When processing critical components, heat treaters value and demand precision in every step of the process — from the recipe to data collection — for the sake of accurate performance of the furnace, life expectancy of all equipment, as well as satisfactory delivery of a reliable part for the customer.

So what’s the obstacle to achieving those goals? Gunther Braus of dibalog GmbH/dibalog USA Inc. says, “The general problem is the human.” Indeed, the need to remove the variable of human fallibility plays a significant role in the search and development of equipment that could sense, read, and record data separate from any input from the operator. “As long there is a manual record of values there is the potential failure,” adds Braus.

Now, as part of the quest for precision, particularly in the automotive and aerospace industries, many control system requirements are driven by the need to prove process compliance to specified industry standards like CQI-9 and AMS 2750. These standards allow for and frequently require digital data records and digital proof of instrumentation precision.

With this in mind, Heat Treat Today asked six heat treat industry experts a controls-related question. Heat Treat Control Panel will be a periodic feature so if you have a control-related question you’d like addressed, please email it to Editor@HeatTreatToday.com and we’ll put your question to our control panel.

Q: As a heat treat industry control expert, what do you see as some of the best practices when it comes to digital data collection and storage and/or validation of instrumentation precision?

We thank those who responded: Andrew Bassett of Aerospace Testing & Pyrometry, Inc.; Gunther Braus, dibalog GmbH/dibalog USA Inc; Jim Oakes of Super Systems, Inc; Jason Schulze, Conrad Kascik Instrument Systems, Inc.; Peter Sherwin, Eurotherm by Schneider Electric; and Nathan Wright of C3Data.

Calibration and Collection

Jim Oakes (Super Systems Inc.) starts us off with an overview of the equipment review process, the crucial component of instrument calibration,  and digital data collection:

and digital data collection:

“Industry best practices are driven by standards defined by the company and customers they serve. Both the automotive and aerospace industries have a set of standards which are driven through self-assessments and periodic audits. Instrument precision is defined by the equipment’s use and is required to be checked during calibrations. The frequency of these calibration depends on the instrument and what kind of parts and processes it is responsible for.

The equipment used for these processes can be defined as field test instrumentation, controllers, and recording equipment. Calibration is required with a NIST-traceable instrument that has specific accuracy and error requirements. Before- and post-calibration readings are required (commonly identified as “as found” and “as left” recordings). During calibration, a sensitivity check is required on equipment and is recorded as pass/fail. The periodic calibration procedure is carried out not only on test equipment but also on control and recording equipment, to ensure instrument precision.

Digital data collection is a broad term with many approaches in heat treatment. As mentioned, requirements are driven by industry standards such as CQI-9 and AMS 2750. Specifically when it comes to digital data collection, electronic data must be validated for precision; checked; and calibrated periodically as defined by internal procedures or customer standards. Data must be protected from alteration, and have specific accuracy and precision. Best practice tends to be plant wide systems that cover the electronic datalogging that promotes ease of access to current and historical data allowing use for quality, operational, and maintenance personnel. Best practices in many cases are defined by the standards within each company, but the hard requirements are often the AMS 2750 and CQI-9 requirements for digital data storage.”

Industry Guidelines and Requirements

Andrew Bassett (Aerospace Testing & Pyrometry) has provided us with a reminder of the industry guidelines for aerospace manufacturing (via AMS-2750E, paragraph 3.2.7.1 – 3.2.7.1.5)

Andrew Bassett (Aerospace Testing & Pyrometry) has provided us with a reminder of the industry guidelines for aerospace manufacturing (via AMS-2750E, paragraph 3.2.7.1 – 3.2.7.1.5)

- The system must create electronic records that cannot be altered without detection.

- The system software and playback utilities shall provide a means of examining and/or compiling the record data, but shall not provide any means for altering the source data.

- The system shall provide the ability to generate accurate and complete copies of records in both human readable and electronic form suitable for inspection, review, and copying.

- The system shall be capable of providing evidence the record was reviewed – such as by recording an electronic review, or a method of printing the record for a physical marking indicating review.

- The system shall support protection, retention, and retrieval of accurate records throughout the record retention period. Ensure that the hardware and or software shall operate throughout the retention period as specified in paragraph 3.7.

