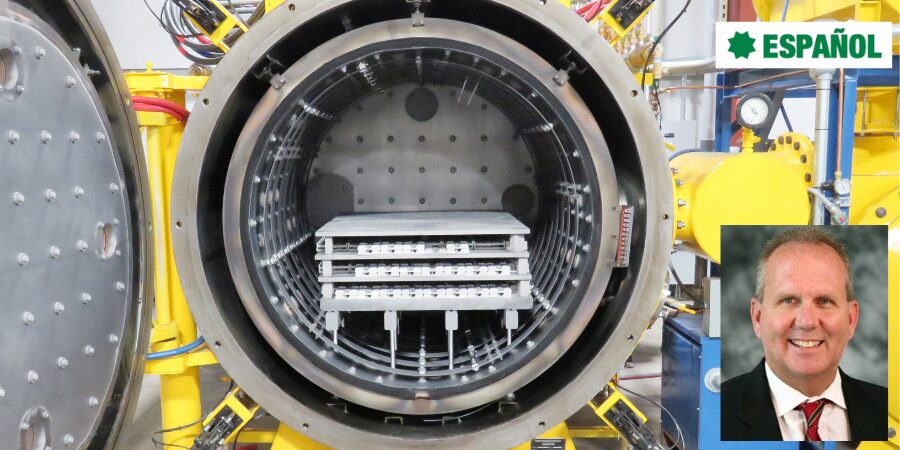

Custom furnace design isn’t just about performance upgrades — it’s about process reliability. Vacuum furnaces built for general use, however, often fall short in high-precision industries. This Technical Tuesday installment comes to us from Scott Herzing, vice president of Engineering at Paulo. Explore how purposeful furnace design, smarter controls, and targeted customization can transform vacuum heat treatment.

This informative piece was first released in Heat Treat Today’s November 2025 Annual Vacuum Heat Treating print edition.

The reliability and consistency of vacuum heat treatment processes depend heavily on furnace design and performance. Standard furnace configurations typically serve general heat treating applications adequately. However, for industries with extremely demanding requirements, such as aerospace, automotive, and power generation, small variations in furnace design can lead to substantial impacts on part quality, increasing risks and costs. Achieving exceptional process control and repeatability often requires custom furnace modifications tailored specifically to the unique requirements of each process.

Extensive customization of vacuum furnaces can initially seem costly and complex. It takes experience operating and refining vacuum furnaces to know which adjustments deliver the greatest impact. This article taps into the more than fifty years of heat treating wisdom from Paulo with six key factors that drive better furnace performance, enhance reliability, reduce downtime, and create measurable efficiency gains.

Why Customization Matters

Conventional vacuum furnace models offered by manufacturers are generally designed to meet broad market demands. This often results in equipment that effectively balances functionality, affordability, and ease of use for a wide range of applications. However, certain high-precision thermal processing applications, especially those involving aerospace components like single-crystal turbine blades demand much stricter temperature uniformity, controlled quenching rates, and near-perfect repeatability from cycle to cycle.

In these cases, standard configurations can introduce variability that compromises quality. A better path is a case-by-case approach, evaluating specific process risks and targets critical components for modification. Precision upgrades can be integrated where they have the greatest impact, achieving the required level of process control. This makes it possible to achieve near-zero scrap rates, dramatically boost reliability, and achieve repeatability that far exceeds industry norms.

Advanced Pressure and Cooling Control

Repeatable quench dynamics is a game-changer when it comes to part quality. Integrating advanced gas control capabilities that extend beyond basic pressure management can help you improve heat treating results. To do this, you need to precisely control the rate at which gas is introduced into the vessel using proportioning valves, not just the pressure setpoint. For controlled cooling cycles, systems also need to manage the fan start speed, allowing you to tailor the convective heat transfer to the geometry and mass of each part. This level of precision ensures consistent metallurgical results and protects part integrity.

Automation-Ready Resilience

In multi-furnace environments that rely on automation and minimal staffing, power-failure restart behavior cannot be left to chance. Adding dedicated PLC logic for restart allows the system to record the exact state at interruption, verify safe conditions on recovery (atmosphere, temperature, motion, interlocks), and automatically sequence a safe restart when criteria are met. This reduces scrap risk, protects equipment, and stabilizes throughput, especially when only a few operators are covering many furnaces.

