One of the great benefits of a community of heat treaters is the opportunity to challenge old habits and look at new ways of doing things. Heat Treat Today’s 101 Heat Treat Tips is another opportunity to learn the tips, tricks, and hacks shared by some of the industry’s foremost experts.

One of the great benefits of a community of heat treaters is the opportunity to challenge old habits and look at new ways of doing things. Heat Treat Today’s 101 Heat Treat Tips is another opportunity to learn the tips, tricks, and hacks shared by some of the industry’s foremost experts.

For Heat Treat Today’s latest round of 101 Heat Treat Tips, click here for the digital edition of the 2019 Heat Treat Today fall issue (also featuring the popular 40 Under 40).

Today’s tips are the 1 – 2 – 3! They come to us from Dry Coolers with a word on cooling system growth capability; Bloom Engineering Company Inc. on the importance of careful spending; and Rick Kaletsky, Safety Consultant about clear content labeling.

Heat Treat Tip #1

Buy a Cooling System Capable of Growth

Plan for future growth. It is more cost effective to provide additional capacity while equipment is being installed. Simple planning for the addition of future pumps (e.g. providing extra valved ports on tanks) and space for heat transfer equipment (e.g. pouring a larger pad or adding extra piers) can save considerable money down the road with little upfront expenditure. Consider installing one size larger piping for the main distribution supply and return; if this is not possible, make sure you can add an additional piping run on the hangers you will install now. Above all, be sure to include all necessary drains, vents, isolation valves, and plenty of instrumentation. These items are critical aids in maintenance, troubleshooting, and future system expansion. (Dry Coolers)

Heat Treat Tip #2

Never Go Cheap on These Two Things

There are 2 things in life you should never go cheap on: Toilet paper and combustion equipment! When upgrading or looking at new systems, spend the money to do it right. Designing on the cheap will only lead to operational and maintenance headaches. And trying to reuse the ancient artifacts when upgrading just to save a buck will cost you 10x that down the road. You don’t have to break your budget to do a quality job! (Bloom Engineering Co. Inc.)

Heat Treat Tip #3

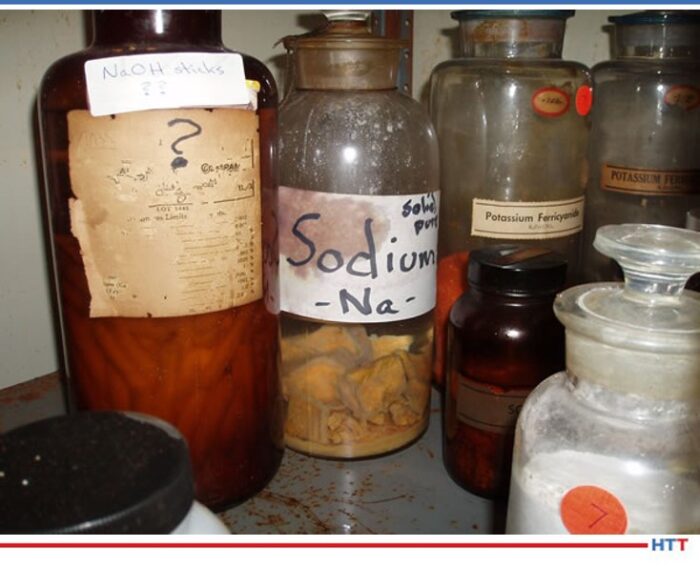

Container Clarity Counts!

Assure that container label wording (specifically for identifying chemical contents) matches the corresponding safety data sheets (SDS). Obvious? I have seen situations where the label wording was legible and accurate and there was a matching safety data sheet for the contents, but there was still a problem. The SDS could not be readily located, as it was filed under a chemical synonym, or it was filed under a chemical name, whereas the container displayed a brand name. A few companies label each container with (for instance) a bold number that is set within a large, colored dot. The number refers to the exact corresponding SDS. (Rick Kaletsky, Safety Consultant)