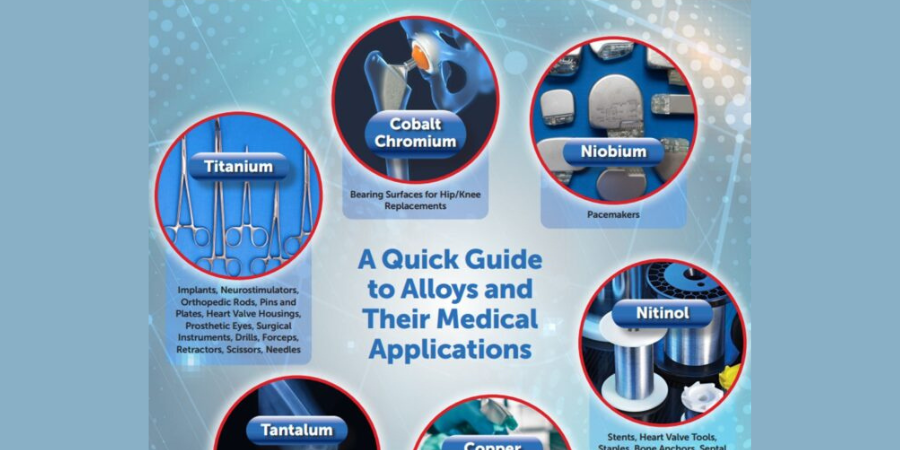

A Quick Guide to Alloys and Their Medical Applications

Do you know what are the most popular alloys in the medical market? What are their applications? This medical alloys reference graphic gives a quick overview of alloys and their specialized uses in the medical industry.

Ask average people walking along the street what metal/alloy comes to mind when they think of medical uses - things like hip and shoulder joints, the orthodontia their kids might wear, the forceps used to remove stitches - they might come up with the answer "titanium." While this certainly is correct, there are lots of other metals and metal alloys that are used in the medical industry. They probably wouldn't answer "nitinol," a titanium alloy. Nitinol is actually used in the aforementioned braces! Nitinol can be found in other things too: stents, staples, septal defect devices, etc. Take a look at the graphic to see what all these alloys, in fact, can do; you might be surprised!

Such important implements, devices, and components that are used in and on the human body need to be durable and reliable. These medical pieces can improve the quality of life (to put it mildly) or actually save a life (to put it dramatically). Some of these alloys are actually used in and around the heart and blood vessel system! Only the best of the best will do to make up these medical items; lives are literally preserved and saved with them.

What alloys have you found in medical applications? Maybe you have experience with a loved one or yourself incorporating one of these medical pieces in your life? Are you a heat treater involved in the making of these products? Let Heat Treat Today know in the Reader Feedback.

Download the full graphic by clicking the image below.

Source: Heat Treat Today

A Quick Guide to Alloys and Their Medical Applications Read More »