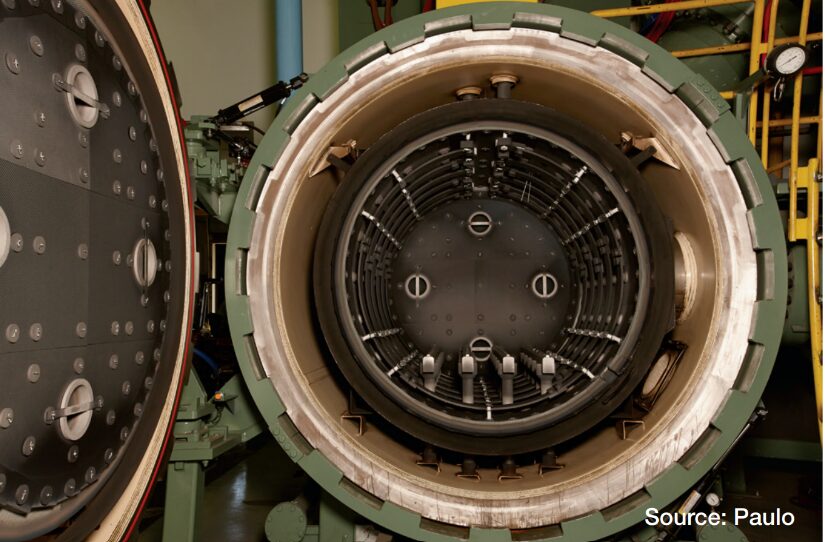

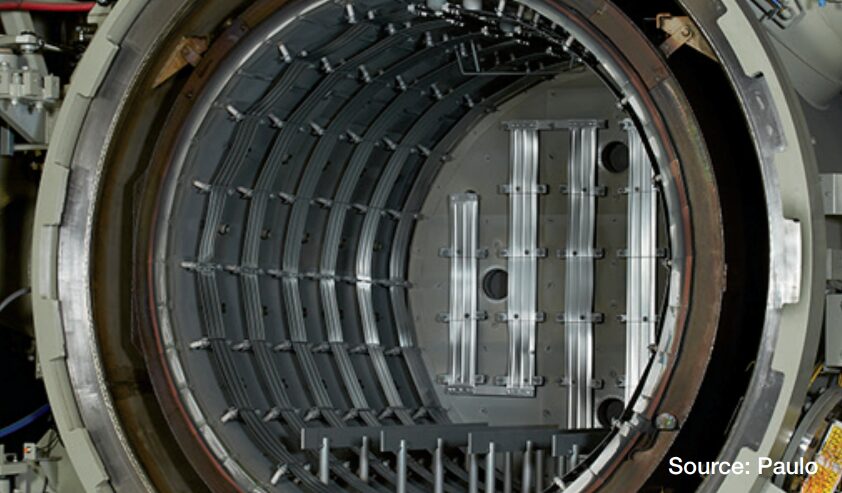

Hot Zone Design and Material Selection

A major component directly influencing furnace reliability and overall performance is the hot zone. As the central area where thermal processing occurs, the hot zone repeatedly experiences extreme temperature fluctuations, making its design crucial to operational efficiency and product quality.

Standard vacuum furnaces use thinner insulation layers and lower-cost materials to control initial investment costs. However, advanced hot zones can dramatically outperform these standards by incorporating thicker insulation layers, strategically placed air gaps, and specialized insulation materials, such as high-quality molybdenum, graphite felt, or carbon-fiber-carbon (CFC) boards.

These advanced materials not only prolong hot zone life but also substantially reduce heat loss, minimizing energy consumption and improving thermal uniformity. The enhanced durability also results in fewer service interruptions, less downtime, and lower long-term maintenance costs, ultimately justifying the higher initial investment. At Paulo, this is how we’re able to reliably run around 29,000 cycles per year in over thirty furnaces at our Cleveland facility.

