In this episode of Heat Treat Radio, host Doug Glenn invites Dennis Beauchesne of ECM USA to explore the technology, benefits, scalability, and sustainability of modular heat treating systems. Together, they discuss how shared utilities, automated transfers, and adaptable heating cells can replace multiple standalone furnaces without compromising quality or precision. Learn how these systems streamline and simplify operations for future expansion — one cell at a time.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

The following transcript has been edited for your reading enjoyment.

Introduction

Doug Glenn: I am very privileged to have with me today, Dennis Beauchesne from ECM USA. We’re going to be talking about modular heat treating systems, which is a growing category of equipment.

ECM Synergy Center (00:50)

Doug Glenn: Tell me about ECM’s Synergy Center, which is where you are at right now, on the shop floor.

Dennis Beauchesne: I’m standing here in the middle of our Synergy Center. It’s about a 5,000-square-foot facility that is dedicated to proving out client parts for testing various processes, mostly LPC, but we also do a number of other processes here. We have a full metallurgical lab, 3D microscope, a number of tools, including a CMM that we can do before and after heat treat distortion testing for clients that want to know how much their parts move.

It’s a dedicated center just for clients to use. We also use the center for pre-completion of installations, final testing, and training, such as training on maintenance, understanding the software, and how everything works together.

Doug Glenn: It’s proof of process plus much more — helping clients’ proof of process.

Dennis Beauchesne: Absolutely. That’s a big part of convincing people that this process is for them and that it works on their part. We can send them ten different reports of an exact same material and part, but they want to know what their part will do.

What is Modular Heat Treating? (02:50)

Doug Glenn: On a very basic, rudimentary level, what is modular heat treating and how does it differ from what might be considered standard or normal heat treating?

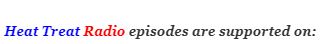

Dennis Beauchesne: A modular heat treat system is one that works together to have more than one furnace working in the same platform. You may have a shop that has five or six vacuum furnaces separated — they each have their own door, vacuum system, electrical supply, quench motors…those types of components. Or you may have a series of batch IQ furnaces for carburizing; those systems are one off, which means they are individual, independent systems.

In a modular system, you try to utilize those facilities for the use of multiple heating chambers. Instead of having one vacuum furnace with one set of pumps and one gas quench motor, what we would do is have three to eight heating cells that would be utilizing one quench, depending on the process timing; that’s all done with an internal transfer car and we try to utilize one vacuum system. It’s much smaller than what you would have for three, four, or even eight cells.

If you had oil or high pressure gas quenching, which is what’s dominating right now in the modular heat treat business, you could supply basically six batch IQ hot zones to one oil quench.

The savings then are huge simply by removing five or six other quench tanks in front of this system, as well as leveraging the floor space (and the number of pits you have to dig). Other advantages including utility savings and utilizing equipment across a number of heating chambers.

Doug Glenn: This modular approach is basically separate chambers that are dedicated to doing whatever that chamber is doing, and they are all in some way interconnected. For standard units, you would heat up, pre-process, do the actual process itself, cool down, all in the same chamber. In a modular unit, you move from chamber to chamber to do each of those separate steps.

Dennis Beauchesne: Yes, I refer to it as a continuous batch.

Doug Glenn: Continuous batch. We were talking before we actually hit the record button with your colleague there, Allison DeAngelo, who just got done visiting the Heat Treat Boot Camp. We were talking about different types of furnaces, and we started talking about continuous vacuum, which of course, is almost a misnomer — a vacuum can’t be continuous because you have to open it up and break the vacuum to get stuff out. Anyhow, we talked about it basically being a batch, right? A batch furnace that’s continuous, a continuous batch furnace.

Benefits of Modular Heat Treating (06:35)

Now that we have a basic understanding of what these modular systems are, why would companies want to move from the standard type of heat treating system to a modular system?

Dennis Beauchesne: Manpower. If you are running five or six vacuum furnaces, you are going to need a number of people to open the doors, put new loads in, those kinds of tasks. With a modular system, you only have one entry or one exit area. Therefore, you are only going to load once every 15-20 minutes, and the system is going to take over and control that load going through the system.

