Orthodontic Industry Purchases Blue M Convection Oven from TPS

Thermal Product Solutions (TPS), a global manufacturer of thermal-processing equipment, announced the shipment of a Blue M Ultra-Temp Standard Convection Oven to the Orthodontics industry. The convection oven will be used for a metal injection molding debind process at temperatures of 390°F and 1050°F.

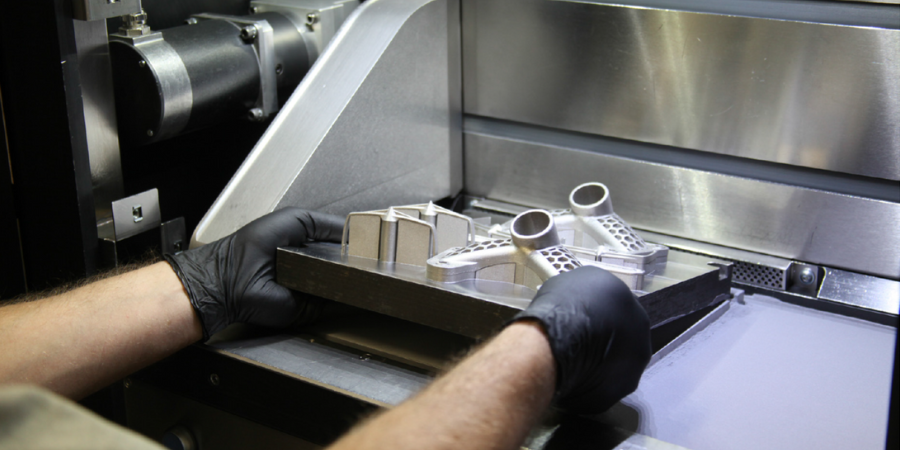

The Blue M oven work chamber is 48” W x 24” D x 36” H and has a maximum temperature rating of 1300°F. The customer’s parts will be placed on ceramic trays then run through the debind cycle that usually lasts 14 to 16-hour cycle. The process off gasses some non-hazardous fumes that condense into a form of wax. The parts are loaded into the oven via a lift truck.

The oven has a powered exhaust with VFD for pulling out non-hazardous fumes coming from the products during the de-binding process. The VFD will enable the customer to adjust the exhaust motor speed to reduce or increase the exhaust flow rate.

Unique features of these Blue M ovens include:

- Powered exhaust

- Reinforced chamber floor to hold up to 500-lbs distributed load

- 6-inch high angle iron floor stand to raise the oven and allow customer to insert their lift truck under the oven to load their product into the oven work space

Orthodontic Industry Purchases Blue M Convection Oven from TPS Read More »

To meet Schafer Gear Works’ growing demand for high-precision commercial aviation shafts and gears, the company recently moved its Fort Wayne, Ind., operations to its larger production facility in South Bend, Ind. “Acquisition of new, state-of-the-art equipment at our South Bend plant and the ability to better leverage our gear manufacturing expertise led to the transfer,” said Paresh Shah, operations manager for the South Bend facility. The transition was seamless and the plant now produces precision-critical shafts and small-diameter gears with tolerances to 0.0004” and microfinishes to 16 RMS.

To meet Schafer Gear Works’ growing demand for high-precision commercial aviation shafts and gears, the company recently moved its Fort Wayne, Ind., operations to its larger production facility in South Bend, Ind. “Acquisition of new, state-of-the-art equipment at our South Bend plant and the ability to better leverage our gear manufacturing expertise led to the transfer,” said Paresh Shah, operations manager for the South Bend facility. The transition was seamless and the plant now produces precision-critical shafts and small-diameter gears with tolerances to 0.0004” and microfinishes to 16 RMS.