Heat Treat Supplier Receives Patent for Vacuum Furnace Control Thermocouple

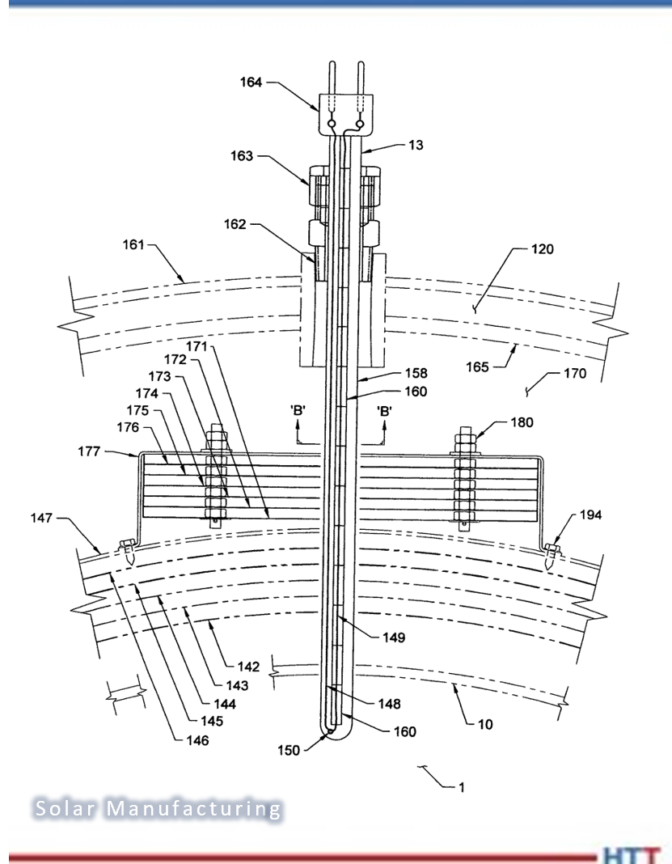

Solar Manufacturing has received a patent for an improved vacuum furnace control thermocouple design. The new thermocouple design offers an advantage when controlling at operating temperatures from ambient up to 1200°F (649°C) especially in smaller diameter hot zones of 36” (91.44 cm) or less.

The new thermocouple configuration was developed to lessen the undesirable thermal conduction losses of the thermocouple assembly. This thermocouple design has also demonstrated to improve temperature uniformity survey results. To satisfy AMS 2750 standard temperature uniformity specifications, it is critical to have the control thermocouples in the proper location of the hot zone for satisfactory survey thermocouple measurements without correction factors.

The patent inventor is William R. Jones, owner of Solar Manufacturing, Inc.

Under these conditions, the outer ceramic protection tube of the conventional control thermocouple design acts as a heat sink. This thermal conduction, or the heat loss, is compounded by the shorter length of the thermocouple assembly and causes the control thermocouple to operate at a lower temperature, thus increasing the power output to the furnace heating elements to maintain set-point temperature. The result is the workload temperature hotter than the furnace temperature. The phenomenon is more pronounced at lower processing temperatures (<1200°F/649°C).

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Heat Treat Supplier Receives Patent for Vacuum Furnace Control Thermocouple Read More »