- The system shall provide methods (e.g., passwords) to limit system access to only individuals whose authorization is documented.

“One of the biggest issues I see with one of these requirements will be point 5,” says Bassett. “The requirement is to be able to review these records throughout the retention period, which in some instances is indefinite. I always recommend to clients who may be upgrading or purchasing new digital systems that they should consider keeping a spare system in place to be able to satisfy this requirement. Who knows — today we are working on Windows 10, but in 50 years, will our successor be able to go back and review heat treat data when everything is run on Windows 28?”

“This is a topic that yields great discussions,” adds Jason Schulze (Conrad Kascik). He directs us to a challenge he sees from time to time.

“This is a topic that yields great discussions,” adds Jason Schulze (Conrad Kascik). He directs us to a challenge he sees from time to time.

Within the Nadcap AC7102/8 checklist, there is this question: “Do recorder printing and chart speeds meet the requirements of AMS 2750E Table 5 or more stringent customer requirements?” This correlates with AMS2750E, page 12, paragraph 3.2.1.1.2 “Process Recorder Print and Chart Speeds shall be in accordance with Table 5”.

“To ensure the proper use of an electronic data acquisition unit used on furnaces and ovens, these requirements must be understood,” continues Schulze. “Because this system is electronic, it should be designated a digital instrument and not an analog instrument. In doing so, this helps determine what requirements apply in Table 5. The only remaining requirement in Table 5 for digital instruments is ‘Print intervals shall be a minimum of 6 times during each time at temperature cycle. Print intervals shall not exceed 15 minutes.’

With this in mind, it is important to realize that, if your time at temperature cycles are short cycles (such as vacuum braze cycles), the sample rate of data collection may need to be adjusted to ensure it is recorded 6 times during the cycle.

As an example, if the shortest cycle processed is 4 minutes at temperature, a sample rate of every 60 seconds would not conform to AMS2750E because, in theory, the maximum amount of recordings would be 4 times during the time at soak. Now, if the sample rate was modified to every 30 seconds, this would allow ~8 recordings during the time at soak, which then would be conforming to AMS2750E.

Within the realm of electronic data acquisition on furnaces/ovens, this seems to be a frequent challenge for suppliers.”

A Critical Variable: Process Temperature

Nathan Wright (C3Data) agrees and zeroes in on process temperature as a critical variable to be measured:

