Heat Treat Radio #30: Dr. Shahrukh Irani on Job Shop Lean

Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Audio: Dr. Shahrukh Irani of Lean & Flexible LLC

In this conversation, Heat Treat Radio host, Doug Glenn, interviews Dr. Shahrukh Irani of Lean & Flexible LLC about how manufacturers with in-house heat treat might implement the Job Shop Lean concept, thereby increasing profits and efficiencies. Listen to learn whether your company might benefit from examining its processes and making parts of its daily operations more lean, flexible, and ultimately more profitable.

Click the play button below to listen.

Transcript: Dr. Shahrukh Irani of Lean & Flexible LLC

The following transcript has been edited for your reading enjoyment.

DG: We're going to discuss how manufacturers with in-house heat treat might implement lean manufacturing concepts to increase profits and efficiencies. But first, I'd like to give a shout-out to John Tirpak, who I've know for many years, and his recommendation to talk to today's guest, Dr. Shahrukh Irani. I first met John when I was involved with the creation of a magazine called Forge, a publication that is still published by BNP media and serves the North American forging industry. John is a very accomplished engineer, metallurgist, and C level management guy with a lot of energy and vision. He knows the metals, forging, and heat treat industry, and it is on his recommendation that we're talking to Dr. Irani today, so thanks, John.

Dr. Irani is the president of a one person consulting company, Lean & Flexible LLC. Lean manufacturing isn't a topic discussed too frequently in the heat treat world, but there are significant benefits to be gained by doing so. That's why today's conversation with Dr. Irani should be of significant benefit to you, especially if you're a high mix/low volume manufacturer, as opposed to a low mix/high volume manufacturer. While the bulk of heat treat today's audience are manufacturers with their own in-house heat treat departments, many of these departments heat treat a wide variety of parts and therefore qualify as high mix, low volume producers. Our friends in the commercial heat treat world will also find this episode beneficial since most of their business is built around high mix/low volume job shop type work.

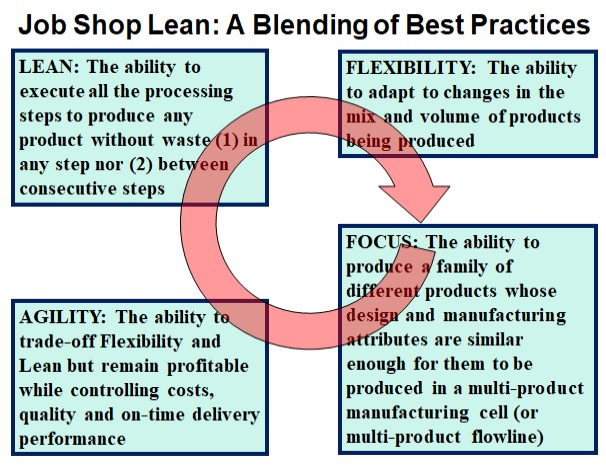

SI: My company's name is Lean and Flexible. I am just a one person consulting gig. The name pretty much tells everybody what I think needs to be done. When you are high mix/low volume, (especially if you are job shop, but not necessarily job shop), you want to be lean, which is waste-free, efficient; but then you want to be flexible. You want to be able to do a whole variety of parts in different quantities. Everybody can talk lean; but when you try to become flexible, all of those things that your favorite consultant taught you to believe kind of work against you. You have to be agile. Agile is the speed with which you can change your world and do different types of heat treat. That's pretty much what my consulting company does.

DG: Very briefly, with respect to your background, I know that you've been in academia for a while, but when you met John, you spun off this new company. Tell us briefly about your academic background, and also if you don't mind, tell us about maybe any interaction with Toyota, which, of course, is the big company when it comes to lean.

SI: I began my academic career after I got my PhD in 1990 and straight for about 22 years, from 1990 to 2012, I was in academia. I read that book, Lean Thinking, which talked about Toyota in 1999, and it really got me interested. What is called lean, or what is called the Toyota Production System, is just industrial engineering, but very hands on. Toyota basically figured out industrial engineering the way that the rest of us, especially in America, never did. And that's basically what lean is--Toyota style industrial engineering.

When I began in 2003 when John met me, his challenge to me was, look, research is fine, but I deal with custom forge shops. They make batches of 50 and 100. They don't make 200,000 cars a year. So throw all that Toyota flavor of lean out the window. You give me some lean stuff that I can benefit these custom forging suppliers who send parts to the DOD. That's how this whole idea of job shop lean was born. Industrial engineering, which is the math and the science, and then blended with this very hands on, very practical industrial engineering that came out of Toyota. I think that's very key. I don't think the world recognizes that we actually teach a profession, that there are professionals called industrial engineers, but how do they practice the Toyota method of industrial engineering, that that education is just academic.