In addition, especially in a carburizing atmosphere situation, you can have every load be a different case depth — a different process in each cell — and then the next load that goes in that same cell can be totally different from the one before. For instance, if you had a batch IQ, you typically use the same carbon potential, and you are typically going to run the next load almost identical to the one before. In contrast, with the modular system, each cell can run a different process every load.

It’s also easier to integrate automation if you are doing capacity increases.

Throughput Comparison (08:00)

Doug Glenn: What is the comparison of throughput between a standard unit and a modular unit?

Dennis Beauchesne: The throughput comparison is interesting because you typically can use a little higher temperature for a carburizing and a little higher carbon potential, and of course that’s what we specialize in here with the modular systems. You can achieve about a 30-40% gain in your cycle time. That furnace is operating very close to 100% occupancy, because when that load is done, you are moving it out right into the gas quench. Then, the next load comes and goes right into it.

Doug Glenn: You are able to increase your throughput because you have basically 100% utilization of the equipment or very close to that. Comparatively, you don’t necessarily have that in the standard equipment.

Product Quality Comparison (09:15)

Doug Glenn: Do modular systems produce higher quality products?

Dennis Beauchesne: The quality of the parts coming out of the system is improved. A vacuum environment is a very clean environment, especially if we are considering atmosphere and low pressure carburizing — it’s in a vacuum. We typically do everything in high pressure gas quenching. However, even in oil quenching under vacuum, you are going to have a much cleaner part.

Also in low pressure carburizing, the carburizing is much more uniform throughout the part because we heat it to temperature under nitrogen before the part gets to austenitizing temperature to start attracting carbon. We make sure that the full part, that’s the tooth, the root, every piece of the part, is at temperature before we start adding carbon to the load, which makes a more uniform case depth, and therefore makes a stronger part.

Doug Glenn: Since each module, each chamber, is dedicated to doing what it is supposed to do, it seems like the consistency and the reliability of the parts being processed in a modular system have a much better chance of being higher quality.

Dennis Beauchesne: You do not have six different variable chambers or six different variable systems. You just have to look at monitoring the connection between those and understanding that the vacuum levels are all the same across the levels and across the cells. Each cell can meet a different temperature and run a different process, but those are consistent across the board.

Typical Dedicated Cells/Chambers (11:10)

Doug Glenn: What would be the typical dedicated cells/chambers of a modular system?

Dennis Beauchesne: It is dependent on the processes. They are most widely used for vacuum carburizing. For pre-oxidation and preheating, we usually use an air oven outside of the system, and we connect that with an external loader. Before the load goes into the modular system, the load will go through a regular air oven, be heated to around 700°F (400°C), and then the load will be moved in.

For sintering and those kinds of applications, there is a debind step or a preheat step that would be done in one cell. Some of the processes that can be done in a modular system include:

- Low pressure carburizing

- Low pressure carbon nitriding (LPC)

- FNC (ferritic nitrocarburizing)

- Nitriding

- Debinding

- Sintering

- Neutral hardening

The most prominent process right now is LPC, and that is being used all over the world in these systems.

Advantages of a Modular Unit for Captive Heat Treaters (12:53)

Doug Glenn: Why would a modular unit be beneficial for a captive heat treater, someone who does their own in-house heat treating, which probably means they’ve got potentially high volume, low variability as far as their workloads?

Dennis Beauchesne: The modular unit has many different advantages. First of all, floor space. You are going to save a lot of floor space by not having multiple furnaces set up separately. You will also save utilities because you would not have as many vacuum pumps or electrical systems running these furnaces on their own. You will have some shared service and utilities in that fashion.

Doug Glenn: That would also likely lead to maintenance cost savings as well, correct?

Dennis Beauchesne: Yes, it all goes down the line. Anything that you have multiples of, you are going to have much less costs than on a joint system. The modular system might be a little larger than one singular unit, but there will be fewer of them.

For vacuum carburizing applications in a captive shop, the quality and cleanliness of the part is very, very important. Gas quenching lends itself to no oil in your plant, no washers necessary for a post-quench. Typically, there’s a washer before the process starts, but you do not have to have any wash to get the oil off of the parts with a modular unit — you do not have to reclaim the oil or the water from the washer. You would not have waste oil in your plant either or any oil on your plant floor. These are some of the reasons some of the larger captive shops have gone to the modular systems.