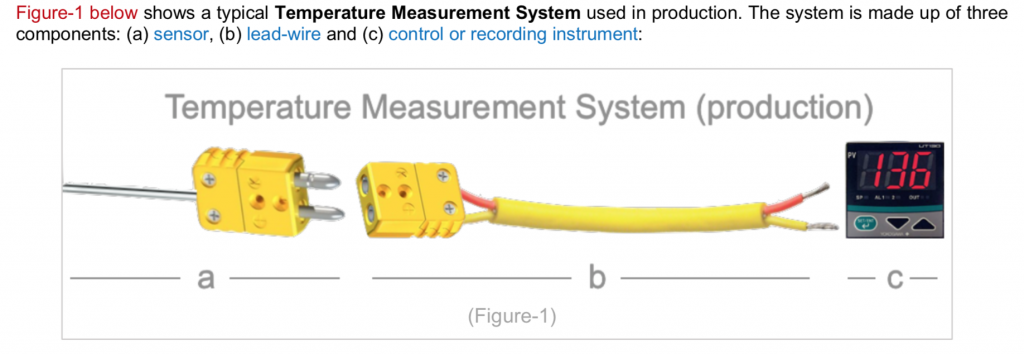

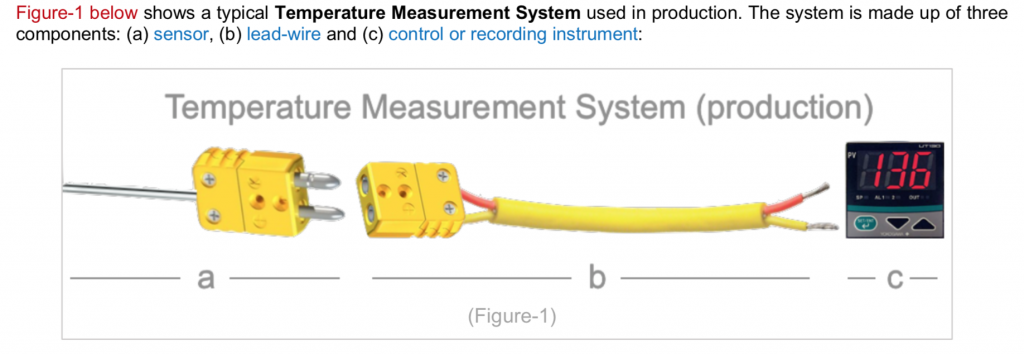

“No matter the heat-treating process being carried out, complying with AMS-2750 and/or CQI-9 requires that the heat treater measure, record, and control several different variables. One of the more common variables that must be measured, recorded, and controlled is process temperature.

Measuring process temperatures requires the use of a precise measurement system (Figure-1 below), and the accuracy of said measurement system must be periodically validated to ensure its ongoing compliance.”

