

You can check out these summary insights of the study, or download the complete study for free at “Additive Manufacturing Material Performance Optimization: Increasing properties of Ti-6Al-4V parts by AM specific HIP treatments.”

An excerpt: “To increase the part performance hot isostatic pressing (HIP) is commonly used for highly demanding applications and has become a common post- process for titanium AM parts as well. However, the typically used temperature-pressure-cycles for AM are derived from HIP processes originally used for casting parts.”

All images were sourced from www.am-power.de/.