Also, safety: There are no open flames with a modular unit, no risks of fire on the systems. They are also easier to maintain. For a fully operational, let’s say, eight-cell system for high production, captive operation, it would only take about five hours to cool that whole system down if you had to go in and work on the whole system. In comparison, it’s going to take you three to four days sometimes to cool down a typical atmosphere, high-temperature furnace.

It also takes time to heat the system up again. In a modular system, it takes about an hour and a half to heat the system up again and then you are ready to start running. That means now you can schedule your downtime on weekends or holidays. You do not have to have staff present to run anything.

You also do not have to have a secondary equipment, like Endo generators running to feed the carburizing gas. The carburizing gas is using acetylene out of cylinders, it’s not a regenerative system. You do not need a separate piece of equipment to feed to the furnace.

Another benefit is CapEx expansion. Typically, captive heat treaters do not want to buy everything upfront because their volumes are going to increase over time. In the beginning, they typically only need one or two cells ready to do a small amount of production so they can prove out the production and prove out the system. Then they can start building the system with more cells and more capacity later on. Generally, it’s two to three days of downtime to add a cell to a system. It’s very convenient to do that with a modular system. All of the utilities are typically alongside the modular system so that you can easily add those or add a cell to it over a short period of time, and those cells can be ordered a year or two down the road whenever you might need that.

You also can order peripheral equipment, like extra temper ovens or additional automation. You can add a robotics system to the layout as well. That’s why captive shops are very interested.

Finally, workforce: It’s a little bit easier to get someone to work on a modular system. These systems are completely clean and white. The one located in our Synergy Center has been there for eight years. We use it every single day, and it’s a very clean aesthetic environment for someone to work in. These systems are also water cooled, which means not a lot of extra heat in the building around you to work in.

Advantages of a Modular Unit for Commercial Heat Treaters (17:59)

Doug Glenn: What are some advantages of modular units for commercial heat treating?

Dennis Beauchesne: On the commercial heat treat side, modular units are typically useful because you can get multiple processes out of similar cells and you can have a system that has oil and a gas quench.

You can have a lot of flexibility in that one system that you have in the plant. I’ve visited hundreds of captive and commercial heat treaters. They generally have a number of furnaces in one area of the plant, and a number of furnaces in another area of the plant. A modular system gives you all the capability in one machine and one tool: oil quenching, gas quenching, FNC, nitriding low pressure, carburizing, carbonitriding, and neutral hardening all in one piece of equipment.

Automation and Robotics with Modular Heat Treating (18:57)

Doug Glenn: What automation and robotics advantages are there with modular systems?

Dennis Beauchesne: This is the new trend. People that have modular systems are now considering, “How do I automate the system to get more production out of it?” And what we’ve been doing the last five years especially is implementing systems that use CFC fixtures.

CFC fixtures are very robust in the furnace but sensitive to being controlled outside. Therefore, what we try to do is have the CFC fixtures be utilized in an automation that no humans have to interact with it. We usually use robots for external loaders and internal loaders to move the fixtures through the process.

This causes you to have a lighter load, which means less heating time, less energy being consumed. Also, the fixtures last three to four times longer if they’re not damaged. But of course, all of these systems can be using regular alloy steel as well, and we can fixture different parts. You can use baskets, we are now doing bulk loading where we have parts that are filled into baskets and then processed. We are doing that with vacuum carbonizing as well, not just neutral hardening.

So it’s really interesting to see how the limits are being pushed, as well as the different materials that we are gas quenching now. I know 20-25 years ago, we were quenching some simple materials that were very high hardenability, and today we’re quenching a lot of less hardenability steels.

Doug Glenn: Is that primarily due to increase of pressure in the quench?

Dennis Beauchesne: It’s pressure, it’s flow, it’s the intensity of the gas going through the parts. It’s also heat removal as well — heat exchangers, removing the heat out of the load faster. We also have reversing gas quench motors to reverse the flow inside from top to bottom, bottom to top, in the middle of the cycle.

Sustainability of Modular Heat Treating (22:24)

Doug Glenn: Do these systems promote sustainability and greenness?

Dennis Beauchesne: Absolutely, especially when it comes to carburizing. These systems have been compared against typical atmosphere carburizing cycles, and only about 4% of the carburizing time has gas injection, when we are actually injecting acetylene and having hydrocarbons being used in the process.