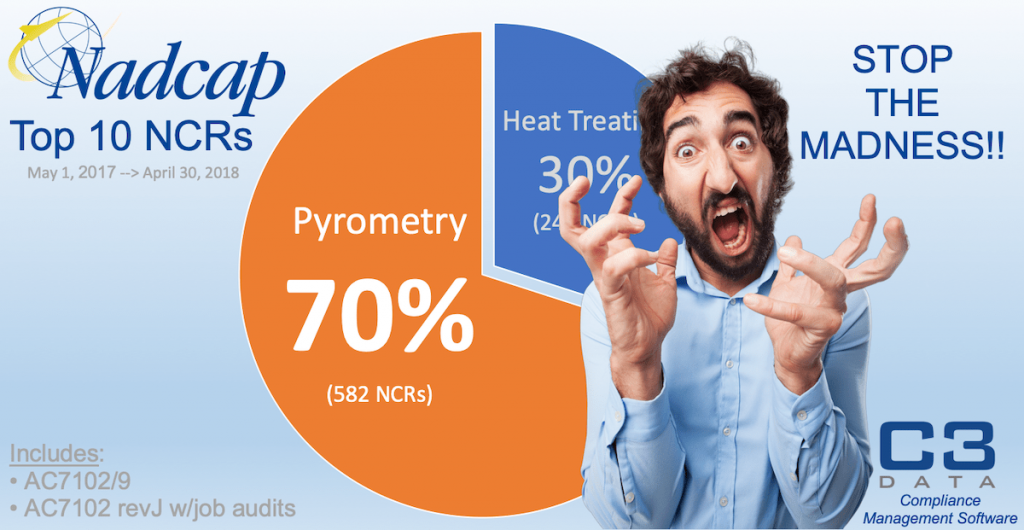

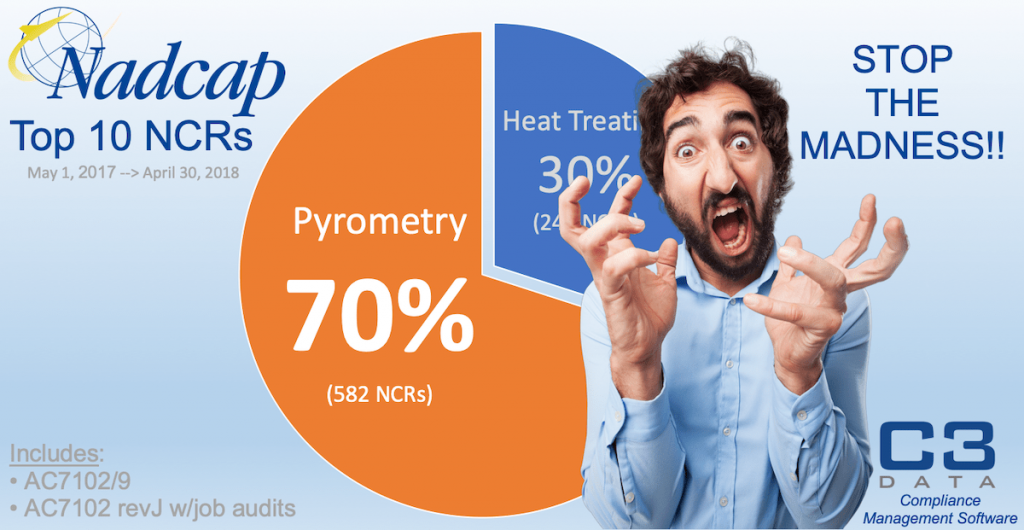

“The validation process is carried out through a series of pyrometric tests (Instrument Calibration and SAT), and historically these validation processes are highly error-prone.

In order to help ensure process instrumentation, process temperatures, and any other variable that impacts quality is properly validated it is good practice to begin automating compliance processes whenever and wherever possible. C3 Data helps automate all furnace compliance processes using software.”

A “Standard” Mindset

Gunther Braus (dibalog) chimes back in with some pertinent wisdom: “It is not sufficient only to record, you must live the standards like CQI-9, AMS, Nadcap or even your own standard you have set up, so you must survey the data. However, in the old times, there was a phrase: the one who measures, measures crap. In the end, it is all about surveillance of the captured data.

Gunther Braus (dibalog) chimes back in with some pertinent wisdom: “It is not sufficient only to record, you must live the standards like CQI-9, AMS, Nadcap or even your own standard you have set up, so you must survey the data. However, in the old times, there was a phrase: the one who measures, measures crap. In the end, it is all about surveillance of the captured data.

Where you store the data is a question of philosophy: personally, I prefer local storage in-house. Yes, we all talk about IOT, etc., and I do not want to start a discussion about security; it is more about accessing the data. No internet, no data. So simple. We are overly dependent upon cloud usage on the internet.

The automation of the instrumentation precision is so much effort in terms of automated communication between testing device and controller, from my point of view we are not there yet.”

A Look at the Standards In and Outside the Industry

Interesting question! writes Peter Sherwin (Eurotherm by Schneider Electric).

The aim is to record the true process temperature seen by the components being treated. However, there are many practical factors that can alter the accuracy of the reading. From the position of the thermocouple (TC), the TC accuracy (over time), suitability of the lead or extension wire, issues with CJC errors and instrument accuracy as well as electrical noise impacting the stability of the reading.

The standards do a good job to help by prescribing the location of TC, accuracies required for both TC and instrument, and frequent checks over time through TUS and SAT checks but note the specification requirements are maximum “errors”. And if you truly want to reach world-class levels of process control and reap the inherent benefits of better productivity and quality, you should aim to be well inside those tolerances allowed.

With 30yrs+ of data required to be stored (in certain cases, particularly aerospace), there should be some thought as to how and what form this should be stored in. There are many more options of storage when the data is in digital format.

- Paper is very costly to store and protect.

- The virgin data file should be secure and tamper-resistant and identical copies made for backup purposes held offsite.

- The use of FTP is becoming more common to move files automatically from the instrument to a local server (with its own backup procedures to ensure redundant records in case of disaster).

- Regular checks should be made to examine the availability and integrity of these electronic records.

- Control and Data Instrument suppliers should ideally have many years of supplying instrument digital records with systems that can access even the earliest of data record formats.

We also look outside of the heat treat standards for truly best practices. The FDA regulation 21CFRPart11 and associated GAMP Good Automated Manufacturing Practice have been extended with the new document “Data Integrity and Compliance with Drug cGMP, Questions and Answers, Guidance for Industry”. These updates leverage A.L.C.O.A to describe the key principles around electronic records (see below). This industry is also leading the requirement for sFTP a more secure format of the FTP protocol.

Heat Treat Today will run this column regularly featuring questions posed to and answered by industry experts about controls. If you have a question about controls and/or data as it pertains to heat treating, please submit it to doug@heattreattoday.com or editor@heattreattoday.com.

and digital data collection:

and digital data collection: Andrew Bassett (

Andrew Bassett ( “This is a topic that yields great discussions,” adds Jason Schulze (

“This is a topic that yields great discussions,” adds Jason Schulze (

Gunther Braus (

Gunther Braus (