Additionally, the hot zone’s construction details, including how insulation and heating elements are attached, can significantly affect longevity and reliability. Standard fasteners or attachment mechanisms may perform well in general applications but frequently deteriorate under high-stress thermal cycling. High-performance fasteners specifically engineered for high-temperature stability reduce the risk of premature failure and minimize downtime.

Enhanced Sensor Integration

Furnace reliability and consistency rely heavily on the accuracy, quantity, and strategic placement of sensors within the furnace chamber. Manufacturers’ vacuum furnace designs typically include a limited number of sensors monitoring basic parameters, such as temperature, pressure, and vacuum levels. Increasing the number and distribution of sensors throughout the furnace interior allows for a more detailed and accurate understanding of conditions during processing. By placing multiple sensors at critical points within the hot zone and throughout key furnace components, operators can detect subtle differences in temperature distribution, heat flow, gas pressures, and quench rates that might otherwise go unnoticed. This enhanced sensor density provides the detailed data necessary for real-time process adjustments, early detection of equipment issues, and predictive maintenance interventions, significantly improving process reliability and part consistency.

In addition, the rich data captured by a denser sensor network improves traceability and enables rapid identification of root causes when process deviations occur, ultimately reducing the risk of quality issues and equipment downtime.

Centralizing Your Control System

One often-overlooked factor in achieving highly consistent heat treating results is the adaptability and responsiveness of furnace control systems. Modern furnace control architectures benefit from a centralized SCADA layer with deep PLC integration. By recording every PLC input (thermocouples, switches, interlocks, drives, flows, pressures), the system enables technicians to diagnose issues without walking out to the furnace and manually testing components. With complete signal histories available, furnace issues can often be diagnosed and resolved remotely in minutes, improving first-pass resolution and minimizing production disruption.

Integrated control software should do more than log data; it should actively protect quality:

- Automated compliance control: Continuously track process parameters, alarm on deviations, and initiate quality quarantines when limits are exceeded to prevent suspect parts from re-entering the supply chain.

- Element-health monitoring: Monitor heating-element resistance to detect early signs of a heating system issue. If an anomaly is detected, automatically stop the heating process to protect parts and prevent secondary furnace damage.

These safeguards shift intervention upstream and reduce reliance on manual inspection alone.

Extending Auxiliary Equipment Life with VFDs

Variable-frequency drives (VFDs) on pumping systems can substantially extend motor and bearing life by matching speed to process demand and reducing mechanical stress. When control logic conditions are met, slowing pumps lowers load, heat, and vibration, which are key contributors to premature failures.

- Without VFDs: Bearings on 615 blowers typically require replacement every 1–2 years, and motor failures occur more frequently than acceptable.

- With VFDs + logic-based speed reduction: Bearing-change intervals extend to 10–20 years, with no motor problems, reflecting a step-change in reliability and lifecycle cost.

This targeted upgrade is a practical, high-ROI improvement that also helps decrease unplanned downtime.

Practical Realities and Final Considerations

Extensive furnace customization offers clear advantages, but it is not always practical for every operation or budget. In many cases, targeted, incremental upgrades — such as refining hot-zone insulation and attachment methods, adding or repositioning select sensors, or phasing in improved control software and deeper data storage/analysis — deliver measurable gains in reliability and process quality without large upfront costs.

Another practical path is to partner with a commercial heat treater that has already engineered and validated these enhancements at an industrial scale. This option can accelerate access to higher levels of precision and repeatability without requiring capital investment, engineering bandwidth, and learning curve of doing it all in-house.

Ultimately, achieving reliable and repeatable heat treatment results involves careful consideration of furnace design and functionality, aligned closely with your process requirements and economic realities. While extensively customized furnaces represent the ideal for particularly demanding applications, understanding the targeted areas where smaller customizations can yield significant improvements empowers heat treaters across the industry.

About The Author:

Vice President of Engineering

Paulo

Scott Herzing is vice president of Engineering at Paulo. He leads the company’s metallurgical, project and automation engineering, fabrication, and lean technology groups. With over 27 years at Paulo, Scott applies his passion for leadership, engineering, and problem-solving to help customers achieve advanced heat treating outcomes.

For more information: Contact Scott Herzing at sherzing@paulo.com.