If you took the same cycle times, seven or eight hours of a carburizing cycle, you are flowing Endo gas or nitrogen methanol in the system for that full time. In contrast in a vacuum carburizing system, it’s 4-5% of the time of the cycle that you’re injecting into the furnace. Ultimately, you only have about 10% of the CO2 output that you would have in a typical atmosphere furnace.

As mentioned previously, there’s also no oil in your plant. You’re not reclaiming oil out of the water and the wash or off the floor or in your car when you leave your heat treat shop.

How Does the Modular Heat Treating System Work? (23:40)

Doug Glenn: Let’s talk through the process a little bit. You provided us with figures to aid in describing the process. We have included these. Describe how the system works.

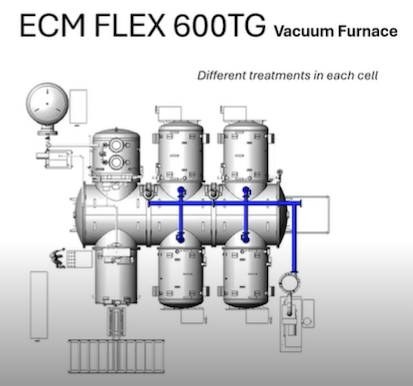

Dennis Beauchesne: This animation is a plan view of one of our Flex systems. In the center, going left to right, is a tunnel section. This tunnel section is about an 8-foot diameter. It has an automated loader that moves down left to right or horizontally, and it transfers loads from each cell to another, in and out.

On the bottom left is a loading/unloading chamber. In that loading/unloading chamber, we remove the air once the load is put in there, and then we balance the vacuum on that cell to the tunnel’s vacuum. Then we’re capable of moving that load to an available heating cell, and that would be on the right of the system — on the top right or the bottom right of the tunnel, those are heating cells. Then recipe for that particular load will be loaded into that cell. While that load is processing, another load will be moving into the tunnel and into the other heating cell as well.

On the top left is the gas quench cell, which could be in this orientation or instead have an exit on the back as well. In this system, you could do neutral hardening, carbon nitriding, LPC, a number of the processes. This is a very valuable tool, especially in a commercial heat treat heat treat shop.

Doug Glenn: Is this whole unit, including all four chambers under vacuum? I noted there are separation doors on the purge and the entry chamber. Can this area be vacuum sealed?

Dennis Beauchesne: Yes. There are vacuum seals on the loading/unloading chamber on the bottom left and then the top left. The gas quench also has a seal from a pressure standpoint. The two heating chambers have a graphite door — we call it the flap door, and it just flaps and it doesn’t really seal actually against another face of graphite. It’s graphite-to-graphite. We pull vacuum out of there through the tunnel to create the central vacuum pressure in the system. We also pull vacuum from the cell itself, and we could also have a separate door on the front of the unit if the process necessitates that or if we feel that a door is needed there by a client.

In a normal state or a standard unit, there are no hot seals on the door, only vacuum seals on the loading/unloading chamber and the gas quench.

Doug Glenn: In the animation, your vacuum pumps are down in the bottom right, correct?

Dennis Beauchesne: Exactly, that’s a process pump.

Doug Glenn: What is located in the top left?

Dennis Beauchesne: On the top left, we have a gas quench tank. We want to ensure we have enough gas pressure and volume there to quench the load quickly. It’s very important to get the gas through the gas quench quickly.

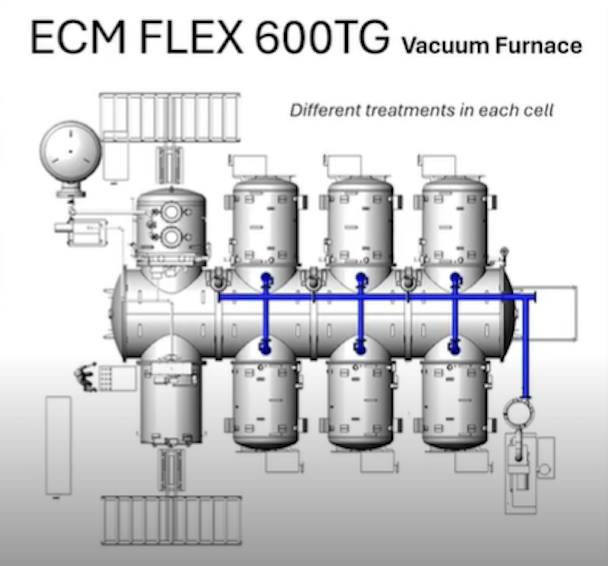

Now, we have added two more additional heating cells and a central tunnel section. In essence, you just doubled the space, doubled the capacity of the unit, where you only added 50% of the space of what you had for capacity before.

