40 Under 40 Highlight: Christina Somogye

In 2018, Heat Treat Today introduced one of its most popular features, the 40 Under 40 Awards for young, up-and-coming talent in the North American heat treat industry. Click here for the 2018 recipients. Heat Treat Today is posting occasional features of some of the 2018 recipients in anticipation of the 2019 40 Under 40 awardees to be presented in September (nominations are being accepted here). Today we feature Christina Somogye of Akron Steel Treating Company.

Christina Somogye

Christina Somogye

Akron Steel Treating Company

VP of Administration and Operations; Shareholder in ASTC

Christina Somogye was nominated from within Akron Steel Treating Company. The following was provided by the nominator:

Christina graduated with a degree in mechanical engineering from The Ohio State University and has also completed the MTI “Yes” Program. She has earned respect from her fellow employees, the customers and the vendors at Akron Steel Treating, being wise beyond her years. In January [2018], she purchased a 10% interest in ASTC and is an integral part of the succession plan. Christina balances her responsibilities at Akron Steel Treating Company with being wife to Aaron and mother to her 3-year-old daughter, Olivia. The family resides in Sarnia, Ontario.

Christina Somogye follows three generations of steel treaters at Akron Steel Treating Company, which celebrated its 75th anniversary in 2018. Her great-grandfather, Prosper P. Powell, founded the company in 1943, and her father, Joe Powell, is currently at the helm. In this way, Christina has grown up in the environment of metallurgy, steel treatment and manufacturing, and heat treating operations. Asked what interests her about the industry that compelled her to stay with the family business, she says, “I enjoy evaluating our racking procedures to optimize load size and ensure uniformity throughout the load with an ergonomic work set up for our employees.”

With the changes in the industry due to technology, new materials, etc., Christina is enthusiastic about the way ASTC is seeking innovative methods, equipment and processes to keep up.

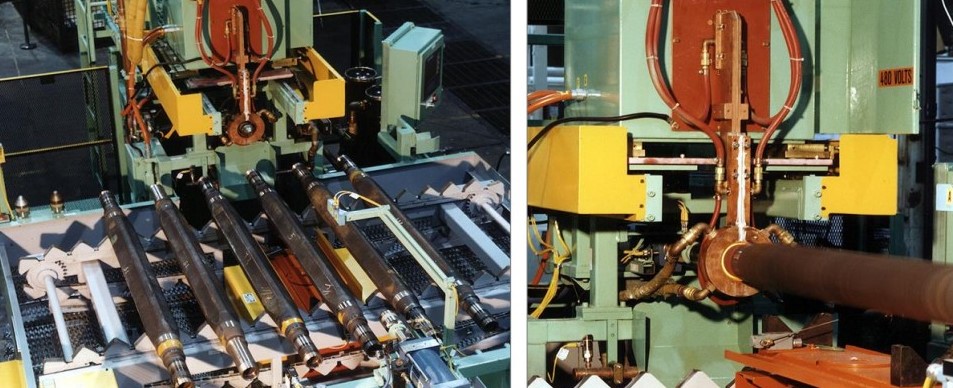

“ASTC, especially our President, Joe Powell, has been very passionate about new heat treating process technology,” she says. “We are a licensee of the IntensiQuench® process. We work with fabricators to build new and unique equipment for ourselves and to prove out new heat treatment processes. Akron Steel Treating Company is the ‘skunk works’ for IHTS Akron, Joe’s heat treat and metallurgical consulting company.”

Heat treating is an industry that offers a unique path to invention, innovation, and discovery. Christina agrees that “there are many opportunities in large and small heat treating companies (commercial and captive) as well as the equipment, alloy, material suppliers and service industries that serve the heat treating companies. The knowledge of senior industry members is ready to be passed on to the next generation with tremendous opportunities for growth and technical expertise. Small, privately held businesses and large, multi-facility companies have the need to pass down this tribal knowledge for their continued success.”

Click here for the 2018 recipients. To nominate someone for the Class of 2019 40 Under 40, please click here.

40 Under 40 Highlight: Christina Somogye Read More »