Furnace for Aerospace In-House Heat Treatment

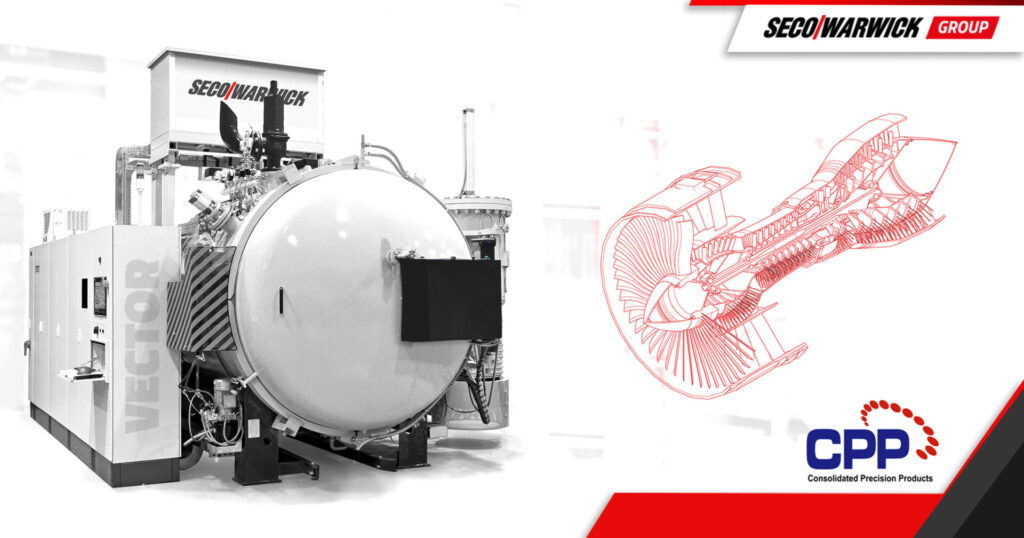

Consolidated Precision Products (CPP) commissioned a vacuum furnace for in-house heat treatment of jet engine blades from single crystals. CPP is an aviation parts manufacturer headquartered in Cleveland, OH, that specializes in highly precise, geometrically complex aviation industry systems and components in the United States, Mexico, and Europe.

Foundry Director of DS/SX

Consolidated Precision Products

Source: Linkedin

“This particular vacuum furnace will be used for the production of a new line of jet engine blades from single crystals. The turbine elements used in the aviation industry operate under high mechanical loads at temperatures close to their melting point and in an aggressive corrosive environment. Therefore, we cannot afford structural defects that would affect the quality or durability of our products. The SECO/WARWICK vacuum furnace will provide us with very high-quality processed elements, but it will also increase efficiency,” explained Dariusz Szawara, foundry director of DS/SX at Consolidated Precision Products.

Sales Engineer

Vacuum Plant SECO/WARWICK

The furnace has a working space of 900x900x1200 mm, screen insulation, and metal heating elements.

“The round heating chamber allows for the placement of oversized elements. The furnace has been expanded and modified with dedicated options to meet very high requirements: high vacuum, temperature distribution, operation at high temperatures around 1300 degrees, and cleanliness of processes. The device will be used for annealing blades cast from single crystals. Its advantage is the molybdenum heating chamber, which prevents direct heat loss to the wall of the vacuum chamber and ensures very high process cleanliness. The efficiency of the processes carried out is also influenced by the ability to cool in 1.5 bars of Argon,” said Paweł Okińczyc, sales engineer at the Vacuum Plant of SECO/WARWICK.

Press release is available in its original form here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Furnace for Aerospace In-House Heat Treatment Read More »