We are still utilizing the same gas quench and the same loading/unloading cell. We only added utilities for the two heating cells, not for a whole gas quench or oil quench capability there; this can be added in a very short time.

Doug Glenn: Now I’m gonna go let this video roll here for a minute. There we go.

Dennis Beauchesne: So now we added another 50% capacity with two more heating cells (six heating cells total) and a tunnel section. Typically, what you want to do is to have the tunnel sized for about five years out for your capacity and then buy the cells as you need them and have it grow so then the tunnel is ready to implement.

We have just tripled the capacity of this installation, and we are only still using the same gas quench and the same loading/unloading cell. Generally, this system could go to eight cells and have just one gas quench, that’s our typical orientation.

Doug Glenn: It looks like we also added a discharge side here. Whereas before we were going in and out.

Dennis Beauchesne: Yes, this adds to the efficiency of the system because the load is already in the gas quench when it’s finishing, so it just exits out the back, out the door.

Doug Glenn: Now what do we have here?

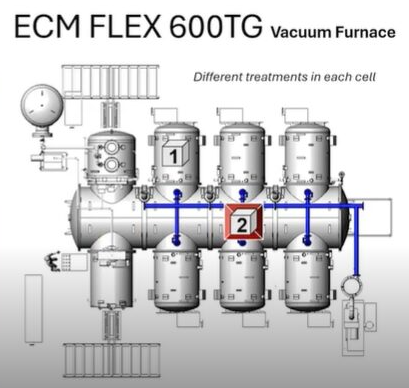

Dennis Beauchesne: We have the loads entering, and the loads will go to the first cell that is available (empty). Then that recipe would be downloaded for that cell, and then the next load will go to the next available heating cell and download that recipe into that cell. These could be two different loads.

One load could be for neutral hardening; one could be for carburizing. One could be for carburizing in a low case depth. The other one could be carburizing at a deeper case. In this case, we just see the gas quench on here, but this tunnel could also be outfitted with an oil quench as well, and you could have one load go into gas, quench one load, go into oil quench or both going to either.

Doug Glenn: This gives people a sense of what the process looks like.

Processes and Materials for the Modular System (30:29)

Doug Glenn: Are there any processes or materials that do not make sense to process them through one of these systems?

Dennis Beauchesne: If you are doing a lot of annealing and normalizing, those are longer cycles. There is some regulated cooling that occurs. This is not really the type of equipment investment that you would want to make for those processes. If you were going to use it for a few loads in your plant where you received parts that weren’t annealed or you wanted to try to anneal a part for a particular process before you went to full production, you could certainly use a modular system for that, but it’s not a cost effective methodology. Neither would we recommend preheating in the cell. However, it is very flexible for a number of other processes that we have mentioned.

The size of the part is also important to note. These systems are typically 24 inches wide and about 39 inches long and about 28 inches high. However, we will soon have a new system, the Flex Max, a 12-9-9 system. It’s a 36×48 unit that comes with an oil quench and is modular, like this. We can either do an oil quench or a slow cool cell on that system. So, we will have that capability of 36×48 in that modular system.

Other than that, restrictions on material? Very few there. Like I said, you would not want to do annealing and normalizing on a lot of parts, but you could do it in these units.

Doug Glenn: It sounds like the sweet spot is surface modification type applications, and some sintering is possible with dedicated chambers.

Dennis Beauchesne: Yes, sintering and brazing is also possible.

Doug Glenn: Does that include aluminum brazing?

Dennis Beauchesne: Not aluminum brazing, but some brazing applications.

Expenses with Modular Heat Treating Systems (33:03)

Doug Glenn: What would be considered capital expenses for this modular system?

Dennis Beauchesne: As far as capital expenses, it’s not a furnace-to-furnace comparison. Clients always ask how much our furnace is. But companies need to first take two steps back and take a look at their incoming material, how they would like to be able to modify that incoming material in their heat treat process to make sure that their outgoing quality is higher than it is today. That’s the kind of benefit that this type of modular system gives you — a better quality part, safety in your plant, and a better quality work environment with being able to turn the system off and not need additional personnel around.