DG: I saw a statement on your website that maybe ties in here. Maybe you could expound on this a little bit. I thought it was a very interesting statement. You have a statement on your website that says this: "Where industrial engineering meets the Toyota production system." Can you expound on that a little bit? Exactly what does that mean, and why you have that on your website?

SI: Sure. Look at me. I was an academic for 22 years. I never worked at Toyota, so I never had the benefit of their expert lean implementers teaching me. But I was an industrial engineer. So when I read things like value stream mapping and one piece flow and a little Japanese was Kaizen, Jidoka, Poka Yoke, Kanban; when you distill those practices down, at the bottom of it is pure industrial engineering. Like when you smelt iron, the slag comes to the top, but what remains is that pure molten iron. That is industrial engineering.

I did not work at Toyota, but I was an industrial engineer. So what choice did I have to develop this thing called job shop lean for John, who was like, “Hey, you've got to benefit heat treaters who have pre-machining and post-machining.” All I had was my industrial engineering, and then I remastered it. I started asking myself if this academic theory is good. What is the practical version? So I looked to the Toyota production system industrial engineering, and I distilled that down and I connected it to all. So all this is metal standard stuff I was taught and read doesn't fit. So I did a Frankenstein kind of thing. I took what worked, and I took the science of industrial engineering and blended it together. And that is what I teach and practice today. It's industrial engineering done my way. It works, I fail, I succeed, learn from my mistakes.

DG: I mentioned to you earlier that our primary audience are manufacturing companies who have their own in-house heat treat departments, so they're somewhat in-line perhaps. But I don't know that many of the industrial manufacturing companies that we deal with really think of lean being an element of their heat treat operations. So, my question to you is could you come up with, on the spur of the moment, say, 3 to 5 of the most common opportunities that are missed by these manufacturers with their own in-house heat treat departments, if they're not thinking lean and flexible? What are some of the opportunities that they're missing?

SI: I'll give it a stab. First thing is you look at the total flow. Look at sawing, turning, milling, grinding, drilling, heat treating, force grind machining, assembly. You look at heat treating as a process, as a department. Just as you would organize any facility, you ask, ,"Can you identify your value streams?" And heat treatment just becomes a department, a step, in those value streams. All you care about is I get bar stock and I get forging and I machine it through and I heat treat it, improve its properties, force heat treat machining, assembly, and ship. That's the first thing that I don't know, and please correct me, I don't know that these manufacturers who have heat treating simply as a process inside their four walls, but that's the first thing that they've done. Have they designed flexible line, flexible cells? Heat treatment is kind of un-lean. It's process driven. It's very incompatible with, say, grinding or CNC machining, and it's batch intensive. The control aspects of heat treating process, spherodizing and annealing and stress relieving are a lot more involved. But that's important. The first thing is, have we identified our value streams?

The second thing is do we schedule? How do we schedule the shop? There are challenges, but it's not that the challenges are insurmountable. I find that scheduling is the second massive weakness in just about any manufacturer, whether or not they're or aerospace or mining. Whether or not they have heat treat inside or heat treat outsourced, that is the second thing. Scheduling is a big weakness.

The third thing is that heat treatment definitely has process control software that's monitoring the recipes and the heat treat cycles of the furnaces and other processes. Great; but what's missing is the third thing, and that's communication. Multiple manufacturers have heat treatment right smack in the middle of their facility and their pre-heat treat and post-heat treat process steps. I don't believe that they have utilized their control systems more as a communication system to pre-heat treat work centers and post-heat treat work centers. They could be using the software as machine monitoring systems, but they can also use that as manufacturing execution systems. I think that's the third weakness. They have not really connected the heat treat to "Hey, I need to go buy money. And every time product builds up in a batch, I'm losing money." That's the cost of inventory. That's my third observation. They treat this incompatible area, heat treat or furnaces, and we feed them as their own little baby; but they forget the fact that there are pre- and post- links.

One last thing I did some reading about the equipment that you have for heat treatment. I'm not sure, but when I looked at these furnaces, they are all big, long boxes. I don't know that that's the best design of the equipment in that particular industry. In lean, in assembly, they are driven by one-piece flow. They are driven by one person attending multiple stages. They are driven by visual management. And I didn't get the feeling that the big, long boxes that they built were designed for one-piece flow but that they were designed for transfer batch flow, which is what the other sectors of industry are doing. Why should all the parts be on the bottom on the conveyor? Could they be bucket spiral conveyors? Could you use the vertical rather than the horizontal? I think that machine design could learn. And especially if you've got heat treatment inside a bigger facility, you've got to be a lot more creative about how to get one-piece flow, visual monitoring, communication to other departments. I feel that may be a lost opportunity.

