![]()

Induction heat treating: no harsh chemicals, gases, or even CO2 emissions. But to get there, heat treaters should first understand how to plan for an induction design and fabrication project upfront. Consider these five important factors before you dive into induction.

This Technical Tuesday article was composed by John Chesna, general manager at Induction Tooling, Inc. and honoree in Heat Treat Today's 40 Under 40Class of 2022. It appears in Heat Treat Today's May 2023 Sustainable Heat Treat Technologies print edition.

Introduction

General Manager at Induction Tooling

Source: Induction Tooling, Inc.

There are many less than obvious factors to consider when preparing and planning for induction. So where to start? There are five important factors that manufacturers with in-house heat treat operations should understand in order to successfully prepare an induction heating project and design.

But first, what is induction heating? Induction heat treating is the process in which a high frequency conductor (induction tool) induces currents (eddy currents) into an electrically conductive workpiece. Without ever touching the work-piece, the current generated and the resistance causes heating. Ever since its proven usefulness around the time of World War II, induction has been chosen as the go-to heat treatment for a variety of applications across many industries including agricultural, medical, and transportation. Now, it seems that most industries have taken advantage of induction heat treating, and its popularity will likely only continue to increase with the push for the use of “clean” and “green” energy.

#1 Plan for Inductor Wear

One of the most important factors to an induction project is realizing the inductor/ coil is a wear item. It can be highly engineered, hand fabricated, machined, or even 3D printed. Yet, in the overall process, it is still a wear item: an item that will eventually require replacement or repair. The inductor is exposed to the worst of the elements during the induction process and can fail from standard use, accidents, or unforeseen circumstances. Inductor designers are constantly being challenged to create tools that will last longer, require less maintenance, or run more cycles. All of those can be achieved, but the inductor will eventually require replacing and that is not a bad thing!

A properly serviced and maintained inductor will ensure quality parts are being produced. As the inductor wears, the efficacy degrades, leading to undesirable results. Repair of the inductor will correct this issue and ensure the parameters required for the desired heat treat pattern are restored. Depending on production needs, a good principle is to have more than one inductor on hand so that while one is being repaired the spare inductor can remain on the machine to keep up with manufacturing demand. Planning for this is important for the project’s timing and budget.

#2 Types of Inductor Designs

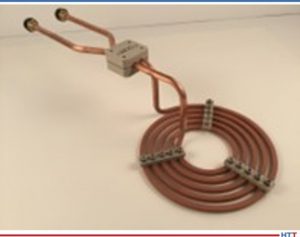

Determining a specific inductor design will be necessary to properly heat parts. The inductor creates the magnetic field in the workpiece, and typically the inductor is shaped to couple closely where heat treatment of the part is desired. Additionally, if quenching is required for the heating application, this function will be considered in the inductor’s design. The inductor’s design must deliver the electrical energy and quench medium to the workpiece while allowing accessibility for material handling purposes. For this reason, inductors take on many different designs.

Photo Source: Induction Tooling, Inc.

Photo Source: Induction Tooling, Inc.

Photo Source: Induction Tooling, Inc.

Common inductor designs include:

- Pancake: used for heating flat surfaces

- Single turn or multi-turn: commonly shown as copper tubing wrapped around cylindrically around the workpiece

- Hairpin: typically, a simple back and forth loop used to heat long lengths internally or externally on the workpiece

- Split return: used to focus the energy in particular areas of the workpiece

- MIQ (machined integral quench) paddle: the most commonly used design for scanning applications

#3 Power and Frequency

Know the power supply and/or work-head power and frequency. Depending on the composition of the part that requires processing, the power and frequency of the equipment will help estimate the depth of the pattern that can be achieved, as well as help determine how successful the part will be for induction heating. Irregularly shaped geometries with points, holes, or sharp edges sometimes cause difficulty establishing eddy currents where the induction pattern is desired. Some parts, after review, are good candidates for induction heat treatment but cannot be processed with the existing power supply and/or work-head setup.

If an inductor is being built to mount to existing induction equipment, it is important to know the scope of parts that are currently being processed or expected to be processed on the machine. The electrical circuit of the power supply, work-head, and inductor must load match to the part. If a variety of parts are being run then multiple styles of inductors may exist or will be required to be used. Different designs of inductors, e.g., single-turn, multi-turn, or split return used on the machine will change the transformer effect and capacitor requirements of the system. Availability to tune the system capacitance and inductance becomes vitally important for operation. Please note that adjusting capacitance can be dangerous and should only be done by a trained technician. Newer power supplies function differently than older models, yet load tuning needs to be considered.

#4 Part Details

A detailed pre-induction print is needed. The print should list the material as well as the desired heat treatment pattern to determine the inductor design. As the print specifies the pattern, it should also provide limits. Inductors are then typically designed to the shape of the part. The inductor may require an integrated quench, electrically insulating protective coating, locators, or additional assembly fixturing depending on the part’s size. An inductor built for one part may be used or tried on a similar part. However, the same results cannot be expected to render on the part for which it was not designed. If the manufacturer knows that a family of parts will be run, the full scope should be presented to inductor designers for consideration before the build.

#5 Material Handler

Ideally an inductor supplier would be contacted to develop the induction heating process for a part; then, that information should be shared with the material handling designer. That would be the ideal, but that’s not the way it usually happens. Sometimes, a machine is built to process a part that no longer is in use, so the machine is now being retrofitted to process different parts. The design of a new inductor is needed to accommodate this existing machine which may create size constraints to the inductor’s design.

The contact style, how the inductor mounts to the work-head, will need to be determined. There are a variety of commonly used power supplies and work-heads available from OEMs in the market. As each OEM keeps their contacts standard to their equipment, there is no singular standard footprint in the market. Once the contact style has been determined, the inductor can be designed for maximum power delivery efficiency. How the part and inductor are presented to each other is important. The centerline distance, a measurement from where the inductor mounts to where the part will be processed, needs to be known. The centerline determines the required length of the inductor and indirectly how much room is available for the inductor’s design.

Conclusion

Due to the variety of factors, no two projects are ever the same. Induction heating is an exciting technology, and I encourage everyone to learn more about it.

About the Author: John Chesna is the general manager of Induction Tooling, Inc. and has been involved with the induction heat treating industry for over 8 years. He is a graduate of the University of Akron with a Bachelor of Science in Mechanical Engineering Technology. His responsibilities include overseeing day-to-day operations including the design, manufacturing, and testing of induction heat treating inductors. Additionally, John was a recipient of Heat Treat Today's 40 Under 40 award in 2022.

Contact John at jchesna@inductiontooling.com.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com