These are all factors that have to be considered when thinking about the CapEx expenditure and investment. When we consider these factors, a modular system investment is a much better situation than looking at a furnace-to-furnace replacement, and that’s really the thought process that clients need to go through to understand the actual investment and value of the system.

Doug Glenn: What about the operational expenses?

Dennis Beauchesne: For instances, if you had a batch IQ sitting there, you would typically keep it running whether it has a load in it or not. With a modular system, you just shut off that cell that you’re not using. It does not take any more energy. If you are not working five days a week, you do not use it on the weekends — you shut it off. You do not use it during Christmas shutdown or any holiday shutdown, vacation shutdown. You’re able to shut it off and that means saving a lot of energy and labor by having it off.

Also, in the opposite way, you could run it lights out if you wanted, as well. You could stock up a number of loads on the automation before you leave, have the system operate it, run it, and have the load come back out before the morning. You could have it time start as well, if you wanted to start it on Monday at 5 AM, but you will not be there till 8 AM. You would come in and the furnace would be hot and ready to run a process.

There are a number of operational advances over the typical operational heat treat that’s out there today.

Doug Glenn: How does maintenance work with these systems? Say your heating element goes bad in cell number three, do I have to shut the whole system down to fix or can I fix number three and leave the rest of the system up and running?

Dennis Beauchesne: In this situation if you had a tunnel like we showed, you would typically shut off that cell; that is, if you knew that heating element was out or it wasn’t heating properly, you could shut off that cell, de-validate is what we call it, and then keep running the rest of the system until you had a window in your production that you could shut the whole system to get into that heating element.

If you had a system with doors on the front, it could be possible to go in the back while the system is operating. Then, it would be all based on your safety requirements for your plant and those kinds of things.

To do that, we have another system called the Jumbo, and it is much more flexible in the maintenance world. It has a vacuum car that moves down on rails and docks and mates with every heating cell on the system. In that line, the heating cell can actually be isolated from the rest of the line. You would just slide it back (It’s on wheels, it slides back about three feet away from the line), you put in a new piece of safety fence, and you continue to run your line. You can completely lock out/tag out that cell and work on it completely.

Doug Glenn: How would you approach a vacuum leak since the whole system is connected, right? I believe you mentioned these are graphite-on-graphite doors.

Dennis Beauchesne: You would want to fix the leak before you move on. Especially if it’s a bad leak. If it’s something that’s causing you to not maintain your process pressure, you certainly don’t want to do that, and that’s true with every vacuum piece of equipment.

ECM Modular Systems (38:55)

Doug Glenn: How many of these modular type systems does ECM have out in the marketplace?

Dennis Beauchesne: The Flex is the most popular modular system, which we discussed with the animation. We also have a number of Jumbos systems, and the unit in our Synergy Center is called a Nano, which has become more and more popular these days. The Nano has three different size chambers, but they’re typically smaller, 20x24x10 inch high size chamber. I explained a little bit about the Flex and the Jumbo is the same.

Out of those three systems, we have more than 350 modular systems, not just the heating cells, but more than 350 systems that are out in the marketplace today operating, running parts every day, running millions and millions of parts every week. Those systems are comprised of about 2,000 heating cells. As much as people hear about this being a new technology, it has actually been around about 30 years, and many companies have been using these systems and have replaced a number of pusher furnaces and those style furnaces for high-capacity installations especially.

Doug Glenn: Okay, that sounds good. I really appreciate your time.

About the Guest

General Manager

ECM USA

Dennis Beauchesne joined ECM over 25 years ago and has since amassed extensive vacuum furnace technology experience with over 200 vacuum carburizing cells installed on high pressure gas quenching and oil quenching installations. Within the last 10 years, his expertise has expanded to include robotics and advanced automation with the heat treat industry high-demand for complete furnace system solutions. As General Manager of ECM USA, Dennis oversees customer supply, operations and metallurgical support for Canada, U.S., and Mexico for ECM Technologies. He has worked in the thermal transfer equipment supply industry for over 30 years.

For more information: Contact Dennis at DennisBeauchesne@ECM-USA.com.