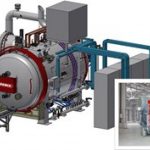

VIM Furnace Enlisted in Purdue Project to Develop New Composite Material for Efficient Energy Use

Purdue University recently turned to an integrated furnace manufacturer for equipment to be used in an innovative project developing a new material and manufacturing process that would use solar power — as heat energy — more efficient in generating electricity.

RETECH, a SECO/WARWICK company, has provided a vacuum induction melting (VIM) furnace for the project’s research to increase efficiency of solar-generated electricity. The furnace can easily handle a wide range of materials used in everything from automotive and consumer products to critical, high-value equiax, directionally solidified or single-crystal aerospace parts.

According to the U.S. Energy Information Administration, solar power accounts for 1.3 percent of U.S. electricity. If the cost of electricity generation and energy storage for use on cloudy days and at nighttime were cheaper, the percentage of electricity generation by renewable energy sources – like solar power – would be higher.

See Retech’s video on the use of a new composite material that harnesses the sun’s heat for cheaper renewable energy: https://youtu.be/PMC3EE19ouw