DG: The design of the equipment is an interesting aspect to discuss. A lot of times the reason those furnaces, (you're talking continuous furnaces in this case, or semi-continuous furnaces), are long, straight lines with an entrance on one end and an exit on the other, it is a design issue. It is an expense issue. Certainly, there are furnaces out there that can do a U-shape or a serpentine shape, or things of that sort, or even use vertical.

The issue tends to be in a lot of this, the material transfer becomes quite a bit more expensive and a potential maintenance issue, which nobody wants, when we have to transfer baskets or parts on a belt. Transfer systems work well at ambient temperatures; but when you get them up in the high temperatures, you've got a problem. But your point is well taken. I think that the point is, let's take a look at not only the layout of the facility and how we're using it, but the design of the equipment itself could certainly benefit by that.

That brings me to a question here. You and I talked to John Tirpak a little bit and threw this question out, and I thought it was kind of interesting. He said recognizing heat treatment is often characterized with fixed, monumental pieces of equipment. What can be done on either side of the heating and cooling operations to lean out the process? I think his point is well taken. Most people think this is a huge piece of equipment. We can't really lean out this piece of equipment. Maybe that's true; maybe it's not. But I would like to ask you, can we lean out a large static piece of equipment, let say, and if not, are we just talking about leaning out the processes before it and after it?

SI: I cut my teeth with the so-called job shop lean for high mix/low volume in forge shops. So I didn't have the benefit of going into some little family line area and doing one piece flow for textile products or table assembly. It was forges. So what happens with forges is you've got saws and then you've got pre-heat treat furnaces and then you have the big presses and hammers. They are monumental from the get-go. Then once the part gets hammered, it then drops into a wire mesh container, and then some time later the forklift guy comes and drags it off and goes and dumps it some place in the yard. Of course you look at things like right sizing.

A wonderful example that came out of the Toyota world was Ford had built this massive 10 million dollar washing machine that was supposed to be capable of washing many different types of parts, but its up-time was maybe 60%. Toyota went to the local Lowes and bought dishwashers, and they changed the inside of the dishwashers and sized the machine to the volume and the shape of the parts. They "right-sized." They took something that everybody thought was "Oh, that's a monument," and made it flexible, and anything flexible is unreliable. Anything flexible is hard to learn to use. I think that's the whole idea. You have to look at these monuments and say, "What can we do pre-?"

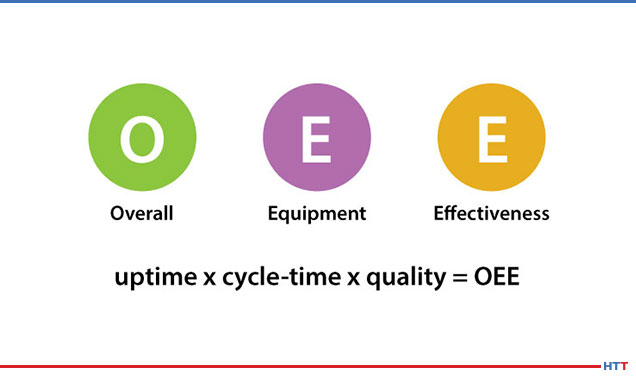

I know that the furnace has to do batches. But how much time that the furnace is just burning oil and electricity and doesn't have a load inside of it? If you ask what is the total time that I've got metal inside the furnace, that is the true value added utilization of that big, hot, long box. Like welding. I don't care about how wonderful a welding station is. I'm asking, what's the arc time? And also, within that arc time, how many of the parts have produced with good welds? That's all I care about. So I think that's what people have to look at, especially those who have heat treatment inside the four walls. They have to use what is called theory of constraint.

They might say we've got heat treat as the constraint. How do we optimize throughput? Then we have pre-heat treat work. How do I flow work so that I'm putting the right orders in the right quantity in the right sequence, always available to go and do that big, long box? And then post constraint; how do I flow product after the heat treat process? People have to use things like theory of constraints and continuous flow, but then they have to adapt the concept. Personally, I believe that the monument thing, once people like you are brought to think about the process, how to break down the constraints of batch, the time that it takes to get that heat cycle stabilized from the previous cycle, I think the creativity has to be unleashed. You recognize the limitations; but if you look at things like right-sizing, downsizing, pool scheduling, buffer management, overall shop scheduling, water spiders who know exactly when they must bring a load to the furnace, water spiders who know when they should take a load from the furnace to the grinding work centers. I think that communication and continuous flow capability, that is how you de-monument the monument.

DG: Your company name is Lean & Flexible, but it seems to me that one of the products, if you will, that you're offering is something called job shop lean. Can you explain what it is and what is the value of it?

SI: So John [Tirpak] came around and said look, I love your research, but I don't want this lean stuff that everybody and their dog is doing. There was MIT and there was Michigan and everybody was having their own program, lean this and lean that. Fundamentally, what they were doing was driven by going and copycating what Toyota was doing. But the fundamental observation that I had was there are essentially two types of manufacturers, at least. There are the OEMs, the John Deeres, the Toyotas, the Boeings. They assemble stuff. You can't take a jet assembly line and make dishwashers on it, right? Then on the other hand, you have these job shops with, what I would say Mom and Pop, but they want to be flexible. They cannot make money by making the same thing, 120,00 pieces of it in the year. They basically are in small volumes, lots of part numbers and different requirements, mature properties, a lot of customers. That creates a lot of uncertainty, that work environment. But whereas the Toyota side is "we will of course use the same assembly line, we might make vans, we might make cars, but we're going to push out just these 4-wheel things. Job shop lean was born.

I stepped back and I said everybody's talking lean, but all this lean stuff is just for assembly. Half the tools don't even work in high mix/low volume environments. So that's when the buzz word "job shop lean" came about. I look at those manufacturers where they've got issues of shifting bottlenecks, they've got issues of suppliers jerking them around, they have lots of changeovers in their set-ups, all their parts go different routes around the shop – that's basically what we call a job shop. But John says, you need to tell me what you're going to do at these fourteen companies that I'm going to set you up with. I had to come up with a plan that I'm going teach my students, thus and such, then we're going to place them at these Ford shops, I'm going to mentor them remotely from Columbus, Ohio, but they'll be so knowledgeable and they themselves are so good, they'll be able to implement this, this, this at your fourteen plants.

And those tools, what works and what doesn't work, that's true. You can't have one-piece fluid heat treatment. You can't do tatk time. A CNC lathe works at a totally different speed compared to a furnace. A CNC lathe can make a piece and pass it on. In heat treatment, you cannot. You have to have a certain amount of mass inside at all times. You can change over a CNC mill within 30 minutes. Try doing that on a furnace with its own recipe from one drum to another. That's what job shop lean is basically saying. We're not going to learn from Toyota what 90% of US manufacturers need to because they're all high mix/low volume. Please listen to me, I've got some knowledge. Toyota was an inspiration, but at a certain point, because they are not telling me the answers to high mix/low volume situations, I'm going to find them myself.

DG: There are a number of companies and people that are going to be listening to this that might ask the question, "How do I know if my company or my in-house heat treat department is a candidate for some sort of lean analysis? Would we benefit by having some sort of lean analysis?" What would you encourage those people inside? What are the signs that they should be looking for in their company that says they should seriously consider some sort of lean philosophy or lean analysis of some sort? What would be the red flags, let's say?

SI: I have a job shop lean assessment tool. It's a 5-page, yes/no type of questioning. If anyone is interested, all they have to do is send me an email and they'll receive that Word document. Put an X to answer all the questions and send it back to me, and I should be able to give them very quickly just walking down their replies, it should be very easy to figure out if yes, you are eligible for this high mix/low volume lean approach because you've got heat treatment and a lot of pre-heat and post heat treat process. That's one step.

The second step would be to get your camera out and take a walk through the facility. In your mind, you have a generic part that you make and you're basically imagining yourself to be that part. You put the camera on your helmet and then you start to walk and talk me through the process. The second thing would be to send me a video. And then we do a Zoom session and walk me through that video.

DG: So, it's more or less a virtual video tour of a typical part and how it's processed.

SI: Yes. I have right now in the age of COVID-19, where instead of worrying about doing business, it's an open offer that I phone the study group for job shop lean, and the only expectation is that I will do as much as I can to work with you via remote with no strings attached; but if you want to get the job shop lean, then you should do a pilot project and you should follow the method.

I'm recording all of my lectures and posting them online on Vimeo so that anyone can access it, no strings attached, no financial expectation. But the third thing is, do something. Do a pilot project. Do what we did at Sysco Forge Group 20 years ago. Do what we did at Aluminum Precision Products. Unless you do it, you're not going to get a sense of "Wow, I didn't even know that we've got 20 types of cutting tool inserts," you know?

DG: Yes. I think with lean, it's not a topic that is often discussed in the heat treat world, and I think the issue here is that there is a lot that people don't know that they don't know. So it's really a discovery process and to that extent, I would encourage people to reach out to you to at least start that discovery process.

Let's talk quickly as we wrap up here, let's talk about some contact information, so people can get in touch with you. What is the web address to at least go there and start looking a little bit more at what you're doing?

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.

Heat Treat Radio #30: Dr. Shahrukh Irani on Job Shop Lean Read More »